High-salt waste water zero emission and salt separation processing method and device

A technology for high-salt wastewater and treatment methods, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Separation of polluted salt components using flocculants, efficient treatment of wastewater, etc., to achieve the effect of reducing investment costs and space, improving effluent quality, and reducing chemical dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

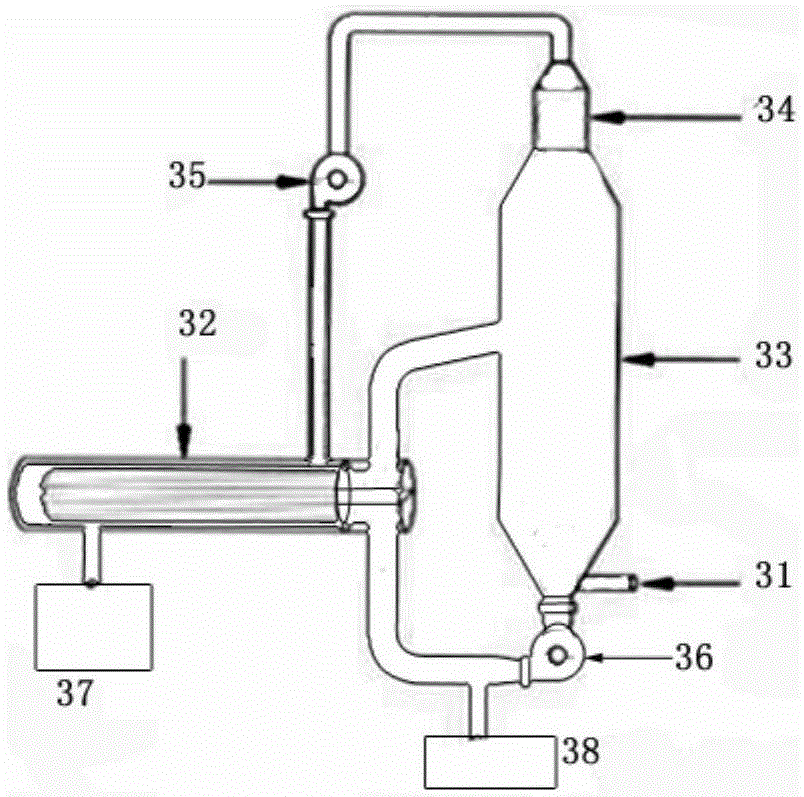

[0142] Embodiment 1 A treatment method for high-salt wastewater with zero discharge and salt separation, comprising the following steps: S1 wastewater pretreatment; S2 wastewater reduction and concentration; S3 crystallization.

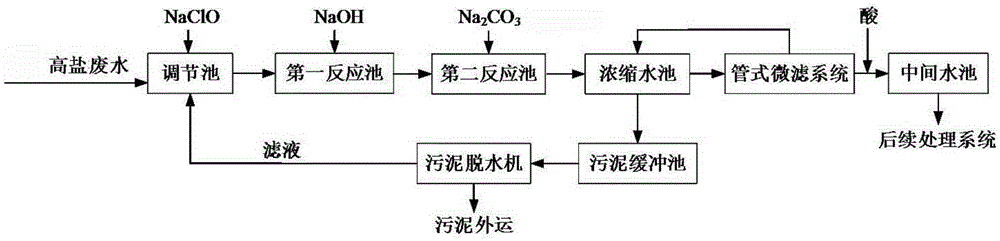

[0143] Step S1: The wastewater pretreatment process is a chemical softening-tubular microfiltration treatment process, including the following steps:

[0144] S1-1 High-salt wastewater first enters the regulating tank, and sodium hypochlorite is added to the regulating tank; the effluent from the regulating tank enters the first reaction tank, and sodium hydroxide is added to the first reaction tank for reaction; the effluent from the first reaction tank enters the second reaction tank, and the second reaction Add sodium carbonate solution to react in the pool;

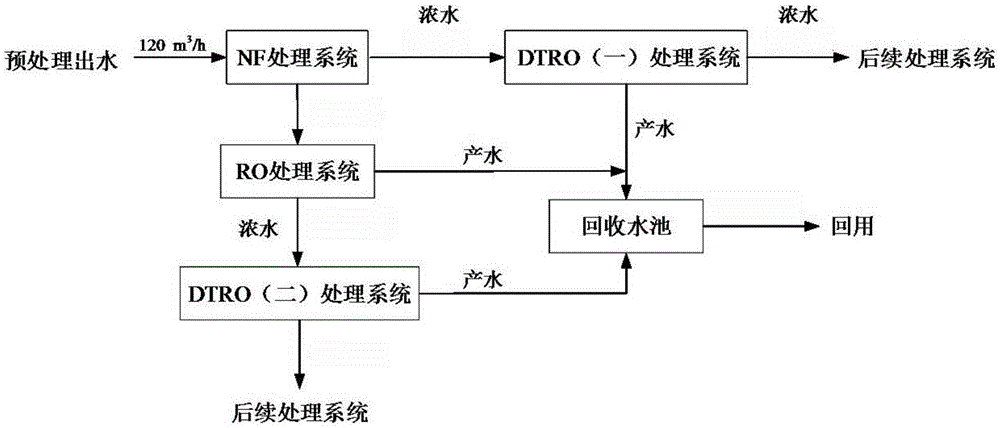

[0145] S1-2 After the reaction in the second reaction tank, the effluent overflows into the concentration tank, and the concentration tank and the tubular microfiltration system carry out wat...

Embodiment 2

[0149] A treatment method for high-salt wastewater with zero discharge and salt separation, comprising the following steps: S1 wastewater pretreatment; S2 wastewater reduction and concentration; S3 crystallization.

[0150] Step S1: The wastewater pretreatment process is a chemical softening-tubular microfiltration treatment process, including the following steps:

[0151] S1-1 High-salt wastewater first enters the regulating tank, and sodium hypochlorite is added to the regulating tank; the effluent from the regulating tank enters the first reaction tank, and sodium hydroxide is added to the first reaction tank for reaction; the effluent from the first reaction tank enters the second reaction tank, and the second reaction Add sodium carbonate solution to react in the pool;

[0152] S1-2 After the reaction in the second reaction tank, the effluent overflows into the concentration tank, and the concentration tank and the tubular microfiltration system carry out water circulatio...

Embodiment 3

[0157] A treatment method for high-salt wastewater with zero discharge and salt separation, comprising the following steps: S1 wastewater pretreatment; S2 wastewater reduction and concentration; S3 crystallization.

[0158] Step S1: The wastewater pretreatment process is a chemical softening-tubular microfiltration treatment process, including the following steps:

[0159] S1-1 High-salt wastewater first enters the regulating tank, and sodium hypochlorite is added to the regulating tank; the effluent from the regulating tank enters the first reaction tank, and sodium hydroxide is added to the first reaction tank for reaction; the effluent from the first reaction tank enters the second reaction tank, and the second reaction Add sodium carbonate solution to react in the pool;

[0160] S1-2 After the reaction in the second reaction tank, the effluent overflows into the concentration tank, and the concentration tank and the tubular microfiltration system carry out water circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com