A kind of synthetic method of phthalonitrile

A technology of phthalonitrile and synthesis method, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., and can solve no reports on pilot scale and industrialization , there are not many research reports, and the weight yield is high, which is conducive to large-scale production, a wide range of raw material sources, and good reaction selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

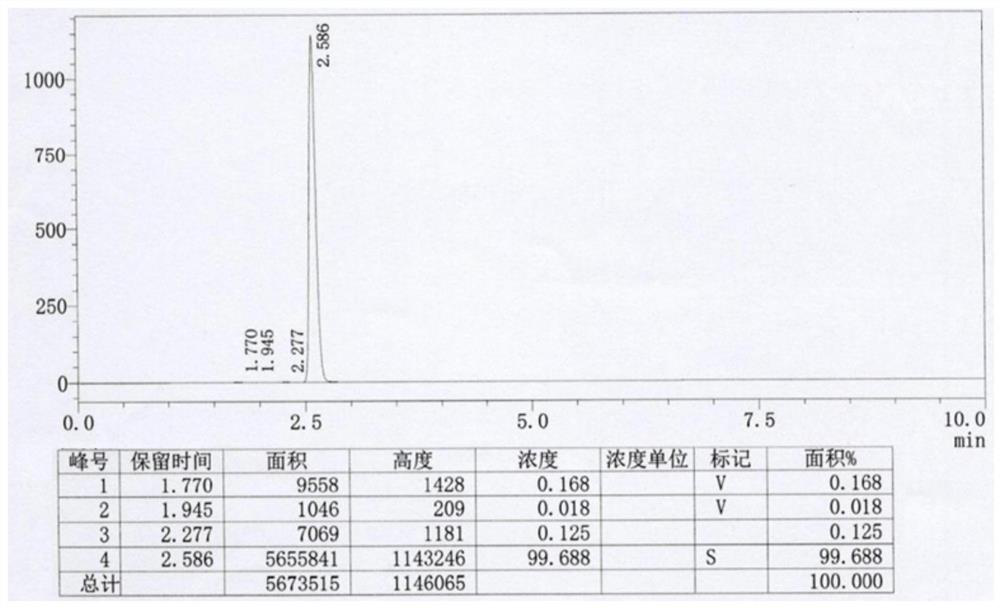

Image

Examples

preparation example Construction

[0033] The synthesis method of phthalonitrile provided by the present invention uses o-xylene as a raw material to carry out hierarchical catalytic synthesis, which specifically includes the following steps.

[0034] Step 1, mixing o-xylene, ammonia and air to carry out a first-order catalytic reaction to obtain a mixed intermediate product.

[0035] In the present invention, the ortho-xylene is mixed with decompressed quantitative ammonia and air after being passed through a heat-retaining metering pump to form a mixed gas, and then enters a primary catalytic bed for a primary catalytic reaction to obtain a mixed intermediate product.

[0036] The first-stage catalysis is carried out in the presence of catalyst I, and the catalyst I is a V-Cr-Mo-M catalyst, wherein V is vanadium, Cr is chromium, Mo is molybdenum; M is an alkali metal element , selected from one or more of Li, Na, K, Rb and Cs, preferably one or more of Li, Rb and Cs, more preferably Li and / or Cs, such as Cs. ...

Embodiment 1

[0083] Slowly dissolve 10.0g of vanadium pentoxide in 200g of oxalic acid aqueous solution containing 30g, add 3.8g of chromium trioxide at 85°C, and after it dissolves, add 4.5g of ammonium orthomolybdate ((NH 4 ) 2 MoO 4 ) and 2.6 g cesium sulfate, stirred for 2 hours. The above solution was added to 100 g of silica gel with a particle size of 80-120 mesh. The silica gel was preheated to about 85°C in advance, stirred evenly, and allowed to stand at 20-30°C for 16 hours to obtain a catalyst precursor. Take it out and place it in a muffle furnace to gradually raise the temperature to 600°C and keep it warm for 12 hours. After cooling to room temperature, the catalyst I is obtained and bottled for future use. In the catalyst I, V:Cr:Mo:Cs:=1:0.35:0.21:0.13. Physical adsorption BET test was carried out on catalyst Ⅰ, and its BET specific surface area was 361.1m 2 / g.

Embodiment 2

[0085] Slowly dissolve 5.0g of vanadium pentoxide and 21.5g of phosphoric acid solution with a mass fraction of 85% in 100g of aqueous solution containing 40g of oxalic acid, and then add 2.5g of chromium trioxide and 2.0g of nickel chloride at 80°C, and wait for them to dissolve After that, add 3.0g ammonium orthomolybdate ((NH 4 ) 2 MoO 4 ) and 1.5g of cesium sulfate, stirred for 1 hour, the above solution was added to 50g of silica gel with a particle size of 80-120 mesh, the silica gel was preheated to 95°C in advance, stirred evenly, and stood at 20-30°C for 20 hours. Take it out and place it in a muffle furnace and gradually raise the temperature to 650°C, keep it warm for 12 hours, and after cooling to room temperature, the catalyst II is obtained, which is bottled for later use. V:Cr:P:Ni:Mo:Cs:=1:0.45:3.39:0.28:0.28:0.15 in catalyst II. Physical adsorption BET test was carried out on Catalyst II, and its BET specific surface area was 399.2m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com