Novel fragrant heat-not-burn cigarette and preparation method thereof

A heat-not-burn and cigarette technology, applied in tobacco, e-liquid filter elements, applications, etc., can solve the problems of loss of flavor and fragrance, poor absorption capacity of tobacco raw materials, loss of flavor, etc., and achieve long-lasting fragrance, less volatilization and effective release, Effect of lowering flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

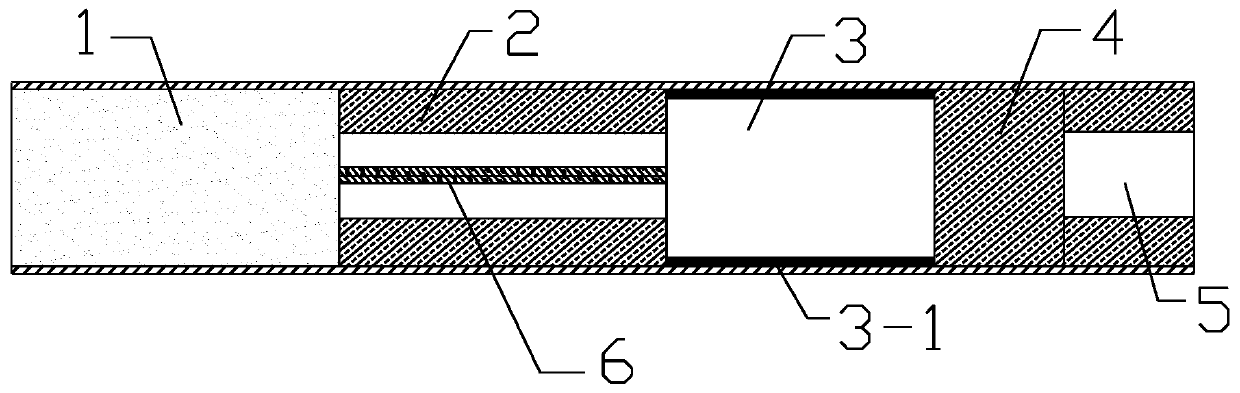

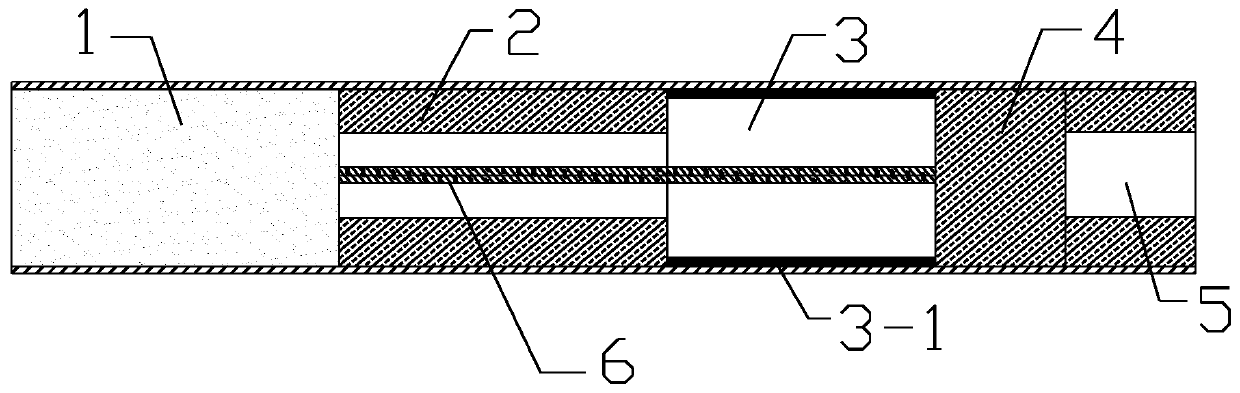

[0028] What embodiment 1 provides is a kind of novel heat-not-burn cigarette of control sample, and it is specifically 10 parts of N-ethyl-p-menthyl-3-carboxamide (mint), 5 parts of bergamot oil, 60 parts of peppermint oil , 10 parts of eucalyptol, 10 parts of linalool, and 5 parts of ethanol are mixed evenly to form an essence; The preparation method prepares the tobacco sheet for the new heat-not-burn cigarette, cuts it into shreds and rolls it into the tobacco material section of the heat-not-burn cigarette, and then prepares the heat-not-burn cigarette A with the prepared composite filter.

Embodiment 2

[0029] Example 2 provides a mint-flavored novel heat-not-burn cigarette, the specific preparation method of which is as follows:

[0030] (1) According to the following formula of parts by weight, flavoring essence is configured: 10 parts of N-ethyl-p-menthyl-3-carboxamide (peppermint), 5 parts of bergamot oil, 60 parts of peppermint oil, 10 parts of eucalyptol , 10 parts of linalool, 5 parts of ethanol; above-mentioned raw material is mixed uniformly and is mixed with peppermint fragrance and flavor essence;

[0031] (2) 50 parts of gelatin, 20 parts of carboxymethyl chitosan and 45 parts of sodium alginate are dissolved in hot water at 55°C, and configured into a wall material solution with a solution concentration of 1.2%, and then 110 parts of essence are added. Emulsify under continuous stirring at 750rpm for 15min, keep the solution temperature at 35°C, add 10% citric acid solution to slowly adjust the pH to 4.0, stir at a constant temperature at 500rpm for 25min, then r...

Embodiment 3

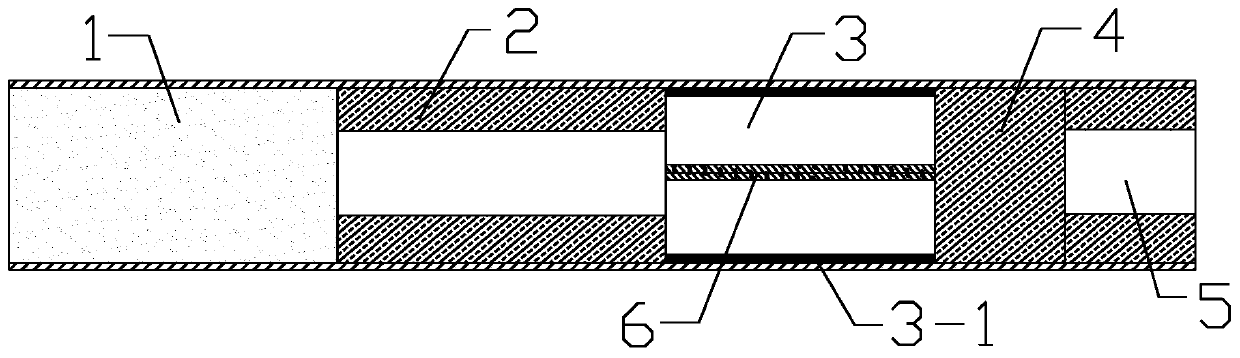

[0034] Example 3: The preparation method of the fragrant tow is as in step (1) to step (3) in Example 2, and then when preparing the cooling rod of the heat-not-burn cigarette, the fragrant tow is placed in the hollow of the cooling rod part, and prepared as a heat-not-burn cigarette C, the specific structure is as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com