Production technique for preparing architectural ornament phosphorus slag cast stone by employing high-temperature phosphorus slag liquid

A technology for building decoration and phosphorus slag, which is applied in the field of building decoration, can solve the problems of high production cost, high energy consumption for heating and melting, inability to utilize the thermal energy of high-temperature phosphorus slag liquid, etc., and achieves the effect of reducing production cost and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

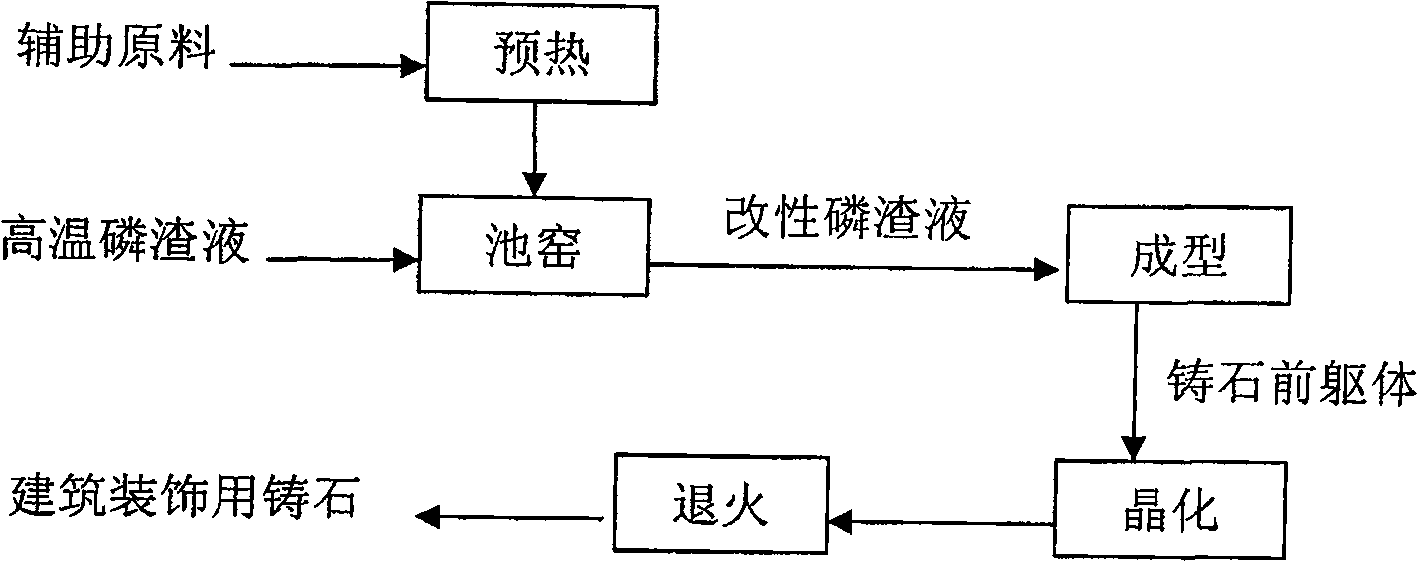

[0029] Such as figure 1 Shown, utilize high-temperature phosphorus slag liquid to prepare the production technology of phosphorus slag cast stone for building decoration, it comprises the following steps:

[0030] (1) Preparation and preheating of auxiliary raw materials: use quartz sand and kaolin as auxiliary raw materials, weigh and mix the quartz sand and kaolin with a particle size of less than 0.5mm in a mass ratio of 22:8, and then put them into the kiln. Heat to 1400°C to obtain the preheated auxiliary raw materials for later use;

[0031] (2) Hot ingredients: the high-temperature phosphorus slag liquid discharged from the phosphorus smelting electric furnace flows into the pool kiln through the liquid flow tank, and the preheated auxiliary raw materials obtained in step (1) are synchronously put into the pool kiln, wherein the phosphorus slag liquid The mass ratio with auxiliary raw materials is 70:30;

[0032] (3) Mixed melting: The mixed melting temperature of phosp...

Embodiment 2

[0036] A production process for preparing phosphorous slag cast stone for architectural decoration by utilizing high-temperature phosphorus slag liquid, it comprises the following steps:

[0037] (1) Preparation and preheating of auxiliary raw materials: use quartz sand and kaolin as auxiliary raw materials, weigh and mix the quartz sand and kaolin with a particle size of less than 0.5mm in a mass ratio of 25:10, and then put them into the kiln. Heat to 1400°C to obtain the preheated auxiliary raw materials for later use;

[0038] (2) Hot ingredients: the high-temperature phosphorus slag liquid discharged from the phosphorus smelting electric furnace flows into the pool kiln through the liquid flow tank, and the preheated auxiliary raw materials obtained in step (1) are synchronously put into the pool kiln, wherein the phosphorus slag liquid The mass ratio to auxiliary raw materials is 65:35;

[0039] (3) Mixed melting: The mixed melting temperature of phosphorus slag liquid ...

Embodiment 3

[0043] A production process for preparing phosphorous slag cast stone for architectural decoration by utilizing high-temperature phosphorus slag liquid, it comprises the following steps:

[0044] (1) Preparation and preheating of auxiliary raw materials: use quartz sand and kaolin as auxiliary raw materials, weigh and mix the quartz sand and kaolin with a particle size of less than 0.5mm in a mass ratio of 20:5, and then put them into the kiln. Heat to 1400°C to obtain the preheated auxiliary raw materials for later use;

[0045] (2) Hot ingredients: the high-temperature phosphorus slag liquid discharged from the phosphorus smelting electric furnace flows into the pool kiln through the liquid flow tank, and the preheated auxiliary raw materials obtained in step (1) are synchronously put into the pool kiln, wherein the phosphorus slag liquid The mass ratio with auxiliary raw materials is 75:25;

[0046] (3) Mixed melting: The mixed melting temperature of phosphorus slag liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com