Fabrication method of metastable high magnesium mgzno solid solution alloy film by laser ablation

A solid solution alloy and laser ablation technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve problems such as difficult film formation, difficult establishment of thermodynamic phase balance, and difficulty in preparation of ceramic targets, achieving The effect of relaxed process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] 3. Preparation of gel film

[0014] The substrate is adsorbed on the spin coating table of the spin coating machine, and the geometric center of the substrate is located on the axis of the spin coating table; the sol solution is dripped onto the substrate with a glue head dropper; The table rotates at a speed of 500 rpm for 10 sec, and then rotates at a speed of 3000 rpm for 30 sec to form a layer of wet gel film on the substrate to obtain a wet film substrate; heat the wet film substrate at 50°C for 5 to 10 minutes , and then dried at 180° C. and 150° C. for 5 to 10 minutes successively in a constant temperature drying oven to fully volatilize the solvent in the wet gel film to obtain a gel film.

[0015] To thicken the gel film, repeat this step several times. However, as the number of repetitions increases, so do the defects in the gel film.

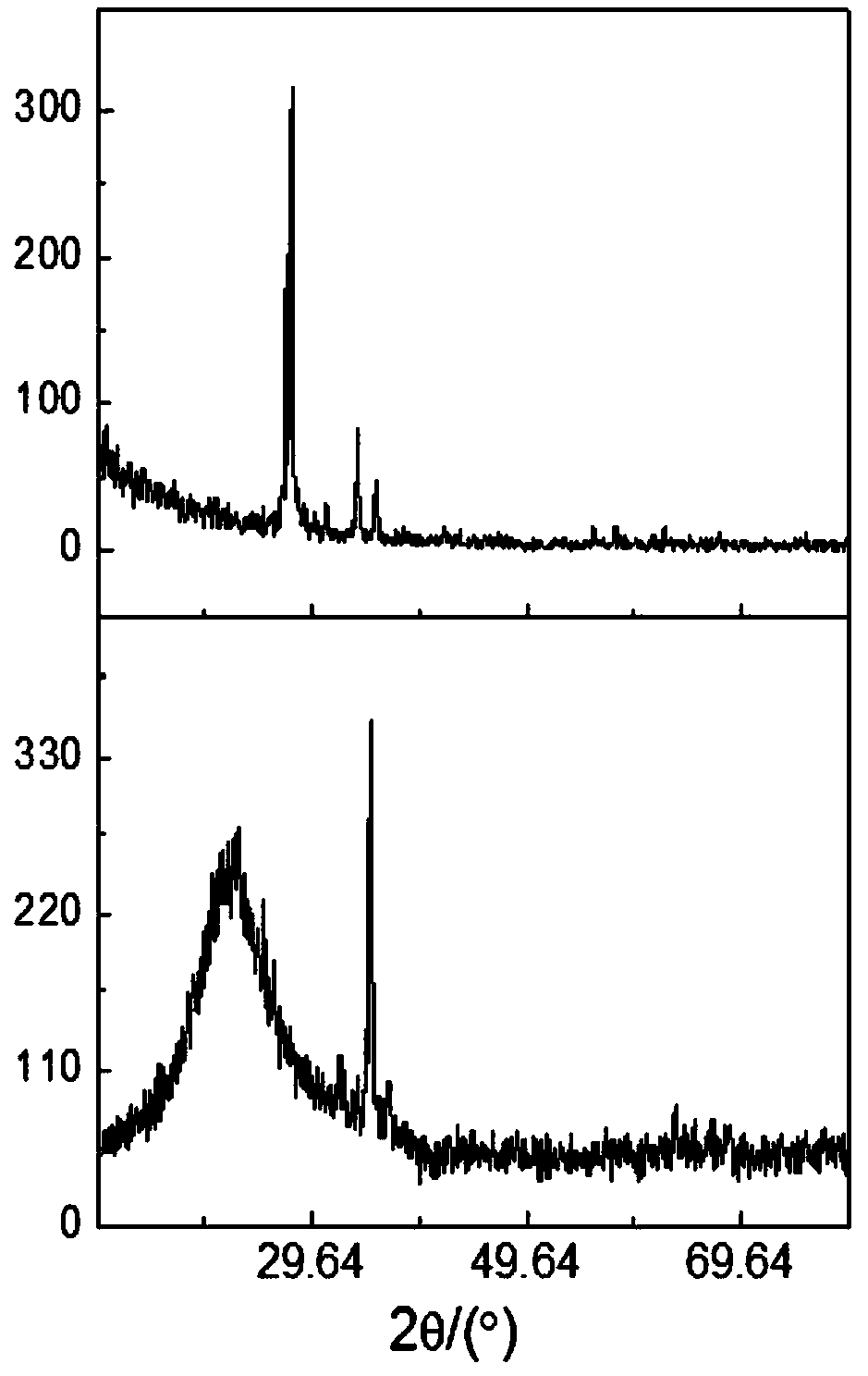

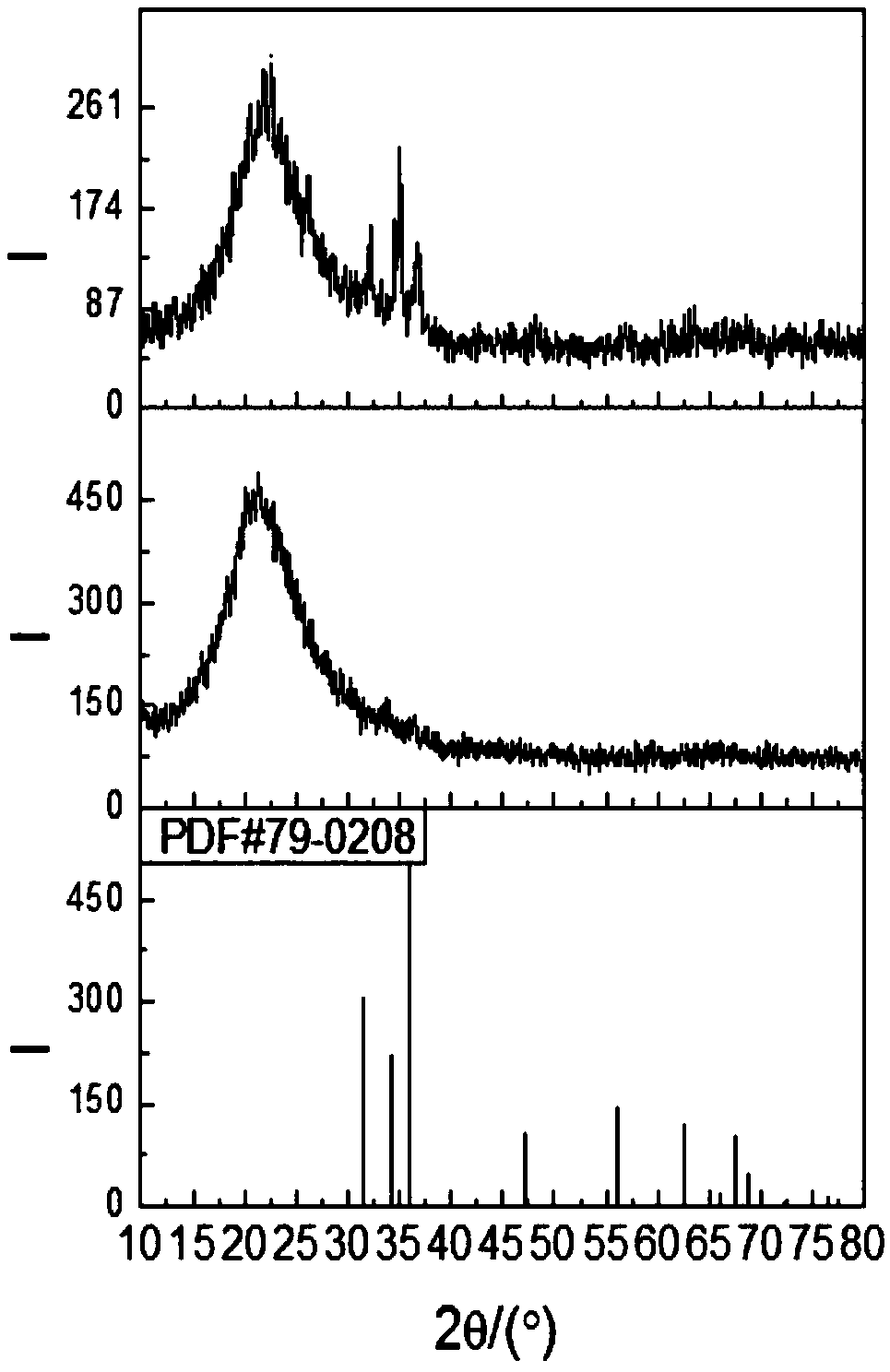

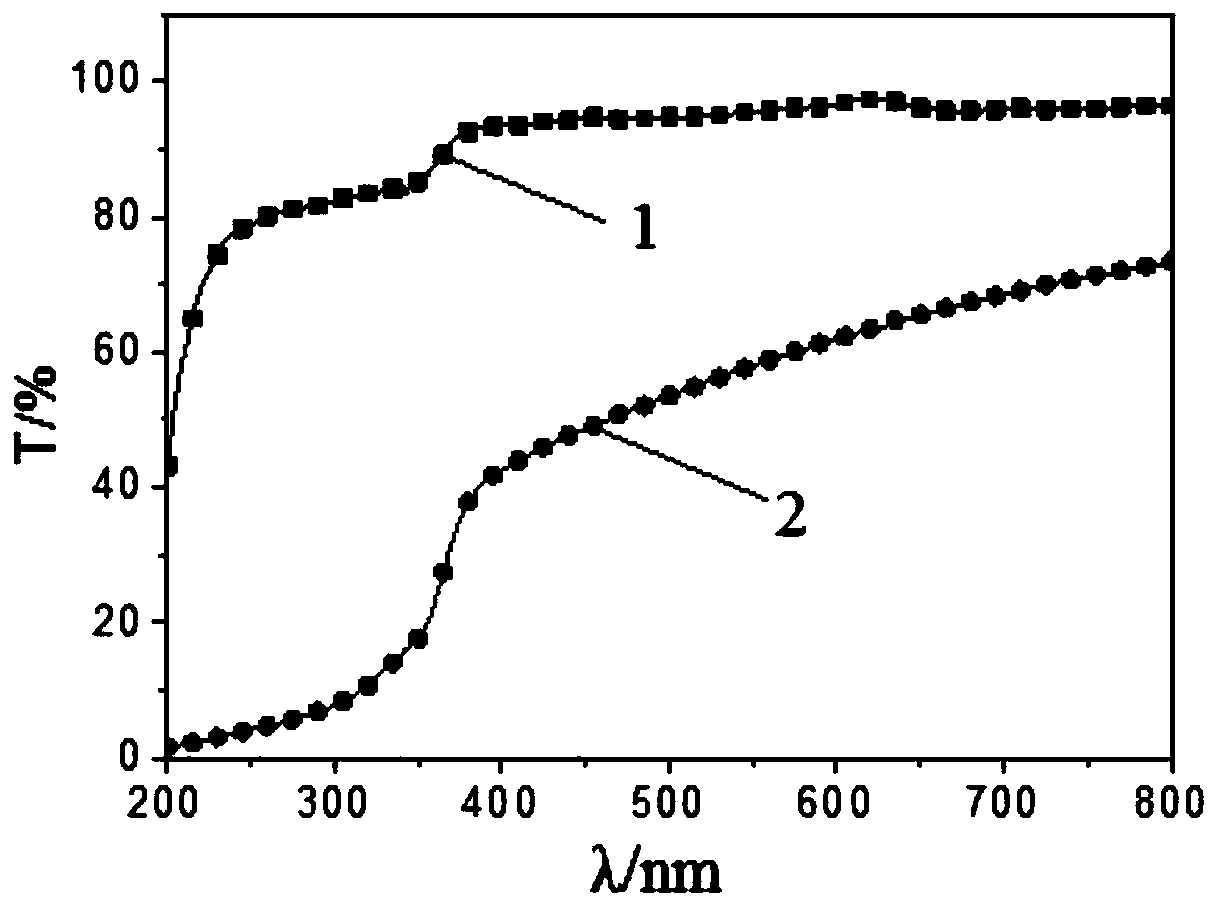

[0016] 4. Fabrication of Metastable High Magnesium MgZnO Solid Solution Alloy Thin Film

[0017] The gel film is ablated b...

example 1

[0019] Example 1: select a silicon wafer as the substrate; clean the substrate in an ultrasonic cleaner for 10 minutes with a degreasing agent; then clean the substrate in an ultrasonic cleaner with hydrochloric acid for 10 minutes; then use absolute ethanol in an ultrasonic cleaner The substrate was cleaned for 10 minutes; finally, the substrate was repeatedly cleaned in an ultrasonic cleaner with deionized water; and the substrate was dried in a drying oven. The sol solution was prepared with A.R. pure zinc acetate, magnesium acetate and ethanol as raw materials. Determine Mg x Zn 1-x The value of x in O is 0.75, and the molar ratio of zinc acetate to magnesium acetate is 1:4. Dissolve zinc acetate and magnesium acetate in 15ml of ethanol to prepare Mg 2+ , Zn 2+ A solution with a total concentration of 0.8mol / L was added with Mg 2+ and Zn 2+ Ethanolamine was used as a complexing agent in an equal amount, and after stirring at 60° C. for 1.5 h, a transparent homogeneous...

example 2

[0020] Example 2: select a quartz glass sheet as the substrate; clean the substrate in an ultrasonic cleaner for 10 minutes with degreasing agent; then clean the substrate in an ultrasonic cleaner with hydrochloric acid for 10 minutes; then use absolute ethanol in an ultrasonic cleaner Clean the substrate in medium for 10 min; finally use deionized water to clean the substrate repeatedly in an ultrasonic cleaner; dry the substrate in a drying oven. The sol solution was prepared with A.R. pure zinc acetate, magnesium acetate and ethylene glycol methyl ether as raw materials. Determine Mg x Zn 1-x The value of x in O is 0.5, and the molar ratio of zinc acetate to magnesium acetate is 1:1. Dissolve zinc acetate and magnesium acetate in 20ml of ethylene glycol methyl ether to prepare Mg 2+ , Zn 2+ A solution with a total concentration of 1.0mol / L was added with Mg 2+ and Zn 2+The same amount of ethanolamine was used as a complexing agent, and after stirring for 2 hours at a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com