Pre-treatment method used for preparing biodiesel from swill oil and trench oil

A biodiesel and gutter oil technology, applied in biofuel, petroleum industry, fatty acid production, etc., can solve problems such as process instability, incomplete reaction, catalyst failure, etc., achieve obvious overall economic effect, reduce garbage discharge, and improve oil quality Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with the embodiments.

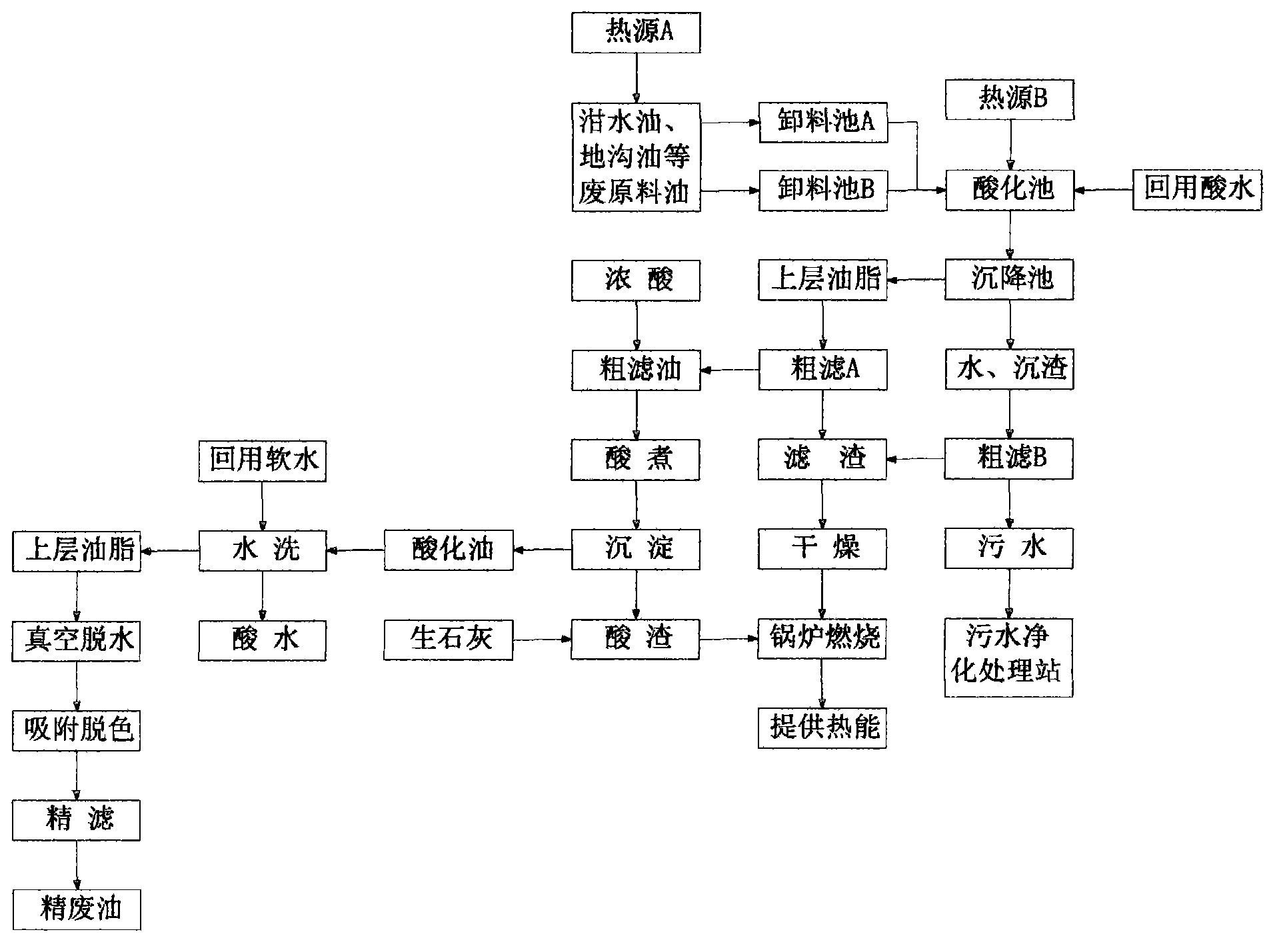

[0032] See figure 1 The process steps of the present invention are as follows: buy waste oil, swill oil, etc. that are acceptable through laboratory tests and technical and economic calculations as waste raw material oils, transport them by tankers or drums, direct steam purging, dump or pass through filters The pump assists in unloading into the unloading tank. Two discharge tanks (discharge tank A, discharge tank B) are used alternately. One is used and one is prepared, and the material is discharged alternately when full. When the unloading tank has a large storage capacity, the steam (heat source A) is indirectly heated to keep the waste oil in a liquid state.

[0033] A height-adjustable submersible pump with a filter screen is used to pump material into the acidification tank, and about 20% by mass of acid water (which can be acid-containing wastewater, which saves costs) is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com