Diffusion technique of crystal-silicon efficient high-sheet-resistance battery piece

A diffusion process and high square resistance technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult control of square resistance uniformity, high concentration of dead layer on the front surface, low VOC, etc., and achieve a large room for process adjustment, ISC and VOC improve and reduce the effect of process running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

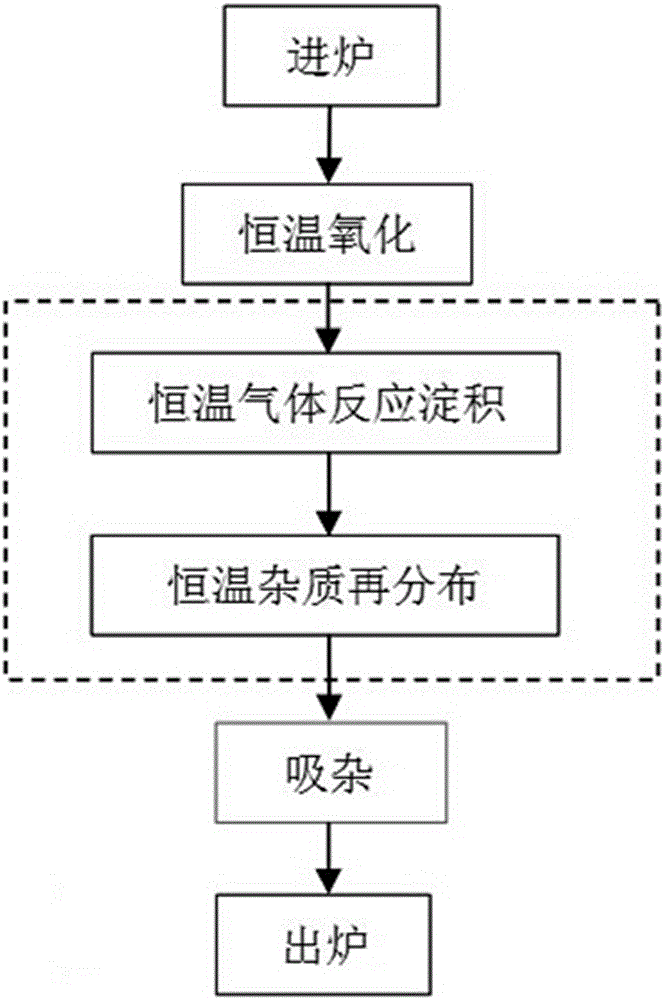

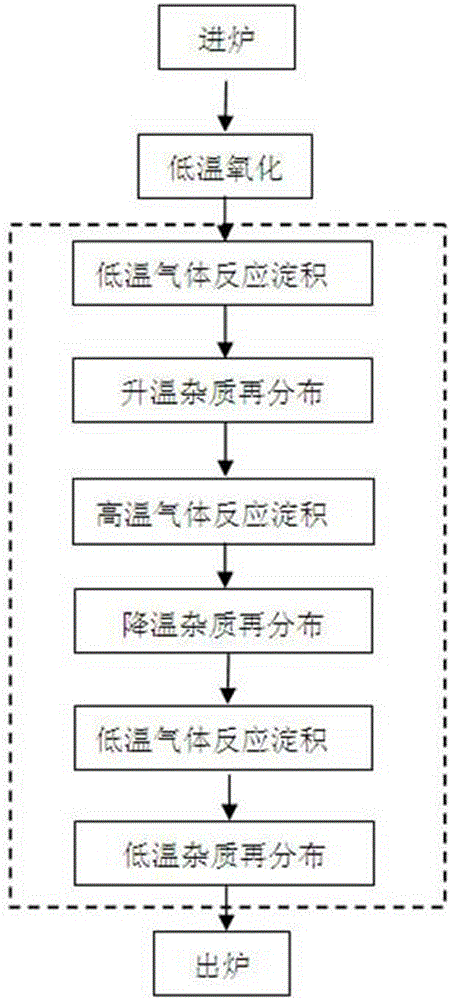

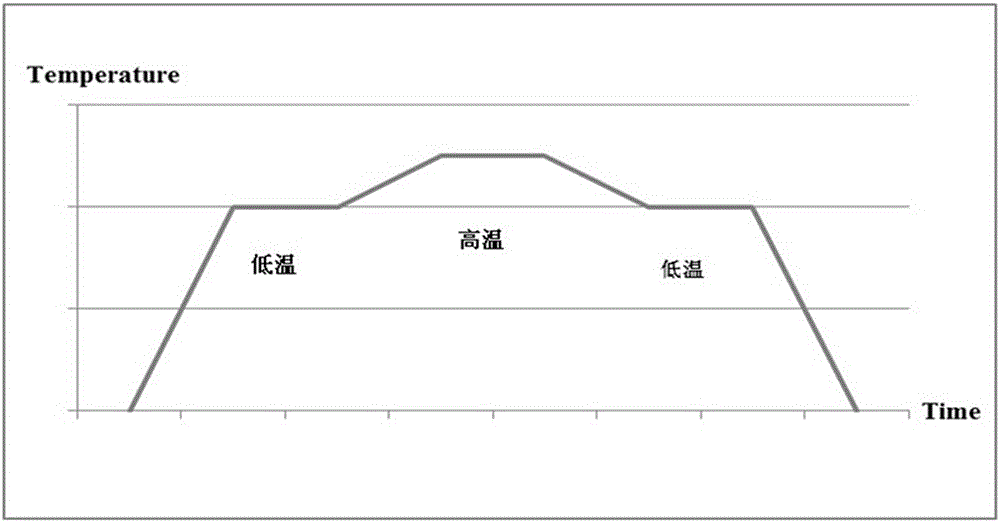

[0033] Such as figure 2 , 3 As shown, the diffusion process of the crystalline silicon high-efficiency high-resistivity battery sheet of the present invention comprises the following steps:

[0034] (1) Into the furnace; the process of entering the furnace is: put the silicon wafer into the diffusion furnace, maintain the temperature at 750-800°C, and feed nitrogen gas with a flow rate of 6000-8000sccm for 10-20min;

[0035] (2) Low-temperature oxidation, that is, to perform low-temperature oxidation on the silicon wafers after entering the furnace; the process is: maintain the temperature at 750-800°C, feed nitrogen with a nitrogen flow rate of 6000-8000 sccm, feed dry oxygen, dry oxygen The flow rate is 1000-2000sccm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com