Double temperature double control wine cabinet evaporator

A technology of evaporator and plate evaporator, which is applied in the direction of evaporator/condenser, refrigerator, lighting and heating equipment, etc. It can solve the problems of unfavorable air front and back convection, unfavorable heat exchange between evaporator and refrigerator, and achieve air circulation Good effect, improve cooling efficiency and increase utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

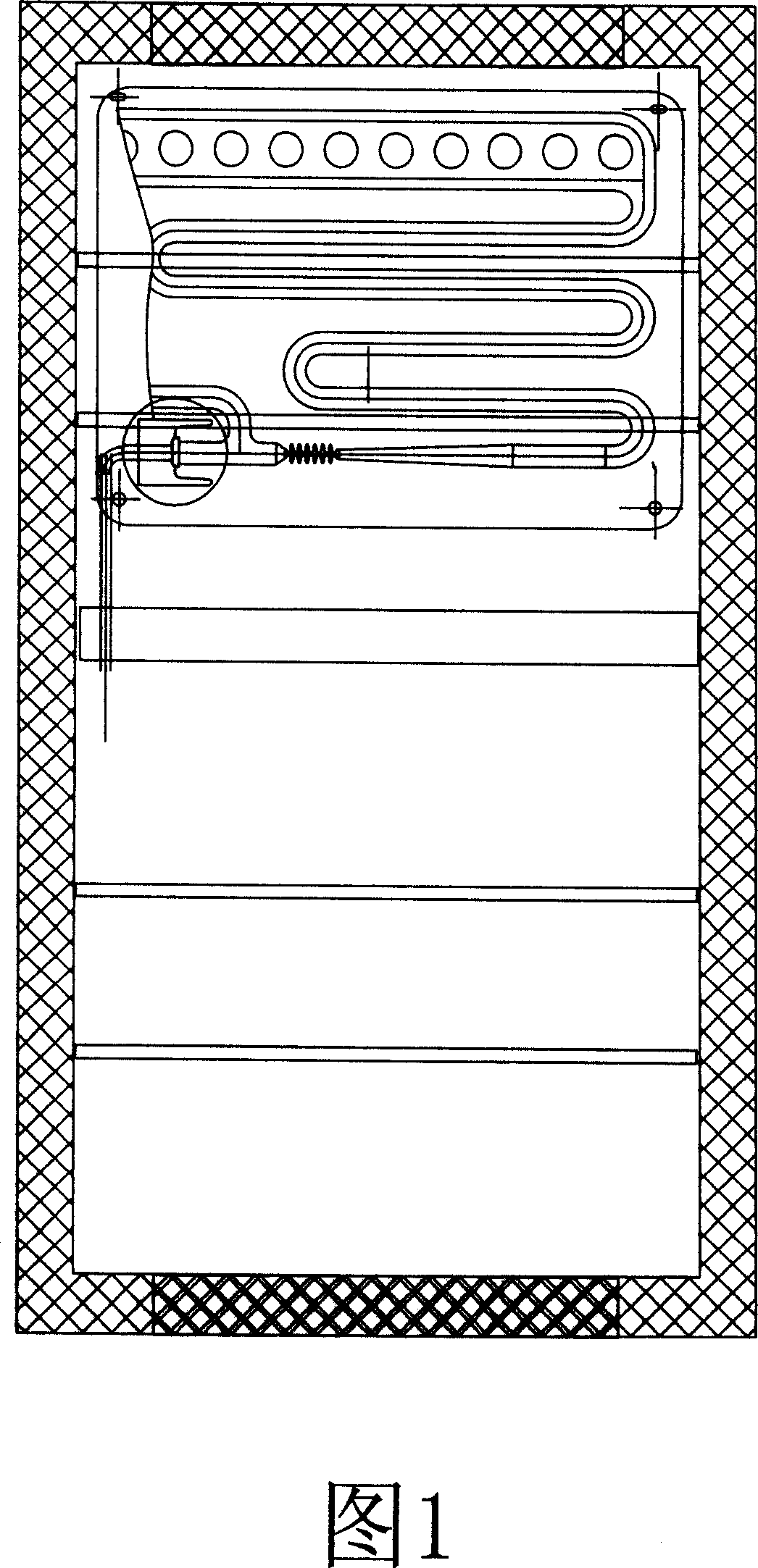

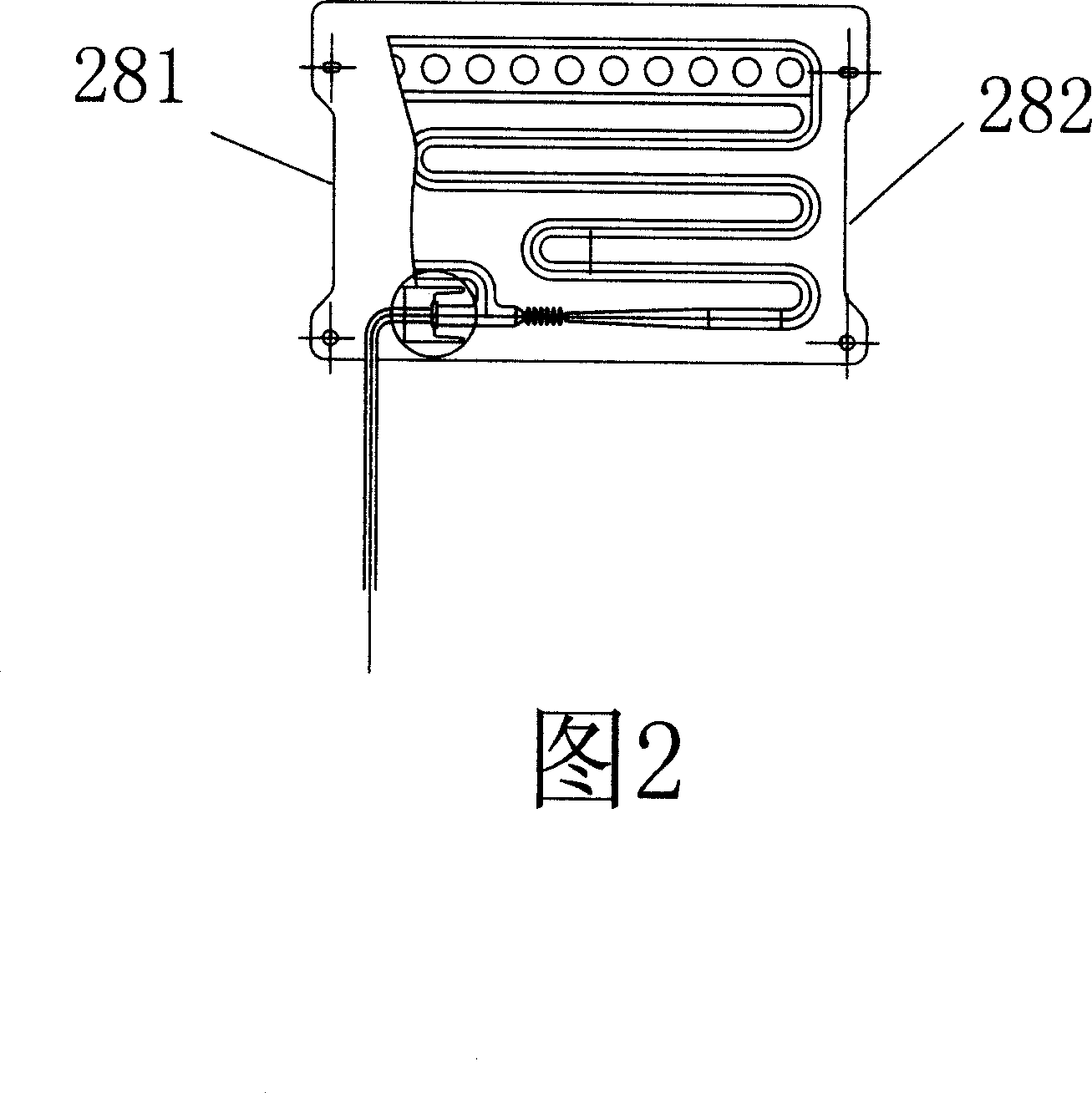

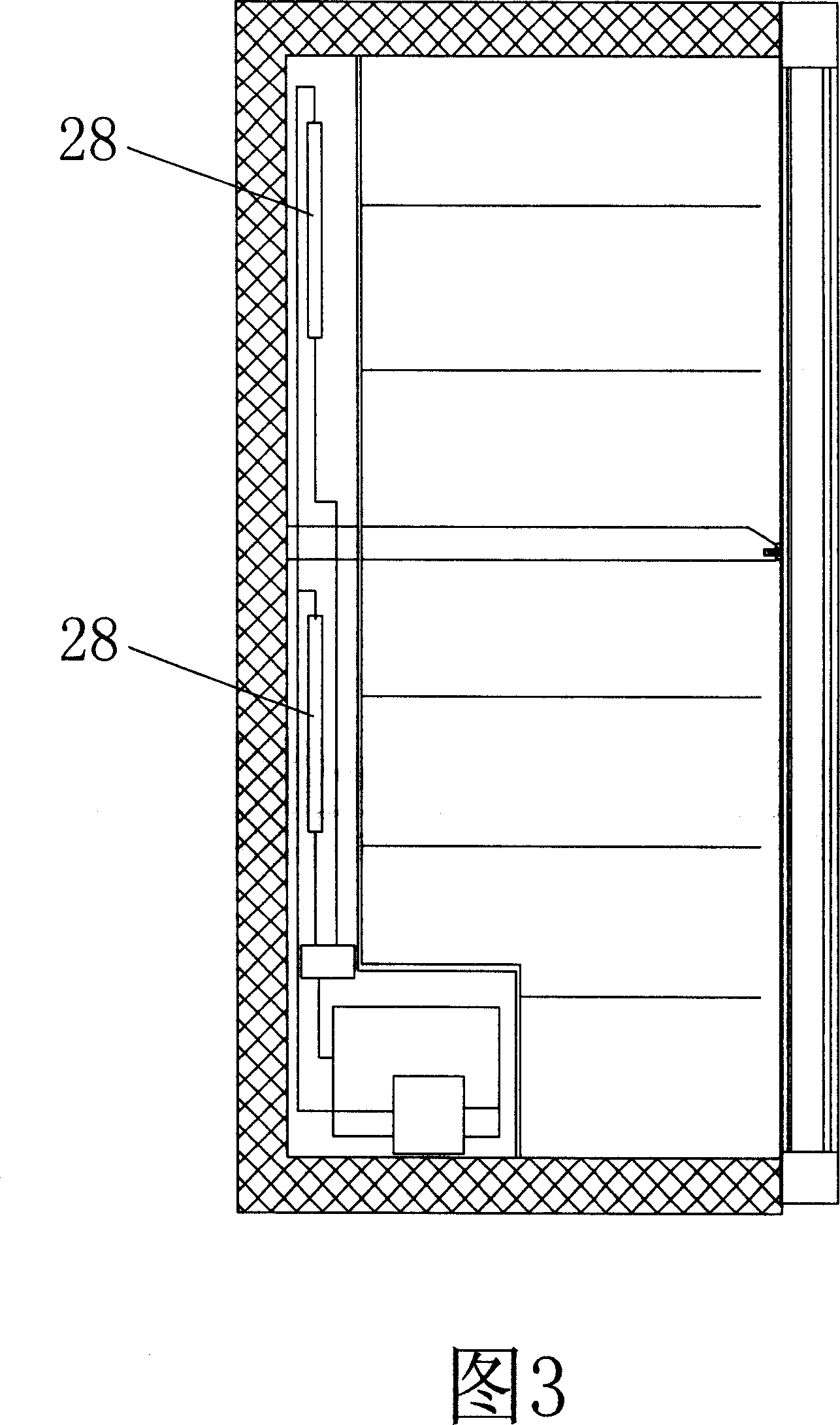

[0032] As shown in Figures 2 and 3, the present invention provides a dual-temperature dual-control wine cabinet evaporator 28. The components on the plate are the same as those in the prior art. The evaporator is an inflatable evaporator or a plate evaporator. At least one ventilation slot 281, 282 is provided on the side of the inflatable evaporator or the plate evaporator. In FIG. 2, there are two symmetrical ventilation slots 281 and 282.

[0033] When there are multiple ventilation slots, they are evenly distributed symmetrically or asymmetrically on both sides of the evaporator.

[0034] The evaporator described is a flooded evaporator. The refrigerant in the evaporator pipeline flows from bottom to top.

[0035] As an improvement, there are the following embodiments.

Embodiment 2

[0037] The cross-sectional shape of the ventilation slot is wedge-shaped, dovetail-shaped, elliptical, rectangular, U-shaped and other regular or irregular geometric figures as shown in Figs. 4, 5, 6, 7, and 8.

Embodiment 3

[0039] There is at least one piece of fin extending from the ventilation slot, for example, its cross-sectional shape is M-shaped or "comb"-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com