Preparation method and application of Pd/modified bauxite catalyst

A bauxite and catalyst technology, applied in the field of nanomaterial catalysis, achieves the effects of low loading, obvious application value, and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

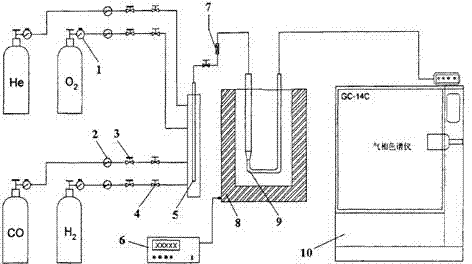

Method used

Image

Examples

Embodiment 1

[0028] The natural bauxite was heated at 130°C for 72 hours, dried at 80°C for 4 hours, and then roasted at 550°C for 4 hours to obtain a modified bauxite carrier with a high specific surface area; PdCl 2 Dissolved in 2 mol / L HCl solution to prepare H with a concentration of 0.03g / ml 2 PdCl 4 solution as an impregnation solution. At room temperature, measure 1.7ml H 2 PdCl 4 Solution, add deionized water to 4.2ml, measure 1.4ml H each time 2 PdCl 4 Solution, divided into three times, using equal volume impregnation method, impregnated 2g of modified bauxite carrier in H 2 PdCl 4 The solution was dried under an infrared lamp for 1 h and calcined at 450 °C for 2 h to prepare Pd / bauxite catalysts with palladium loadings of 1.5%.

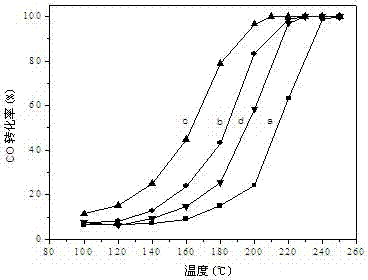

[0029] The mass fraction of Pd is the application of the Pd / bauxite catalyst of 1.5%. Get the above-mentioned Pd / bauxite catalyst 0.10g with modified bauxite as the carrier and put it into the bottom of the thick tube of the U-shaped sample tube ...

Embodiment 2

[0034] The natural bauxite was heated at 170°C for 48 hours, dried at 90°C for 4 hours, and then roasted at 550°C for 2 hours to obtain a modified bauxite carrier with a high specific surface area; PdCl 2 Dissolved in 2 mol / L HCl solution to prepare H with a concentration of 0.03g / ml 2 PdCl 4 solution as an impregnation solution. At room temperature, measure 0.2ml H 2 PdCl 4 Solution, add deionized water to 4.2ml, measure 1.4ml H each time 2 PdCl 4 Solution, three times using the equal volume impregnation method, the modified 2g bauxite carrier was impregnated in H 2 PdCl 4 solution, dried under an infrared lamp, and calcined at 450 °C for 2 h to prepare Pd / bauxite catalysts with palladium loadings of 0.2%.

[0035] The mass fraction of Pd is the application of the Pd / bauxite catalyst of 0.2%. Get the above-mentioned Pd / bauxite catalyst 0.10g with modified bauxite as the carrier and insert it into the bottom of the thick tube of the U-shaped sample tube plugged with qua...

Embodiment 3

[0040] The natural bauxite was heated at 150°C for 60 hours, dried at 110°C for 4 hours, and then roasted at 550°C for 3 hours to obtain a modified bauxite carrier with a high specific surface area; PdCl 2 Dissolved in 2 mol / L HCl solution to prepare H with a concentration of 0.03g / ml 2 PdCl 4 solution as an impregnation solution. At room temperature, measure 3.4ml H 2 PdCl 4 Solution, add deionized water to 4.2ml, measure 1.4ml H each time 2 PdCl 4 Solution, divided into three times, using equal volume impregnation method, impregnated 2g of modified bauxite carrier in H 2 PdCl 4 solution, dried under an infrared lamp, and calcined at 450 °C for 2 h to prepare Pd / bauxite catalysts with palladium loadings of 3.0%.

[0041] The mass fraction of Pd is the application of the Pd / bauxite catalyst of 3.0%. Get the above-mentioned Pd / bauxite catalyst 0.10g with modified bauxite as the carrier and put it into the bottom of the thick tube of the U-shaped sample tube plugged with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com