Acidolysis method of magnesium-containing phosphate rock

A technology of phosphate rock and acid hydrolysis, applied in ammonium sulfate, chemical instruments and methods, phosphorus compounds, etc., can solve the problem of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

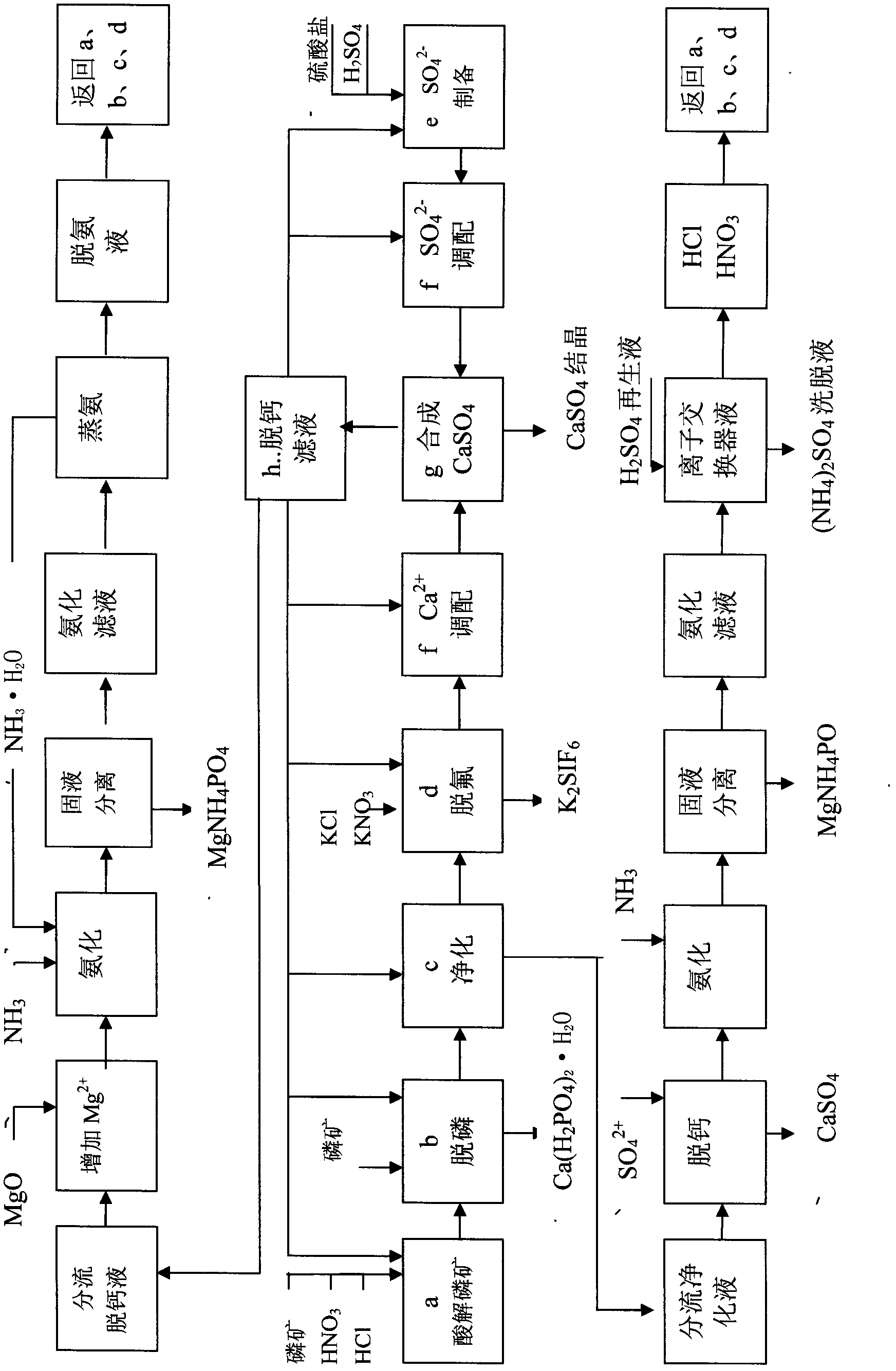

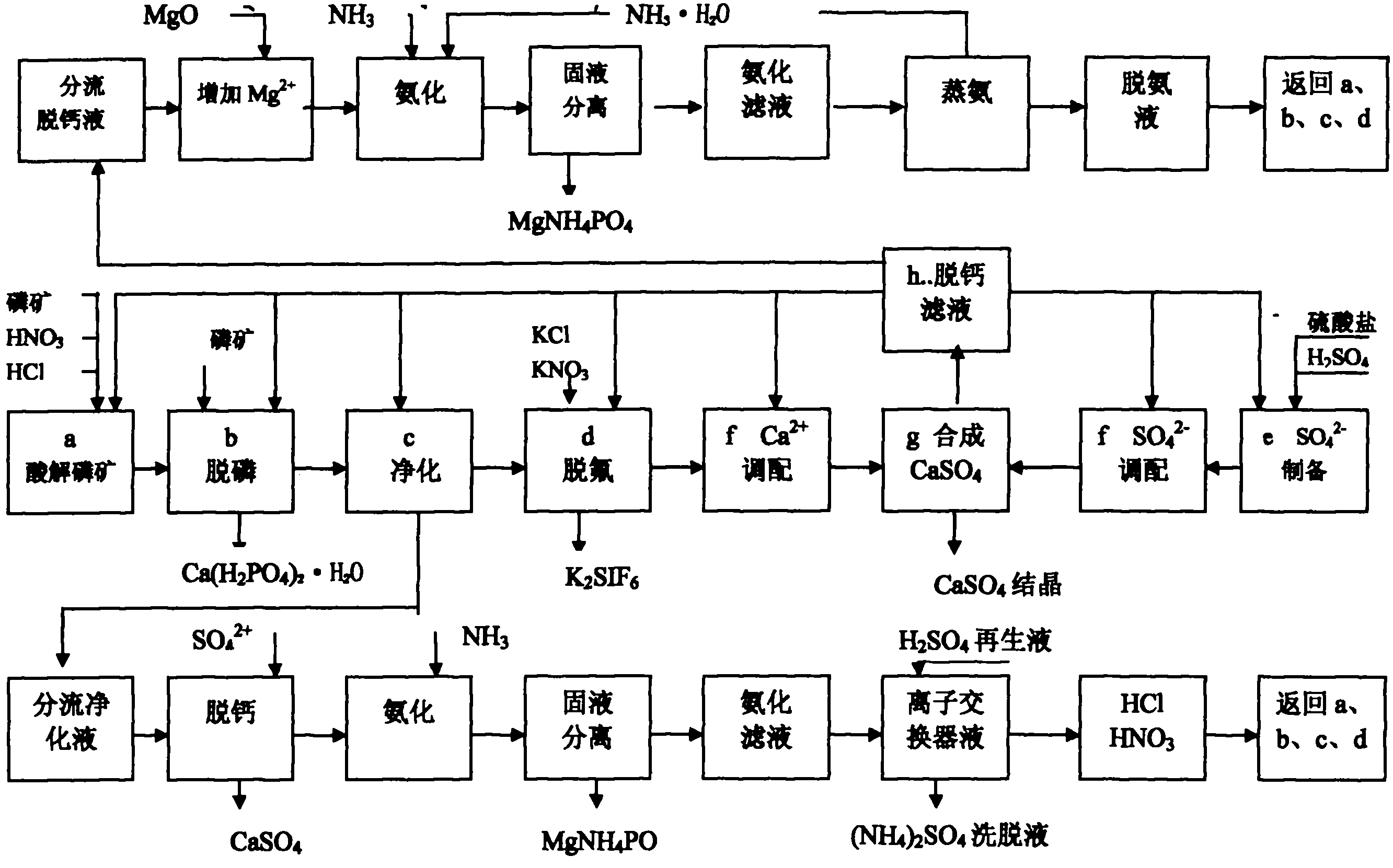

Method used

Image

Examples

Embodiment 2

[0095] The beneficial effects of the present invention:

[0096] 1. The main idea of the present invention is to make full use of the chemical energy of acid and the advantages of current phosphide processing technology, no matter if HCl or HNO is used 3 , H 3 PO 4 , H 2 SO 4 Or mixed acid can decompose magnesium-containing phosphate rock into purer Ca(H) with high processing value and use value. 2 PO 4 ) 2 ·H 2 O crystals, calcium becomes high-purity industrial filler CaSO 4 Or calcium sulfate whiskers, fluorine becomes pure fluorosilicate, magnesium becomes magnesium ammonium phosphate, and the raw materials used for acid hydrolysis of phosphate rock are completely recycled. Under the premise of eradicating the "three wastes", the theoretical utilization rate of raw materials is 100%. An independent new process for acid hydrolysis of phosphate rock including high-magnesium phosphate rock.

[0097] 2. The focus of the present invention is to turn magnesium ions into controllable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com