Anhydrous fracturing fluid suitable for unconventional reservoir fracturing and preparing method of anhydrous fracturing fluid

A technology for waterless fracturing fluid and reservoir pressure, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex preparation process, slow gelation speed, poor temperature resistance, etc., and achieve simplified preparation Process, improved temperature resistance, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

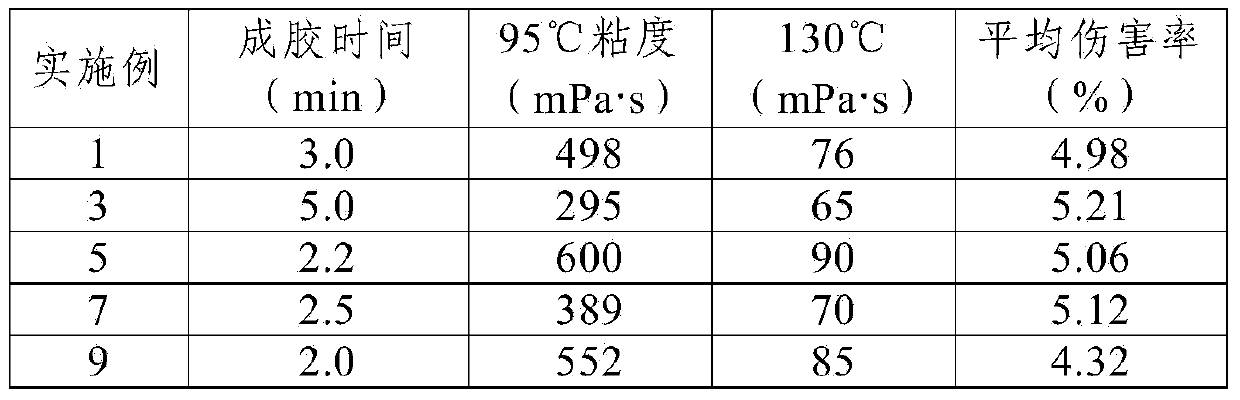

Embodiment 1

[0027] The anhydrous fracturing fluid suitable for shale gas layer fracturing in this embodiment is made of the following raw materials in mass percentage: 1.0% gelling agent, 2.0% micelle accelerator, 0.1% temperature stabilizer, and the balance is alkane base hydrocarbons; the temperature stabilizer is sulfamic acid, and the alkyl hydrocarbons are propane; the gelling agent is dialkyl iron phosphate, and the mixed alcohol in dialkyl iron phosphate includes methanol, n-hexanol and decathanol Diol, the mass percentage of methanol in the mixed alcohol is 25%, the mass percentage of n-hexanol is 70%, and the mass percentage of dodecanol is 5%; The preparation method of ionic organic complexes and micellar accelerators is as follows: react anhydrous ferric sulfate and oleic acid triethanolamine at 60°C for 3 hours, and then mix the reaction product with ethylene glycol monobutyl ether to obtain micellar accelerators. Agent, the mol ratio of oleic acid triethanolamine and iron ion...

Embodiment 2

[0033] The present embodiment is the same as Example 1, except that the temperature stabilizer used is dodecylbenzenesulfonic acid, and the alkyl hydrocarbons are butane or pentane, or are propane, butane and pentane At least two, low carbon alkanol is C 1 -C 4 At least two of the alkyl alcohols, or ethanol, propanol or butanol, the medium and long chain alkyl alcohol is C 6 -C 10 At least two of the alkyl alcohols, or C 7 -C 10 One of the alkyl alcohols, the long-chain alkyl alcohol is C 12 -C 16 At least two of the alkyl alcohols, or C 13 -C 16 One of the alkanols.

Embodiment 3

[0035] The anhydrous fracturing fluid suitable for shale gas layer fracturing in this embodiment is made of the following raw materials in mass percentage: 2.0% gelling agent, 4.0% micelle accelerator, 0.5% temperature stabilizer, and the balance is alkane base hydrocarbons; the temperature stabilizer is dodecylbenzenesulfonic acid, and the alkyl hydrocarbons are propane, butane and pentane (molar ratio 1:1:2); the gelling agent is dialkyl phosphoric acid Ester iron, the mixed alcohol in dialkyl phosphate iron comprises propanol, octanol and myristyl alcohol, and the mass percentage composition of propanol is 40% in the mixed alcohol, and the mass percentage composition of octanol is 40%, tetradecyl alcohol The mass percentage of alcohol is 20%; the micelle accelerator is an organic complex containing trivalent aluminum ions, and the preparation method of the micelle accelerator is: react aluminum chloride and triethanolamine oleate at 50°C 5h, then the reaction product is mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com