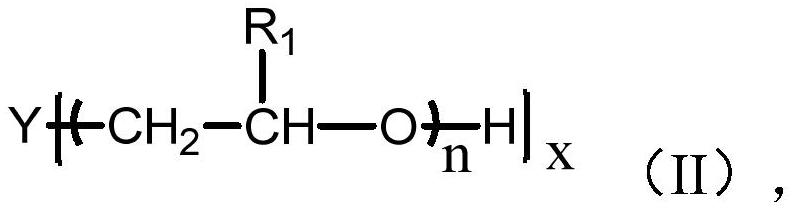

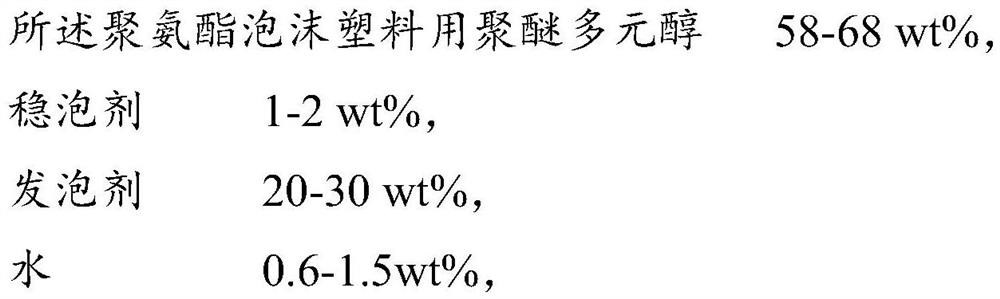

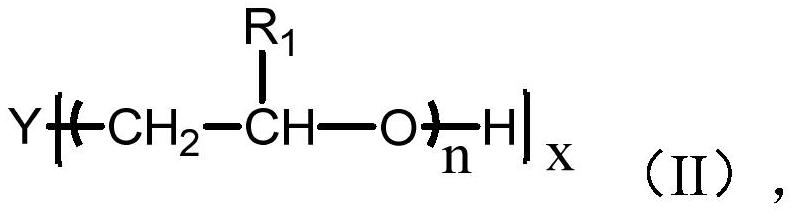

Polyether polyol for polyurethane foam plastic as well as preparation method and application of polyether polyol

A technology of polyether polyol and foam plastics, applied in the field of modified polyether polyol, can solve the problems of limited application range, poor solvent resistance, poor flame retardancy, etc., and achieve simple preparation process conditions and solvent resistance The effect of improving and relaxing process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Prepare polyether polyol 1# for polyurethane foam according to the following method:

[0086] Get 169g polyphosphoric acid and dissolve it in 169g dehydrated alcohol to prepare the dehydrated alcohol solution of polyphosphoric acid, then add dropwise to 300g polyether polyol in 3 batches In R2403 (to ensure that the molar ratio of the phosphorus atom of polyphosphoric acid to the hydroxyl group in the polyether polyol raw material is 1:2), the temperature of the reaction system is preheated to between 50-60°C, and the temperature of the system is stabilized at 55°C. Then the temperature was raised to 80° C., and the reaction was carried out for 4 hours. The product was extracted with ethyl acetate (the volume ratio of the extractant to the extracted liquid was 1:1), the organic phase was retained, and then the organic phase was washed with deionized water, extracted and washed 3 times until the aqueous phase was added dropwise to CaCl 2 There is no precipitation in th...

Embodiment 2

[0089] Prepare polyether polyol 2# for polyurethane foam according to the following method:

[0090] Get 169g polyphosphoric acid and dissolve in 135g methylene chloride to prepare the dehydrated alcohol solution of polyphosphoric acid, then add dropwise to 270g polyether polyol in 3 batches In R2403 (to ensure that the molar ratio of the phosphorus atom of polyphosphoric acid to the hydroxyl group in the polyether polyol raw material is 1:1.8), the temperature of the reaction system is preheated to between 50-60°C, and the temperature of the system is stabilized at 50°C. Then the temperature was raised to 75° C., and the reaction was carried out for 6 hours. The product was extracted with ethyl acetate (the volume ratio of the extractant to the extracted liquid was 1:1), the organic phase was retained, and then the organic phase was washed with deionized water, extracted and washed 3 times until the aqueous phase was added dropwise to CaCl 2 There is no precipitation in the...

Embodiment 3

[0093] Prepare polyether polyol 3# for polyurethane foam according to the following method:

[0094] Get 169g polyphosphoric acid and dissolve it in 152g dimethyl carbonate to prepare the absolute ethanol solution of polyphosphoric acid, then add dropwise to 330g polyether polyol in 3 batches In R2403 (to ensure that the molar ratio of the phosphorus atom of polyphosphoric acid to the hydroxyl group in the polyether polyol raw material is 1:2.2), the temperature of the reaction system is preheated to between 50-60°C, and the temperature of the system is stabilized at 60°C. Then the temperature was raised to 85° C., and the reaction was carried out for 2 hours. The product was extracted with ethyl acetate (the volume ratio of the extractant to the extracted liquid was 1:1), the organic phase was retained, and then the organic phase was washed with deionized water, extracted and washed 3 times until the aqueous phase was added dropwise to CaCl 2 There is no precipitation in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com