Titanium-aluminate-based up-conversion luminescent material, preparation method and application

A luminescent material, a technology of titanialuminate, which is applied in the field of upconversion luminescent material, preparation, and titanoaluminate-based upconversion luminescent material, which can solve the problems of insufficient stability, the influence of the use and popularization of upconversion luminescent material, and the preparation process Complicated and other issues, to achieve stable luminous performance, improve up-conversion luminous efficiency, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of Ba 3.796 Er 0.004 Yb 0.2 Ti 10 Al 2 o 27

[0037] According to the chemical formula Ba 3.76 Er 0.04 Yb 0.2 Ti 10 Al 2 o 27 , weigh barium carbonate BaCO 3 : 4.9941 g, titanium dioxide TiO 2 : 5.3244 grams, aluminum nitrate Al (NO 3 ) 3 9H 2 O: 2.8399 grams, erbium oxide Er 2 o 3 : 0.0053 g, ytterbium oxide Yb 2 o 3 : 0.2720 g, fully ground in an agate mortar and mixed evenly, placed in an alumina crucible, pre-calcined for the first time under air atmosphere, calcined at 400 ° C for 6 hours in a muffle furnace, cooled to room temperature , after taking out the sample, fully mix and grind evenly; then pre-calcine for the second time in an atmosphere containing oxygen, calcinate in a muffle furnace at 600 ° C for 8 hours, cool to room temperature, take out the sample and mix well again and grind evenly; finally Calcining in a muffle furnace at 1100° C. for 10 hours in an atmosphere containing oxygen, and cooling to room temperature, the ...

Embodiment 2

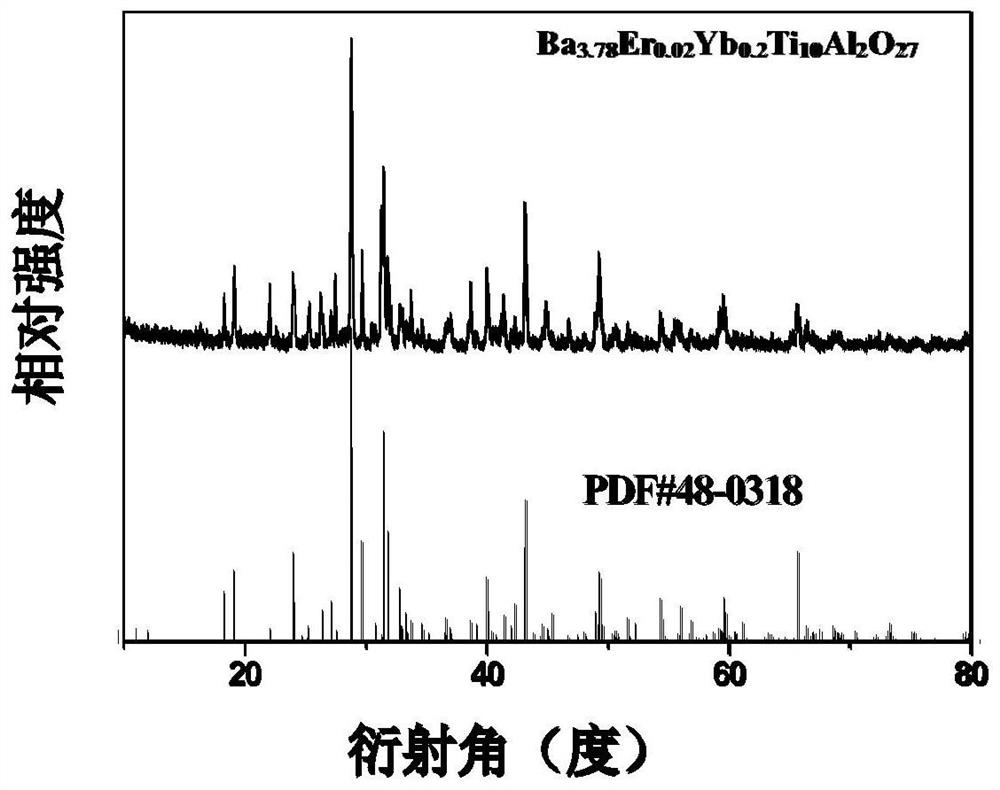

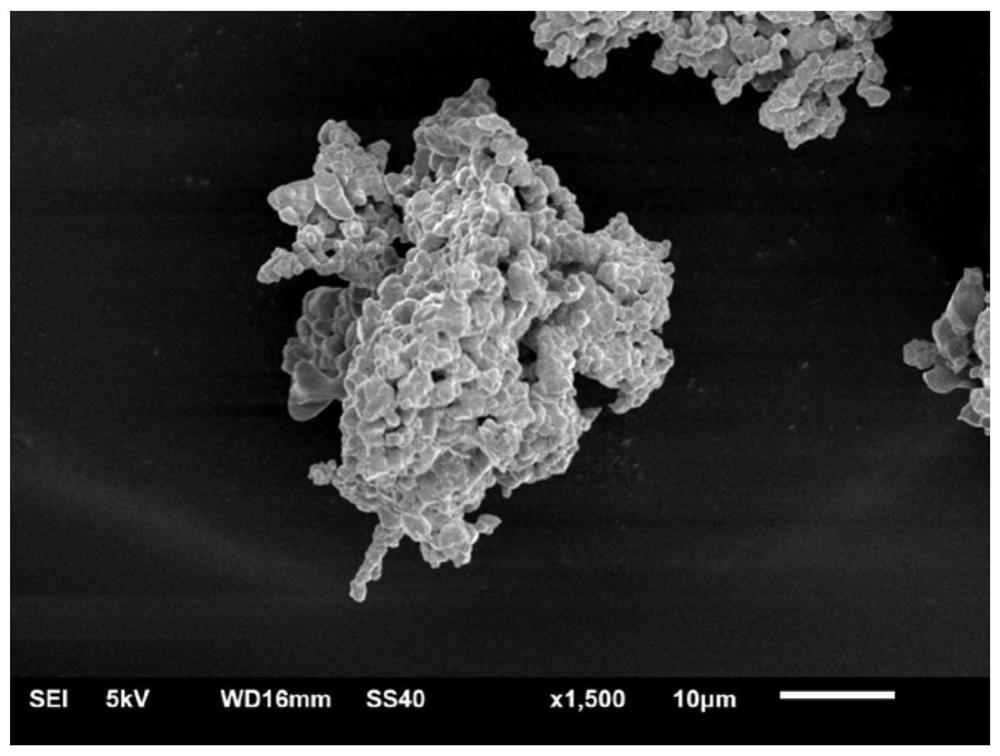

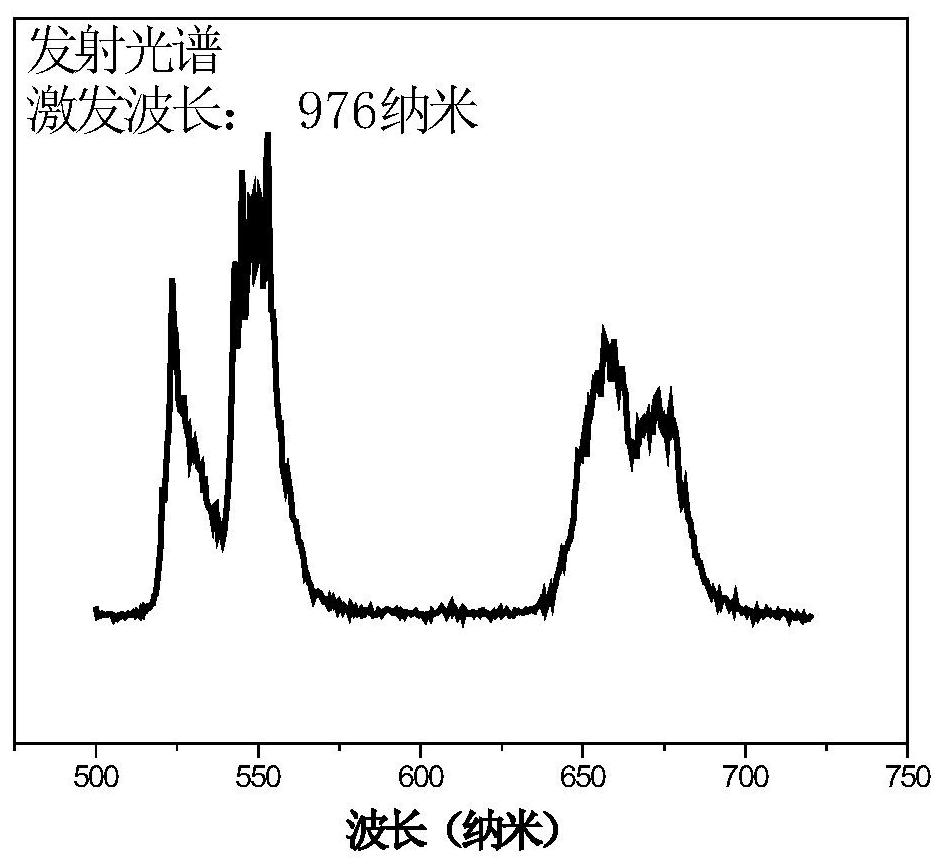

[0042] Preparation of Ba 3.78 Er 0.02 Yb 0.2 Ti 10 Al 2 o 27

[0043] According to the chemical formula Ba 3.78 Er 0.02 Yb 0.2 Ti 10 Al 2 o 27 , weigh barium nitrate Ba(NO 3 ) 2 : 6.5860 g, titanium dioxide TiO 2 : 5.3244 g, aluminum oxide Al 2 o 3 : 0.6798 g, erbium oxide Er 2 o 3 : 0.0264 g, ytterbium oxide Yb 2 o 3 : 0.2720 grams, fully ground and mixed uniformly in an agate mortar, placed in an alumina crucible, pre-calcined for the first time under air atmosphere, pre-calcined for 5 hours at 350 ° C in a muffle furnace, cooled to At room temperature, after taking out the sample, fully mix and grind evenly; then pre-calcine for the second time in an atmosphere containing oxygen, pre-calcine in a muffle furnace at 550°C for 6 hours, cool to room temperature, take out the sample and mix thoroughly and grind evenly again; Finally, in an atmosphere containing oxygen, calcinate at 1050° C. for 8 hours in a muffle furnace, and cool to room temperature to obta...

Embodiment 3

[0046] Preparation of Ba 3.76 Er 0.04 Yb 0.2 Ti 10 Al 2 o 27

[0047] According to the chemical formula Ba 3.76 Er 0.04 Yb 0.2 Ti 10 Al 2 o 27 , Weigh barium hydroxide Ba(OH) 2 : 4.2951 g, titanium dioxide TiO 2 : 5.3244 g, aluminum carbonate Al 2 (CO 3 ) 3 : 1.560 g, erbium oxide Er 2 o 3 : 0.0528 g, ytterbium oxide Yb 2 o 3 : 0.2720 g, fully ground in an agate mortar and mixed evenly, placed in an alumina crucible, pre-calcined for the first time under air atmosphere, calcined at 500 ° C for 8 hours in a muffle furnace, cooled to room temperature , after taking out the sample, fully mix and grind evenly; then pre-calcine for the second time in an atmosphere containing oxygen, calcinate in a muffle furnace at 700 ° C for 10 hours, cool to room temperature, take out the sample and mix well again and grind evenly; finally in Calcining in a muffle furnace at 1200° C. for 12 hours in an atmosphere containing oxygen and cooling to room temperature can obtain an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com