Coking wastewater advanced treatment and evaporative crystallization zero discharge process

A technology for coking wastewater and evaporative crystallization, which is applied in the fields of oxidized water/sewage treatment, special compound water treatment, natural water treatment, etc. Reduce the risk of organic contamination, increase service life, and prolong the effect of regeneration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

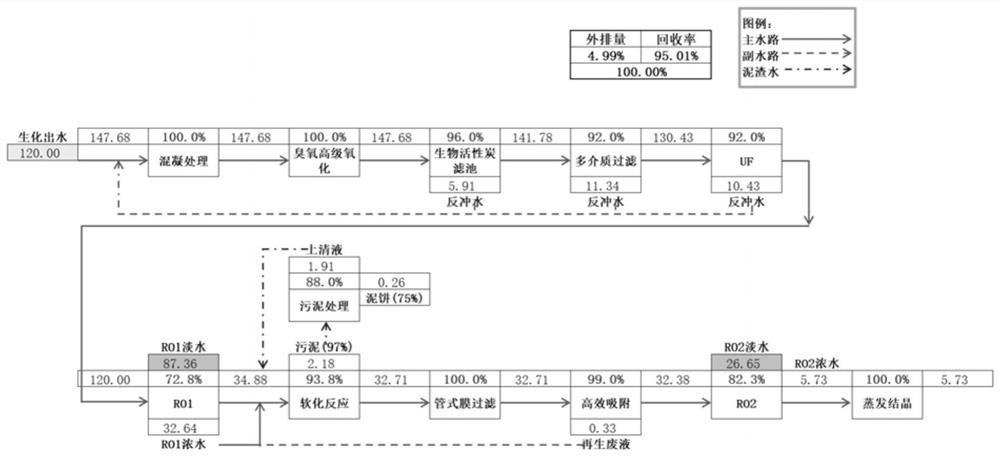

[0093] In this example, the biochemically treated coking wastewater of a certain coking plant is subjected to advanced treatment, with a water volume of 120m 3 / h, see Table 1 for influent water quality indicators.

[0094] Table 1 Influent water quality indicators

[0095] serial number project unit Influent water quality 1 pH - 6-9 2 COD mg / L 150 3 NH 3 -N

mg / L 5 4 Total Dissolved Solids (TDS) mg / L 3800 5 Conductivity μS / cm 5500 6 Total hardness (as CaCO 3 count)

mg / L 250 7 Total Alkalinity (as CaCO 3 count)

mg / L 250 8 Chloride mg / L 1300

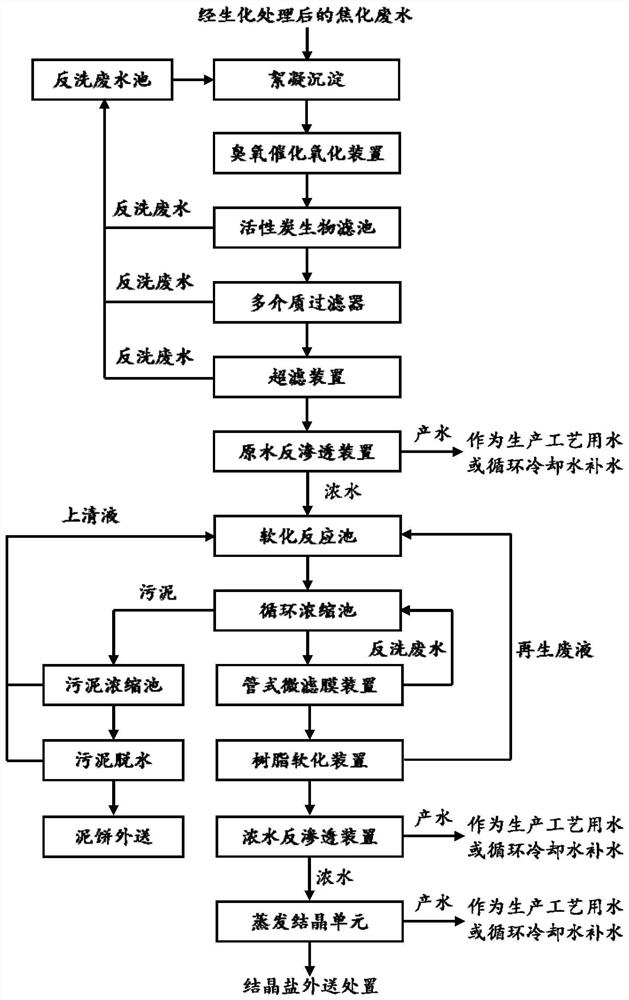

[0096] see figure 1 , the coking wastewater advanced treatment and evaporation crystallization zero-discharge process of this embodiment includes the following steps:

[0097] 1) Flocculation treatment

[0098] The coking wastewater after biochemical treatment is mixed with various subsequent backwash wastewater, and then enters the fl...

Embodiment 2

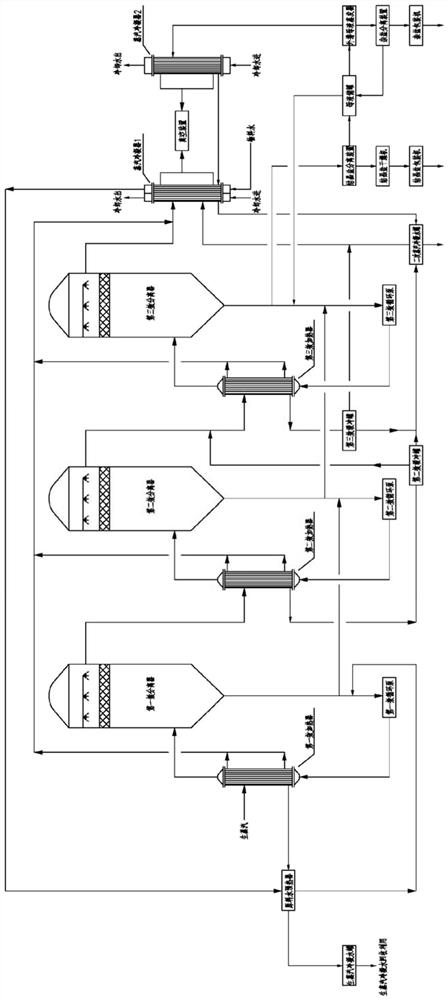

[0130] A coking plant coking wastewater biochemical effluent 160m 3 / h, circulating sewage 140m 3 / h, the circulating sewage is collected in front of the multimedia filter after chemical dehardening, and the influent water quality indicators are shown in Table 2.

[0131] Table 2 Influent water quality indicators

[0132] serial number project unit Biochemical effluent Circulating sewage 1 pH - 6-9 6-9 2 COD mg / L 200 40 3 NH 3 -N

mg / L 4 1 4 Total Dissolved Solids (TDS) mg / L 4600 2300 5 Conductivity μS / cm 6000 3000 6 Total hardness (as CaCO 3 count)

mg / L 350 800 7 Total Alkalinity (as CaCO 3 count)

mg / L 300 300 8 Chloride mg / L 1200 400

[0133] The coking wastewater advanced treatment and evaporation crystallization zero discharge process in this embodiment are generally the same as in Embodiment 1, mainly including the following steps (the same parts will not be re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

| Total alkalinity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com