Phosphorite comprehensive utilization method

A technology of phosphate rock and phosphoric acid, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as reducing the practical effect of phosphorus-containing fertilizers on crops and affecting the purity of calcium compounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

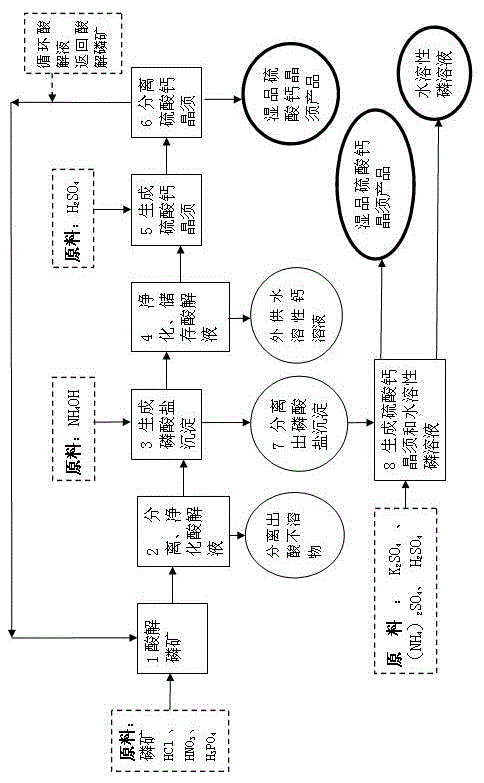

Image

Examples

Embodiment 1

[0097] Embodiment 1: the present invention uses the application of sulfuric acid acid hydrolysis phosphate rock

[0098] Use sulfuric acid to decompose phosphate rock to produce ammonium phosphate and phosphate, and increase the circulating medium HCl and HNO on the basis of the raw materials used in the current process 3 、H 3 PO 4 , acetic acid or its mixed acid in any proportion can promote the present invention to realize the complete comprehensive utilization of raw materials. Its innovation and practicability are reflected in the fact that no matter the grade of phosphate rock or the amount of impurities, it will not affect the quality of high-purity calcium compounds and phosphorus products. Combining with the current ammonium phosphate process, the present invention can not only obtain highly pure calcium product, but also provide it with concentrated phosphoric acid or phosphate without evaporation and concentration.

[0099] Description of implementation steps: ...

Embodiment 2

[0121] Embodiment 2: the present invention is applied to the production of feed grade calcium hydrogen phosphate

[0122] In this example, the innovation and practicability of the present invention are reflected in the fact that under the condition of using sulfuric acid and phosphate rock as the main raw materials, feed-grade calcium hydrogen phosphate is acid-hydrolyzed in a closed-loop acid hydrolysis method, and the raw materials are completely comprehensively utilized . Compared with the existing feed calcium hydrogen phosphate process, because ammonia water is used in the neutralizing acid solution in the present invention, what is obtained by removing fluorine compounds is a high-concentration slow-release nitrogen-phosphorus compound fertilizer.

[0123] Description of implementation steps:

[0124] a. React with acid and phosphate rock to generate an acid solution containing water-soluble calcium and water-soluble phosphorus;

[0125] The acid of present embodimen...

Embodiment 3

[0144] Reality Embodiment 3: the present invention uses HCl as the acid-lysis phosphate rock process of raw material

[0145] Implementation purpose:

[0146] Relying on the process of phosphorus-free products and using HNO 3 1. When HCl is the raw material for acid hydrolysis of phosphate rock, this embodiment focuses on adopting various processes and products with high economic benefits, low energy consumption, and low investment to form a new process for comprehensive utilization with high benefits.

[0147] The main purpose of using HCl to decompose phosphate rock is to accept by-product HCl (gas) or dilute hydrochloric acid, and use a large amount of by-product hydrochloric acid to acidify low-grade phosphate rock to obtain phosphorus products and industrial-grade calcium products;

[0148] Acid concentration: Acid hydrolysis of phosphate rock with HCl is an open-loop acid hydrolysis method. The acid concentration is preferably 6-12mol / l, and a high concentration is be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com