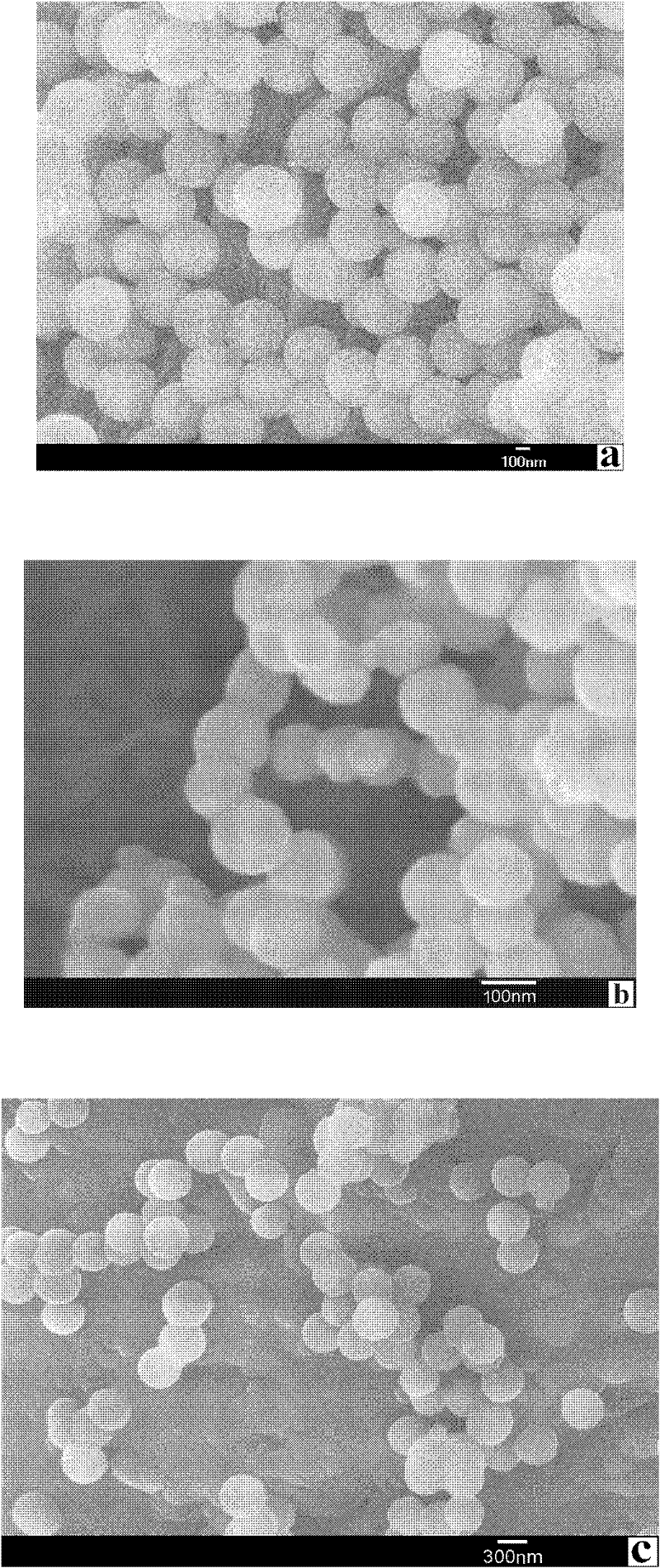

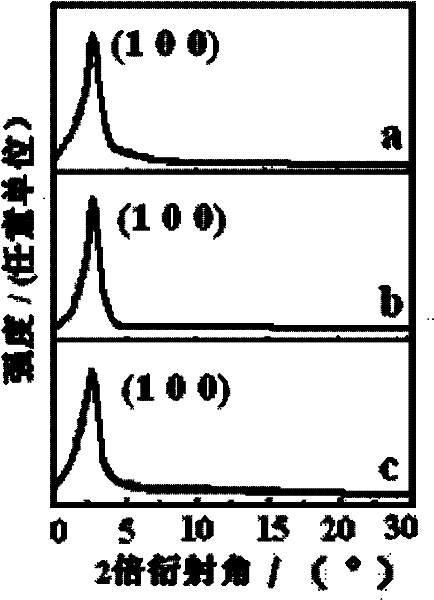

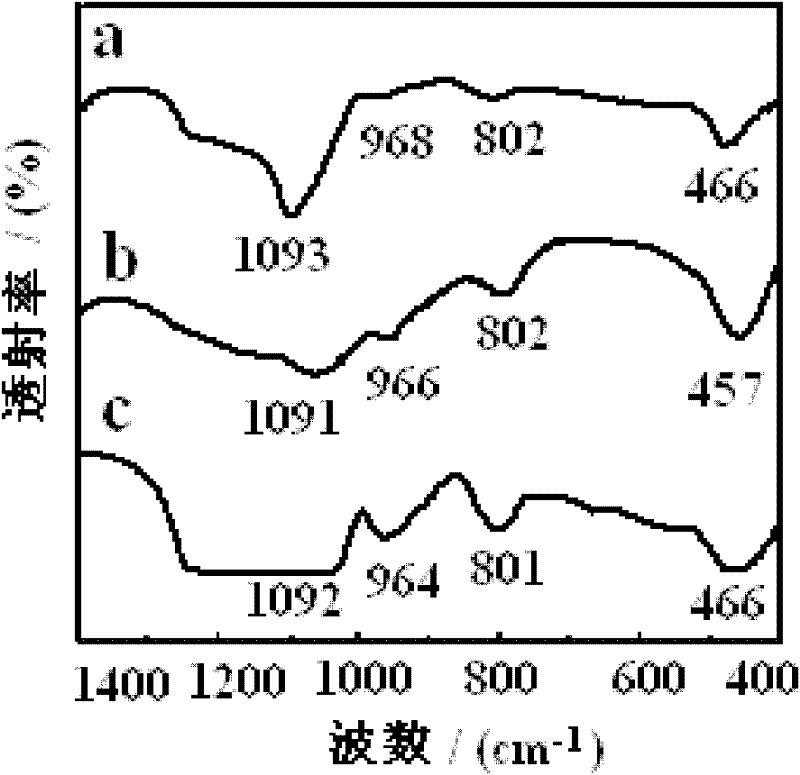

Spherical MCM-41 molecular sieve with particle size more than 400 nanometers, and synthesis method for the same

A technology of MCM-41, synthesis method, applied in nanotechnology, crystalline aluminosilicate zeolite, etc., can solve the problems of uneven size, irregular molecular sieve particle shape, harsh process conditions, etc., to achieve thermal stability and hydrothermal Improved stability, relaxed process conditions and uniform energy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Dissolve 1.8 g of dedecyltrimethylammonium bromide in 480 ml of distilled water, and stir at a temperature of 80°C. After the dedecyltrimethylammonium bromide is completely dissolved, add the concentration of 2mol L -1 3.5ml of aqueous sodium hydroxide solution, kept at 80°C and stirred until the solution was uniform, to obtain an alkaline aqueous solution of dodecyltrimethylammonium bromide. Take 5ml of tetraethyl orthosilicate, slowly drop it into the alkaline aqueous solution of dedecyltrimethylammonium bromide, the solution becomes turbid, stir vigorously at 80°C for 2 hours to synthesize molecular sieves, and obtain a synthetic solution. Then filter the synthetic solution with neutral filter paper, filter out the solid powder, and keep the filtrate. The solid powder was washed with distilled water, dried at room temperature, and then the dried solid powder was calcined in a muffle furnace for 4 hours at a calcination temperature of 500°C to completely remove the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com