Constant temperature control method and constant temperature control system for power frequency skin-effect tracing system

A technology of constant temperature control and integrated skin, which is applied in the direction of temperature control using electric mode, auxiliary controller with auxiliary heating device, etc., which can solve the problems of heat waste, power supply transformer and load impact, outlet temperature fluctuation, etc., and achieve reduction The effect of on-off times, ensuring control accuracy, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

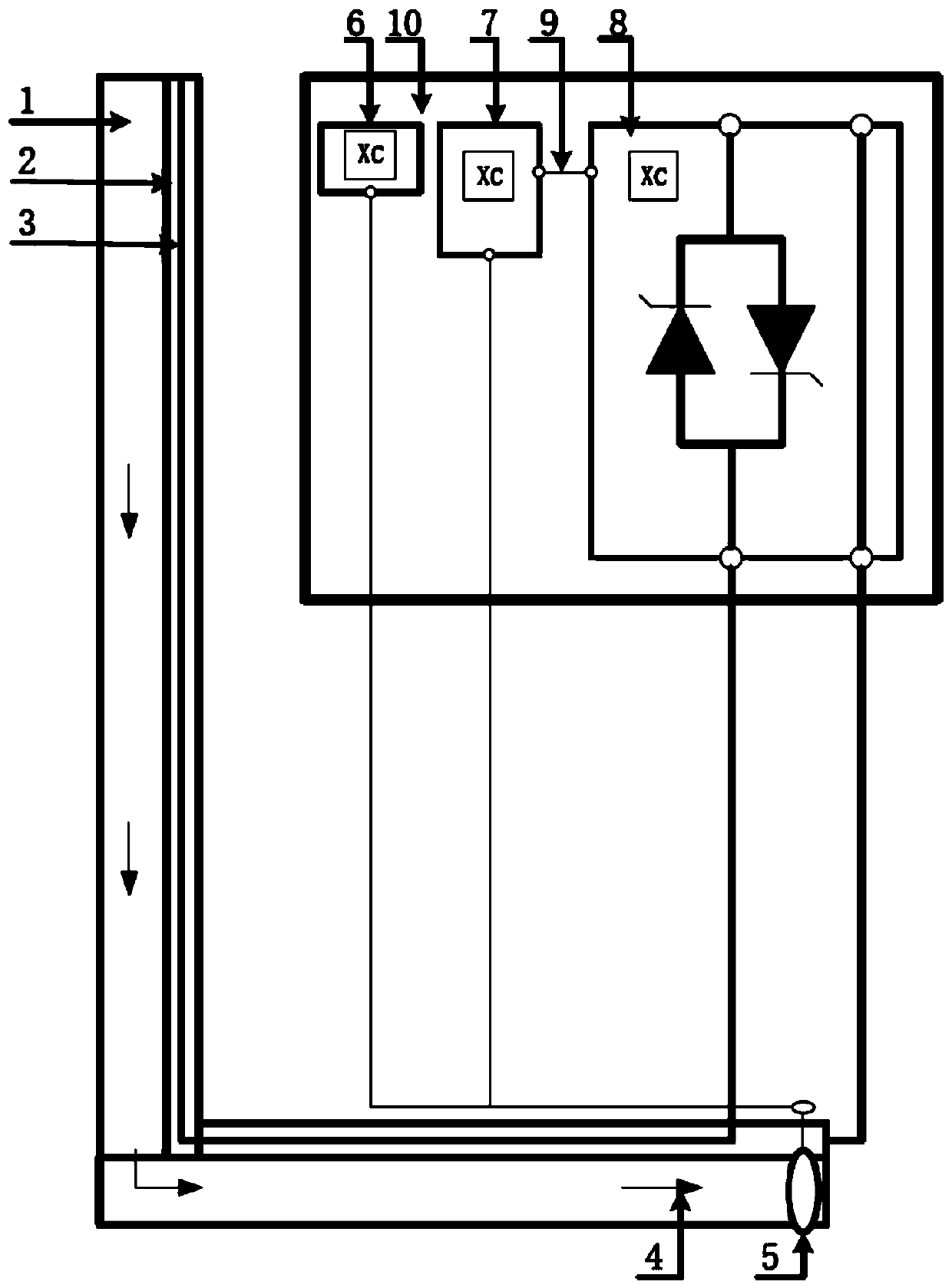

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

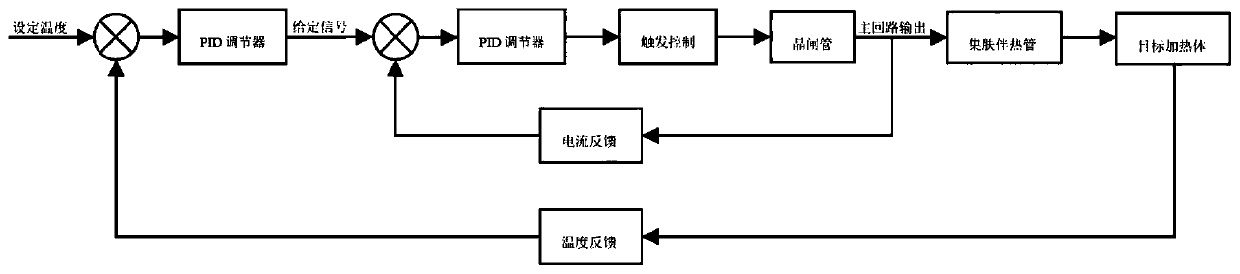

[0035] like figure 2 As shown, a method for constant temperature control of a power frequency skin tracing system includes the following steps:

[0036] Step 1), regularly collect the current temperature of the target heating body at the outlet of the infusion tube, and calculate the temperature difference e(k) between the current temperature and the set temperature target;

[0037] Step 2), obtain the power controller output Δu(k) through PID calculation according to the obtained current temperature difference e(k);

[0038] Δu(k)=Kp[e(k)-e(k-1)]+Kie(k)+Kd[e(k)-2e(k-1)+e(k-2)];

[0039] e(k-1) and e(k-2) are the temperature difference value of the upper frame and the temperature difference value of the upper frame respectively; Kp is a proportional parameter, Ki is an integral parameter, and Kd is a differential parameter;

[0040] Finally, the output current I of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com