Iron-based amorphous-nanometer crystalline state magnetically soft alloy with high saturation magnetic induction density and application thereof

A technology of magnetic induction intensity and iron-based nanocrystals, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of easy volatilization, increase the production cost of alloys, and difficult to control the composition, so as to improve the saturation magnetic induction intensity and production process conditions The effect of loose, high saturation magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

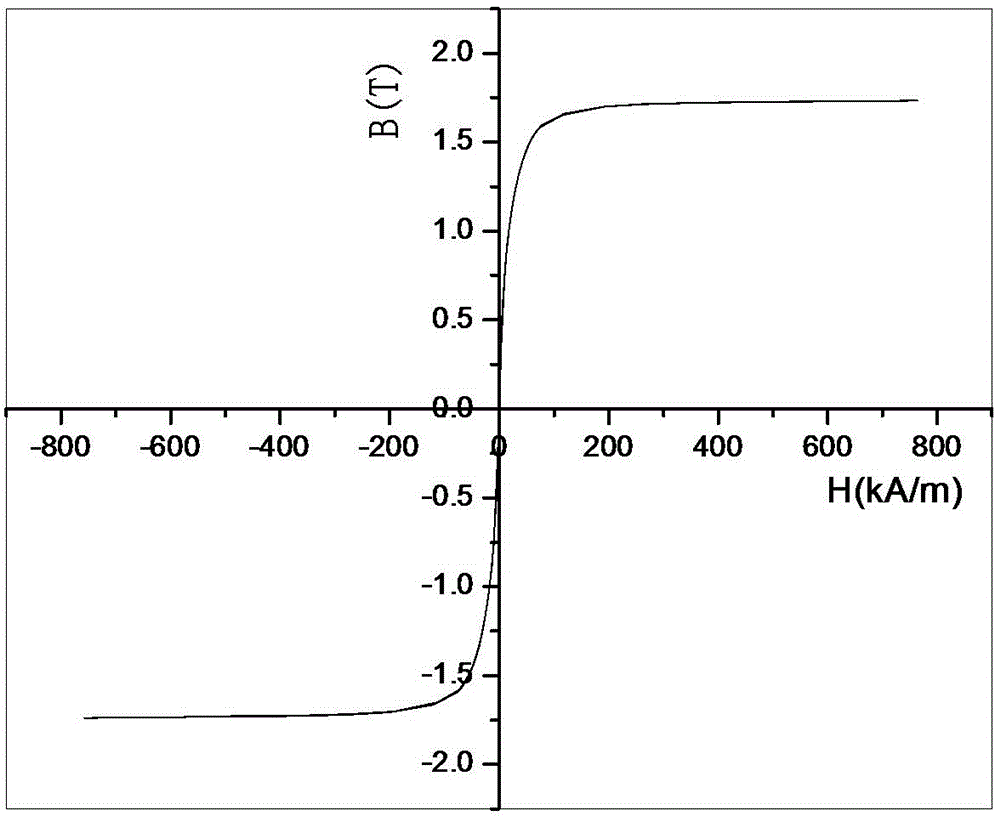

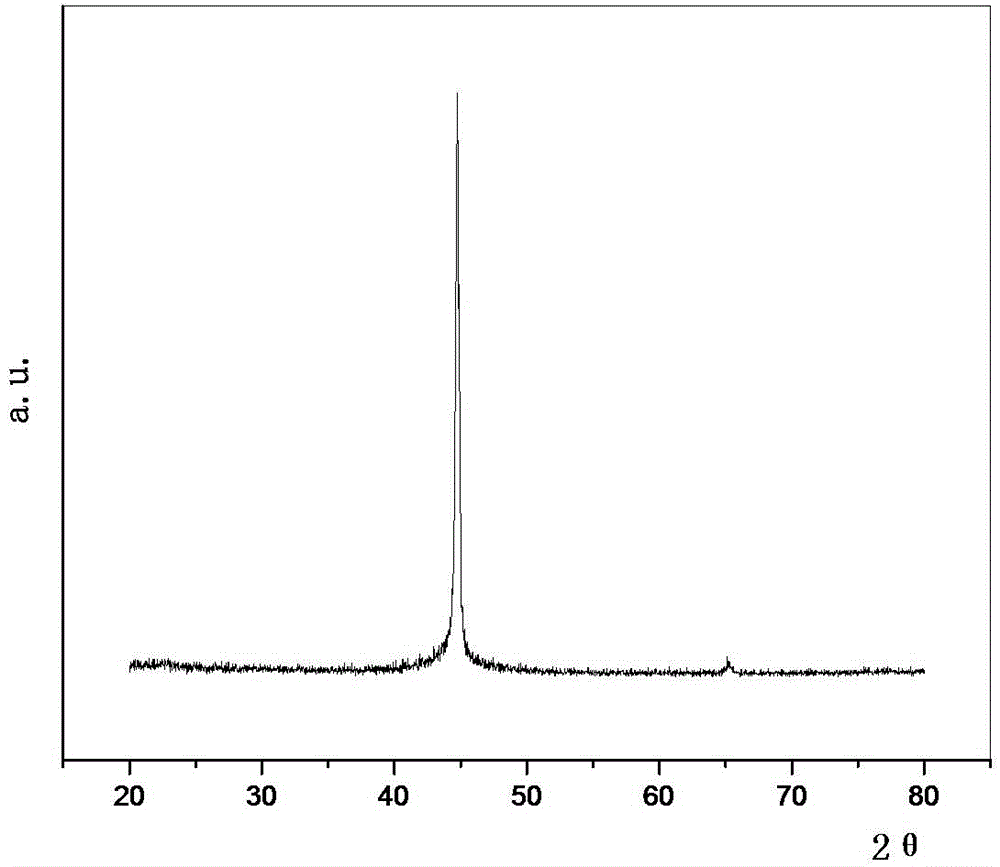

[0044] Example 1 : Fe 80 Si 7.65 B 10.35 al 2 For proportioning, the raw materials are placed in a non-consumable vacuum electric arc furnace, and the vacuum is evacuated to a vacuum degree of 5.0×10 -3 Mpa, high-purity argon gas is introduced with a purity of 99.99%. The raw materials are refined into master alloy ingots by arc melting using electromagnetic stirring, and the master alloy ingots are smelted repeatedly for 6 times to ensure the uniformity of the master alloy composition. Then put it into the positive air induction furnace for the second smelting, when the vacuum degree is 5.0×10 -3 At the same time, high-purity argon gas with a purity of 99.99% is filled, and the alloy is sprayed on the surface of the copper rod to make an iron-based amorphous-nanocrystalline ribbon. The main parameters for the preparation of amorphous-nanocrystalline strips are copper rod speed 25m / s, pressure difference 0.04Mpa, distance between the quartz tube and the surface of the wa...

Embodiment 2

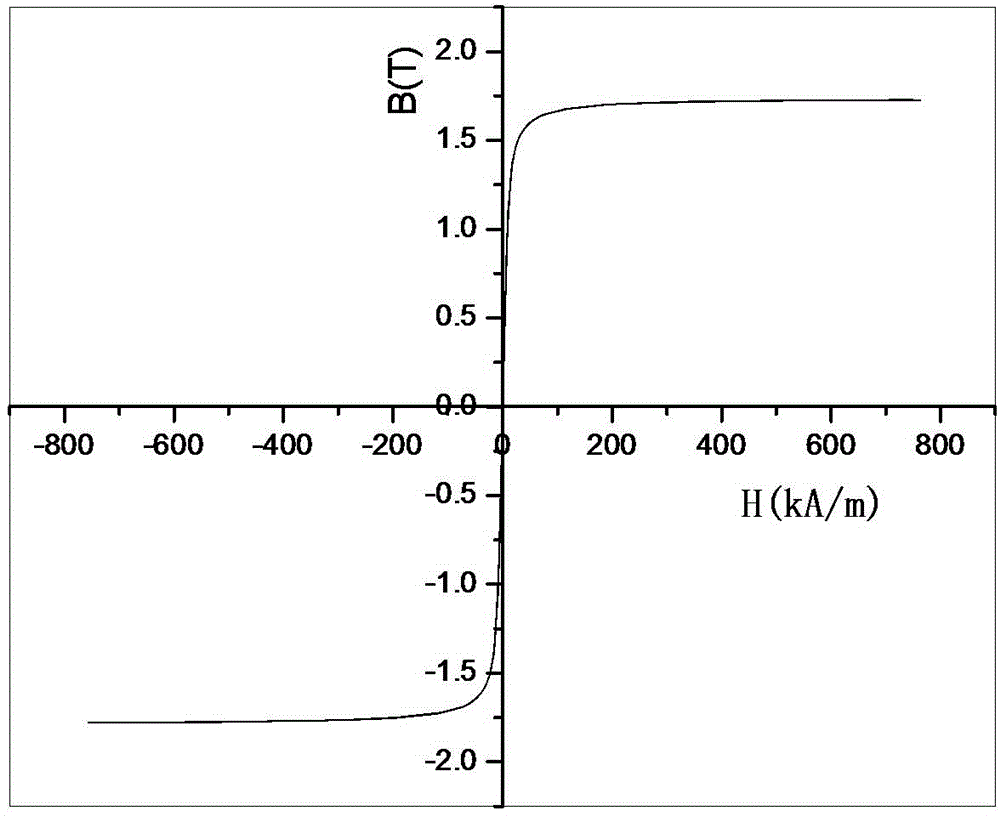

[0049] Example 2 : Fe 81 Si 6 B 11 al 2 For proportioning, the raw materials are placed in a non-consumable vacuum electric arc furnace, and the vacuum is evacuated to a vacuum degree of 5.0×10 -3 Mpa, high-purity argon gas is introduced, the purity is 99.99%, the master alloy ingot is smelted by electric arc melting with electromagnetic stirring, and the master alloy ingot is repeatedly smelted 6 times to ensure the uniformity of the master alloy composition. Then put it into the positive air induction furnace for the second smelting, when the vacuum degree is 5.0×10 -3 At the same time, high-purity argon gas with a purity of 99.99% is filled, and the alloy is sprayed on the surface of the copper rod to make an iron-based amorphous-nanocrystalline ribbon. The main parameters for the preparation of amorphous-nanocrystalline strips are copper rod speed 28m / s, pressure difference 0.03Mpa, distance between the quartz tube and the surface of the water-cooled copper rod is 0....

Embodiment 3

[0053] Example 3 : Listed other 11 representative iron-based amorphous-nanocrystalline soft magnetic materials in the present invention in the following table 3, the smelting process of its master alloy and the preparation of iron-based amorphous-nanocrystalline strip material The process is the same as that of Example 1 and Example 2, and its partial composition points and basic magnetic properties are shown in Table 3 (detection and measurement methods are as described above), and relevant VSM curves and DSC curves can be found in Figure 2 ~ Figure 6 .

[0054] Table 3 shows the basic magnetic properties of iron-based amorphous soft magnetic materials with some composition points

[0055] Element B(T) D (nm) Fe 80 Si 7.65 B 11.35 al 1 1.684 29.9 Fe 80 Si 7.65 B 9.35 Al 3 1.701 22.1 Fe 80 Si 3 B 14 Al 3 1.715 22.7 Fe 80 Si 6.65 B 9.35 Al 4 1.706 29.8 Fe 80 Si 6 B 11 Al 3 1.673 24.1 Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com