Method for producing precipitate silicon dioxide by using sodium bicarbonate to control supersaturation degree

A technology for precipitating silica and sodium bicarbonate, which is applied in the direction of silica, etc., can solve problems such as corrosion of equipment, harm to human health, and low precipitation reaction efficiency, and achieve convenient operation, uniform particle size distribution, and strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

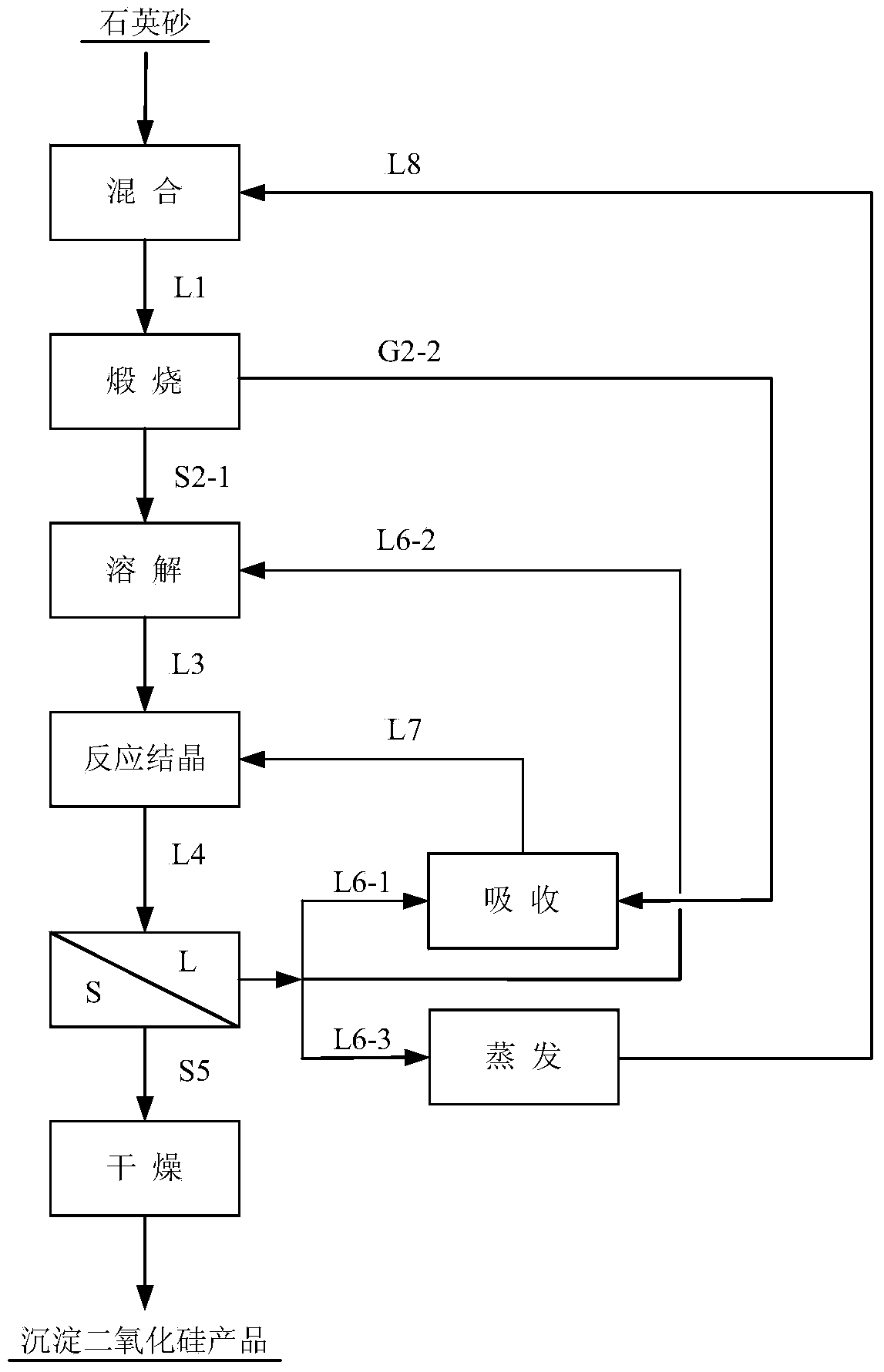

Method used

Image

Examples

Embodiment 1

[0047] Mix 600g of quartz sand with 1270g of soda ash, and calcinate at 1300°C for 60 minutes to obtain 1205g of solid sodium silicate, while recovering CO 2 . Solid sodium silicate was dissolved in sodium carbonate solution to obtain 1.2mol / L sodium silicate solution.

[0048] Put 500mL of sodium silicate solution in a 10L crystallization reactor, control the temperature at 40°C, turn on the stirrer, and add a sodium bicarbonate solution with a concentration of 2.7mol / L dropwise with a peristaltic pump. By adjusting the drop rate of the solution and To control the degree of supersaturation, a total of 700 mL of sodium bicarbonate solution was added dropwise to precipitate hydrated silica.

[0049] The suspension in the crystallization reactor was filtered. Filter to obtain 1160mL sodium carbonate solution, wherein 500mL sodium carbonate solution absorbs CO 2 Gas, get 2.7mol / L sodium bicarbonate solution, return to the peristaltic pump for recycling; 300mL sodium carbonate ...

Embodiment 2

[0051] Mix 1,000g of quartz sand with 2,650g of soda ash, and calcinate at 1,350°C for 60 minutes to obtain 1,880g of solid sodium silicate, while recovering CO 2 . Solid sodium silicate was dissolved in sodium carbonate solution to obtain 1.2mol / L sodium silicate solution.

[0052] Put 800mL of sodium silicate solution in a 10L crystallization reactor, control the temperature at 45°C, turn on the stirrer, and use a peristaltic pump to add dropwise a sodium bicarbonate solution with a concentration of 2.7mol / L. By adjusting the drop rate of the solution and To control the degree of supersaturation, a total of 1120 mL of sodium bicarbonate solution was added dropwise to precipitate hydrated silica.

[0053] The suspension in the crystallization reactor was filtered. Filter to obtain 1870mL sodium carbonate solution, wherein 800mL sodium carbonate solution absorbs CO 2 Gas, get 2.7mol / L sodium bicarbonate solution, return to the peristaltic pump for recycling; 500mL sodium ca...

Embodiment 3

[0055] Mix 1,000g of quartz sand with 3,000g of soda ash, and calcinate at 1,400°C for 60 minutes to obtain 1,975g of solid sodium silicate, while recovering CO 2 . Solid sodium silicate was dissolved in sodium carbonate solution to obtain 1.2mol / L sodium silicate solution.

[0056] Put 1000mL of sodium silicate solution in a 10L crystallization reactor, control the temperature at 50°C, turn on the stirrer, and use a peristaltic pump to add dropwise a sodium bicarbonate solution with a concentration of 2.7mol / L. By adjusting the drop rate of the solution and To control the degree of supersaturation, a total of 1400 mL of sodium bicarbonate solution was added dropwise to precipitate hydrated silica.

[0057] The suspension in the crystallization reactor was filtered. Filter to obtain 2275mL sodium carbonate solution, wherein 1000mL sodium carbonate solution absorbs CO 2 Gas, get 2.7mol / L sodium bicarbonate solution, return to the peristaltic pump for recycling; 600mL sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com