Complete set of equipment and method for separating high-temperature coal tar components via low-temperature rapid extraction method

A high-temperature coal tar and coal tar technology, which is applied in the direction of tar processing through selective solvent extraction and tar processing through distillation, can solve the problems of difficult processing, separation and treatment of coal tar pitch, and achieve easy automatic operation, Low equipment cost and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

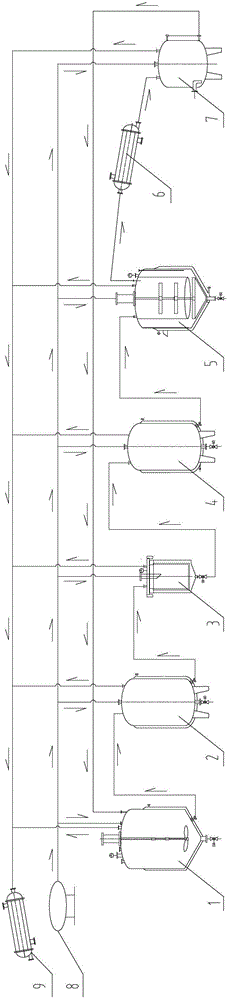

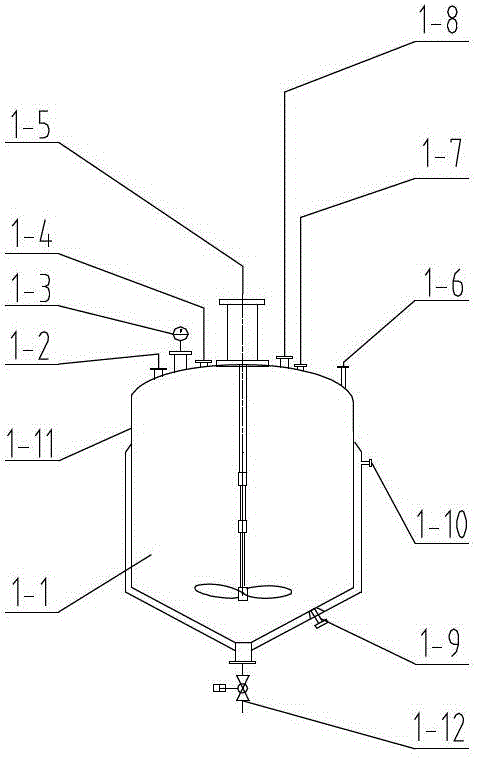

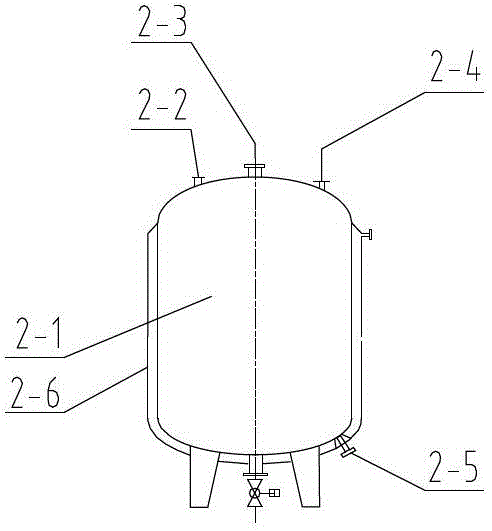

[0051] Embodiment 1: Separation of high-temperature coal tar components includes a complete set of equipment and methods; the complete set of equipment includes two kettles and four tanks, which are respectively composed of a coal tar extraction kettle, a light oil solution buffer tank, a filter tank, and a refined light oil Solution buffer tanks, stills and solvent storage tanks;

[0052] The solvent inlet 1-4 on the upper right side of the coal tar extraction kettle 1-1 is connected to the pipeline of the solvent outlet 7-5 on the lower right part of the solvent tank 7-3; the lower right side of the coal tar extraction kettle 1-1 The light oil solution outlet 1-9 is connected to the pipeline of the feed inlet 2-2 on the left top of the light oil solution buffer tank 2-1; the outlet 2-5 on the right bottom of the light oil solution buffer tank 2-1 is connected to The pipeline of the light oil solution inlet 3-1 on the top cover of the filter tank 3-5 is connected; the ref...

Embodiment 2

[0080] Embodiment 2: the equipment scheme is the same as implementation 1. The specific method process is as follows:

[0081] 1. The process of extracting coal tar and obtaining heavy pitch

[0082] Described concrete method process is as follows:

[0083] Step 1: According to the volume ratio of 1:4, inject the high-temperature coal tar raw material and the extraction solvent into the coal tar from the coal tar feed port 1-4 and the solvent feed port 1-6 on the top cover of the coal tar extraction kettle 1-1 respectively In the extraction kettle 1-1, and keep the total volume of the material to the 1 / 2 height range of the coal tar extraction kettle 1-1.

[0084] Step 2: Open the valves of steam heating coil outlet 1-10 and steam heating coil inlet 1-11, control and maintain the temperature in the kettle at 60 o C±5 o In the temperature range of C, open the magnetic stirring paddle 5 and continue to stir for 4 hours afterwards, and open the valves of the first tail gas ...

Embodiment 3

[0100] Embodiment 3: the equipment scheme is the same as implementation 1. The specific method process is as follows:

[0101] 1. The process of extracting coal tar and obtaining heavy pitch

[0102] Step 1: According to the volume ratio of 1:6, inject the high-temperature coal tar raw material and the extraction solvent into the coal tar from the coal tar feed port 1-4 and the solvent feed port 1-6 on the upper cover of the coal tar extraction kettle 1-1 respectively Extraction kettle 1-1, and keep the total volume of materials to 2 / 3 of the height range of coal tar extraction kettle 1-1.

[0103] Step 2: Open the valves of steam heating coil outlet 1-10 and steam heating coil inlet 1-11, control and maintain the temperature in the kettle at 60 o C±5 o In the temperature range of C, open the magnetic stirring paddle 5 and continue to stir for 1 hour afterwards, and open the valves of the first tail gas release port 1-8 and the light oil solution discharge port 1-9 after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com