Co-production method and system of ammonium phosphate and magnesium hydrate

A technology of magnesium hydroxide and ammonium phosphate, applied in the directions of magnesium hydroxide, phosphorus oxyacid, phosphate, etc., can solve the problems of high energy consumption and large phosphorus loss, achieve economical rationality, small phosphorus loss, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

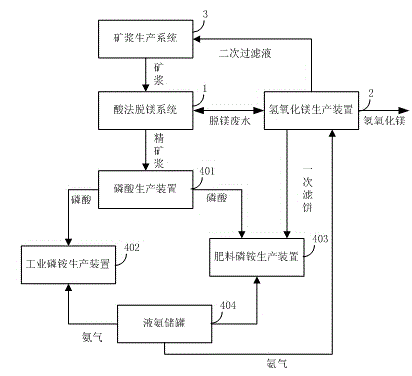

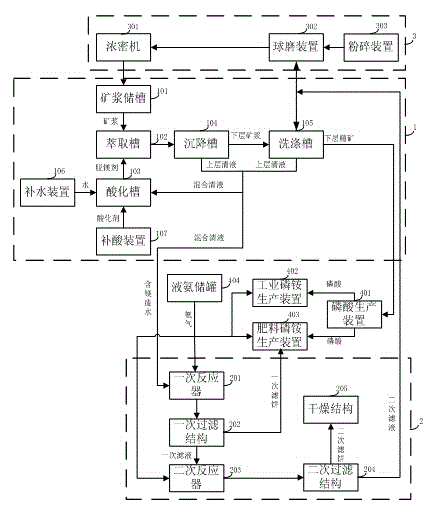

[0040] see figure 1 and 2 , the embodiment of the present invention provides a method for the co-production of ammonium phosphate and magnesium hydroxide, the method comprising the following steps:

[0041] (1) Demagnesization by flotation: Make magnesium-containing phosphate rock pulp (raw ore pulp as shown in Table 1) into a slurry with a mass concentration of 35% water, raise the temperature to 60°C, and add magnesium removal agent ( The concentration of the demagnesizing agent is 12%, the molar ratio of MgO (dry basis) to the demagnesizing agent in the slurry is 1:2.3), the reaction time is 2 hours, the pH of the final slurry is controlled to be about 4.7, and the solid-liquid Separation, the liquid phase is magnesium removal wastewater, and the solid phase is concentrate pulp (the content of magnesium and phosphorus after washing is shown in Table 1 and Table 2).

[0042] Table 1

[0043]

[0044] Table 2

[0045]

[0046] ...

Embodiment 2

[0059] Example 2 On the basis of Example 1, the concentration of the magnesium removal agent, the continuous operation time of the magnesium removal reaction, the secondary precipitation reaction time and the pH parameters of the secondary precipitation reaction are discussed, so as to maximize the effect of magnesium removal And reduce phosphorus loss, and obtain magnesium hydroxide product with high yield and purity.

[0060] (1) Influence of the concentration of demagnesizing agent

[0061] In phosphate rock (P 2 o 5 is 29.1%, MgO is 2.04%), the molar ratio of MgO demagnesizing agent is 1:2.3, the pulp concentration (containing H 2 O) Under certain conditions, the reaction time is 2h, and the reaction temperature is 50°C, the concentration of magnesium removal agent and the amount of magnesium removal agent are changed. The experimental results are shown in Table 3:

[0062] table 3

[0063]

[0064] (2) The influence of the continuous operation time of the magnesium...

Embodiment 3

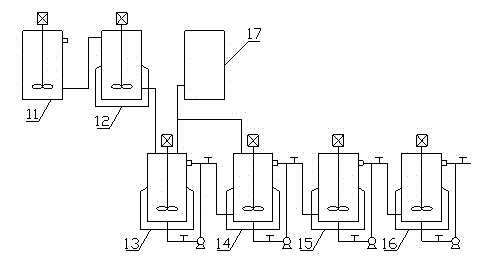

[0085] see figure 1 and 2 , the embodiment of the present invention provides a co-production system of ammonium phosphate and magnesium hydroxide, the system includes a pulp production system 3, an acid method demagnesization system 1, a phosphoric acid production device 401, an ammonium phosphate production device (including an industrial ammonium phosphate production device 401 and / or industrial ammonium phosphate production unit 402), liquid ammonia storage tank 404 and magnesium hydroxide production unit 2, etc. Among them, the pulp production system 3 is connected with the acid method magnesium removal system 1 through pipelines, the concentrate pulp output end of the acid method magnesium removal system 1 is connected with the phosphoric acid production device 401 through pipelines, and the magnesium removal wastewater of the acid method magnesium removal system 1 The output end is connected with the magnesium hydroxide production device 2 through pipelines. At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com