Barium fluoride up-conversion transparent ceramic and preparation method thereof

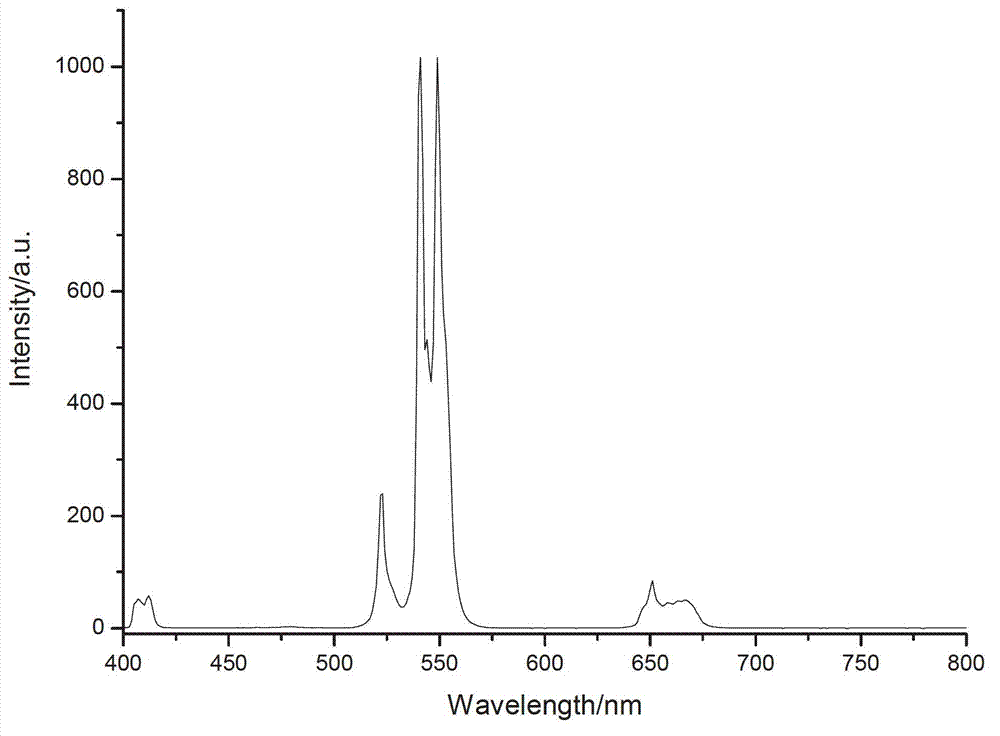

A technology of transparent ceramics and barium fluoride, applied in the field of optical functional materials, can solve the problems of poor up-conversion performance, long sintering time and high sintering temperature, and achieve the effects of good up-conversion performance, loose process conditions and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0010] The barium fluoride up-conversion transparent ceramic of the present invention is doped with rare earth ions in the transparent ceramic matrix, the transparent ceramic matrix is a barium fluoride transparent ceramic, and the molar percentage ratio of the barium fluoride up-conversion transparent ceramic is: fluoride 60-89% barium, 10-25% ytterbium fluoride, 1-15% of one or more fluorides of erbium, holmium, neodymium, thulium, promethium.

[0011] The preparation method of barium fluoride up-conversion transparent ceramics of the present invention includes vacuum sintering of transparent ceramics, specifically comprising the following steps:

[0012] 1. Preparation of nano raw material powder

[0013] According to the molar ratio of the final product - barium fluoride 60~89%, ytterbium fluoride 10~25%, and one or more fluorides of erbium, holmium, neodymium, thulium, promethium 1~15% to prepare nano raw materials powder, and the particle size of the barium fluoride p...

Embodiment 1

[0022] Embodiment 1: according to technological process, chemically pure reagent Ba(NO 3 ) 2 Dissolve in deionized water, prepare a solution with a molar concentration of 0.2M, and then add excess ammonium fluoride to generate barium fluoride (BaF 2 ) precipitation, stirred at a stirring rate of 200rpm to obtain a barium fluoride suspension, and then aged for 14 hours, washed with water and dried for 14 hours to obtain a pure phase cubic barium fluoride powder with an average particle size of 40nm. Chemically pure reagent Yb 2 o 3 (ytterbium oxide) is added to nitric acid and heated to dissolve, and prepared into a solution with a concentration of 2M, and then ammonium fluoride is added to generate YbF 3 (ytterbium fluoride) precipitation, stirred at a stirring rate of 300rpm to obtain YbF 3 The suspension was aged for 24 hours, washed with water and dried for 24 hours to obtain ytterbium fluoride powder with an average particle size of 50 nm. Also prepare erbium fluoride...

Embodiment 2

[0023] Embodiment 2: according to technological process, chemically pure reagent Ba(NO 3 ) 2 Dissolve in deionized water, prepare a solution with a molar concentration of 0.2M, and then add excess ammonium fluoride to generate barium fluoride (BaF 2 ) precipitation, stirred at a stirring rate of 200rpm to obtain a barium fluoride suspension, and then aged for 14 hours, washed with water and dried for 14 hours to obtain a pure phase cubic barium fluoride powder with an average particle size of 40nm. Chemically pure reagent Yb 2 o 3 (ytterbium oxide) is added to nitric acid and heated to dissolve, and prepared into a solution with a concentration of 2M, and then ammonium fluoride is added to generate YbF 3 (ytterbium fluoride) precipitation, stirred at a stirring rate of 300rpm to obtain YbF 3 The suspension was aged for 24 hours, washed with water and dried for 24 hours to obtain ytterbium fluoride powder with an average particle size of 50 nm. Also prepare erbium fluoride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com