Cooling holder rod and cigarette incombustible in heating

A nozzle stick and cooling section technology, applied in the field of cooling nozzle sticks and heat-not-burn cigarettes, can solve the problems of scalding the mouth of smoke, insufficient cracking of tobacco substances, and decreased release of aroma components, and achieve excellent water vapor. Adsorption capacity, ensure the amount of smoke and smoke, and enhance the effect of hot feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

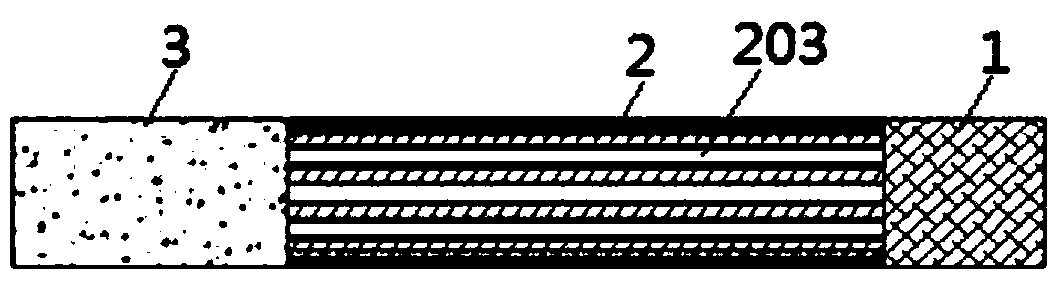

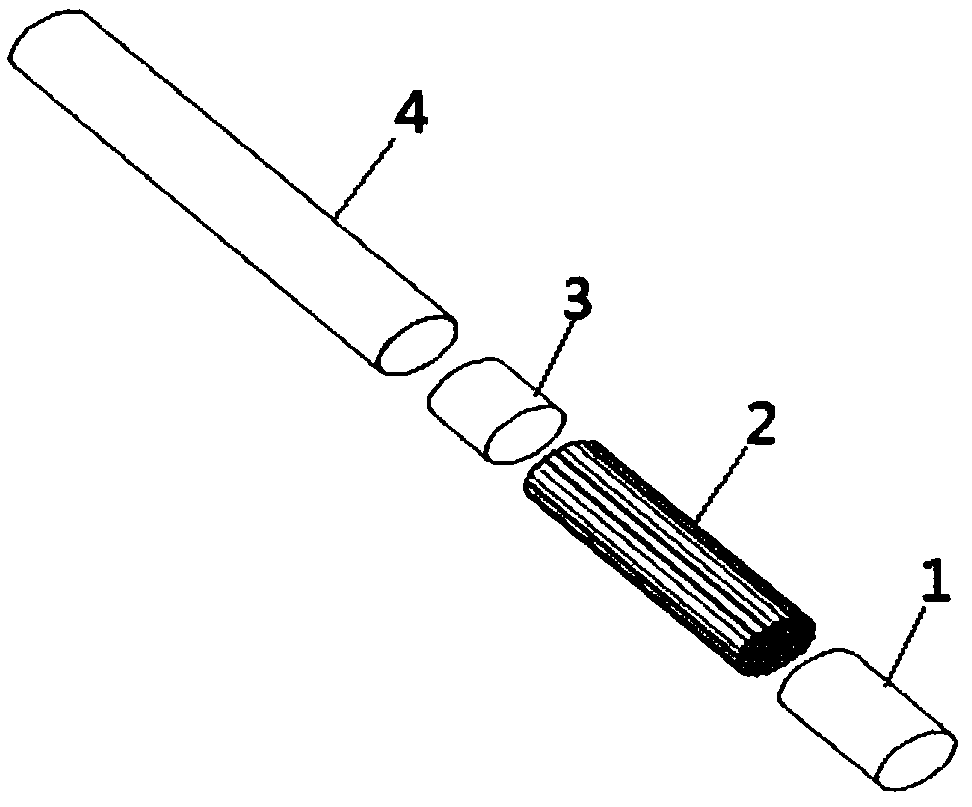

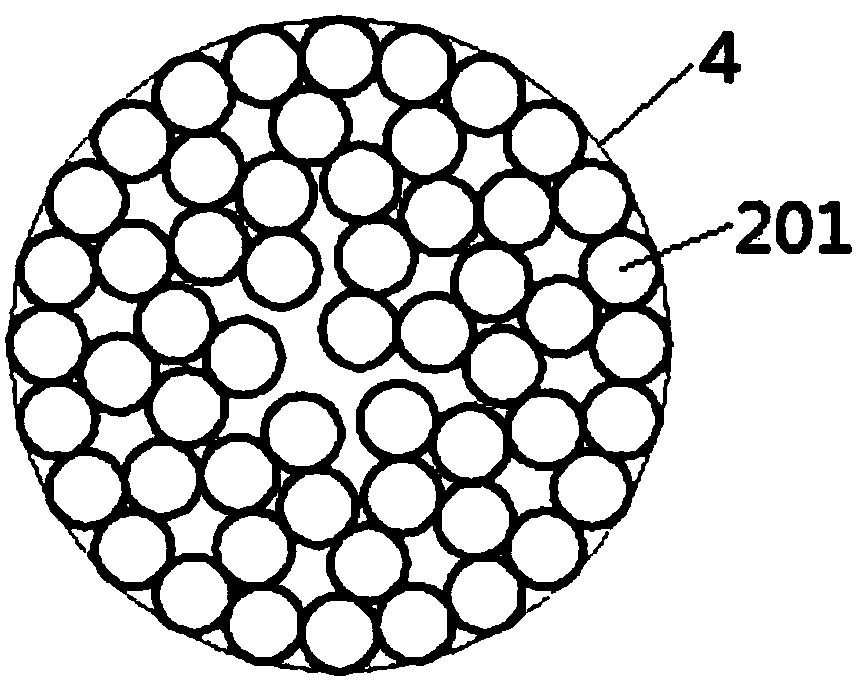

[0047] Such as figure 1 As shown, a heat-not-burn cigarette includes sequentially connected filter section 1, cooling section 2 and smoking section 3, and the filtering section 1 and cooling section 2 form the main part of the cooling tip rod, and the filtering section is composed of cooling and It consists of a special acetate filter rod with low smoke interception, and the cooling section is formed by wrapping a columnar structure formed by a plurality of first rods 201 with the outer packaging layer 4, and the surface of the first rods is coated with a cooling material. The first rod is a cylindrical barrel, and the flue gas flow channel 203 is mainly composed of through holes in the first rod and gaps between the first rods.

[0048] Wherein, the first rod is a round rod with an outer diameter of 0.3 mm.

[0049] The first rod is made of a cellulose paper material with a low absorbent capacity. The quantitative of the cellulose paper is 100g / m 2 .

[0050] The cooling ...

Embodiment 2

[0055] Example 1 was repeated, only changing the outer diameter of the first rod to 0.5 mm. Through comparative research, it was found that the highest flue gas temperature at the inlet was 43°C, which was 20°C lower than that of iQOS; at the same time, the total particulate matter in the flue gas was 16.0 mg / piece, which was 16.0 mg per stick, which was 20°C lower than that of iQOS flue gas. The temperature of the inlet flue gas was significantly reduced, and the amount of smoke at the inlet flue gas was also increased, achieving the effect of lowering the temperature and lowering the retention of flue gas (see Table 1 for the results).

Embodiment 3

[0057] Example 1 was repeated, changing only the outer diameter of the first rod to 0.8 mm. A comparative study found that the maximum flue gas temperature at the inlet was 45°C, which was 18°C lower than that of iQOS; at the same time, the total particulate matter in the flue gas was 16.3 mg / piece, which was 16.3 mg per stick, which was 18°C lower than that of the iQOS flue gas. The phase matter increased by 1.1 mg / stick, the temperature of the inlet flue gas decreased significantly, and the amount of smoke at the inlet flue gas also increased, achieving the effect of lowering the temperature and lowering the retention of flue gas (see Table 1 for results).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com