Fluorosilicate-based up-conversion luminescent ceramic material and preparation method thereof

A technology of luminescent ceramics and fluorosilicate, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of complex preparation process, insufficient stability, the use and popularization and application of up-conversion luminescent materials, etc., and achieve good repeatability , Improve the excitation stability, and the effect of rich raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of Ca 9.45 Er 0.05 Yb 0.5 Si 3 o 15 f 2 , according to the chemical formula Ca 9.45 Er 0.05 Yb 0.5 Si 3 o 15 f 2 The stoichiometric ratio of each element in, weighed calcium carbonate CaCO 3 : 8.503 g, silicon oxide SiO 2 : 1.8024 g, erbium oxide Er 2 o 3 : 0.0010 g, ytterbium oxide Yb 2 o 3 : 0.010 g, ground and mixed uniformly in an agate mortar, pre-sintered in an air atmosphere, the sintering temperature is 800 ° C, the sintering time is 10 hours, then cooled to room temperature, the sample is taken out and ground and mixed uniformly; the pre-sintered mixture is mixed with 0.7808 g calcium fluoride CaF 2Thoroughly mix and grind evenly, and press the mixed powder with a pressing pressure of 10 MPa, then calcinate again in an air atmosphere, calcining temperature is 1100°C, calcining time is 5 hours, naturally cool, grind and mix uniformly to obtain calcium fluorosilicate fluorescent ceramics.

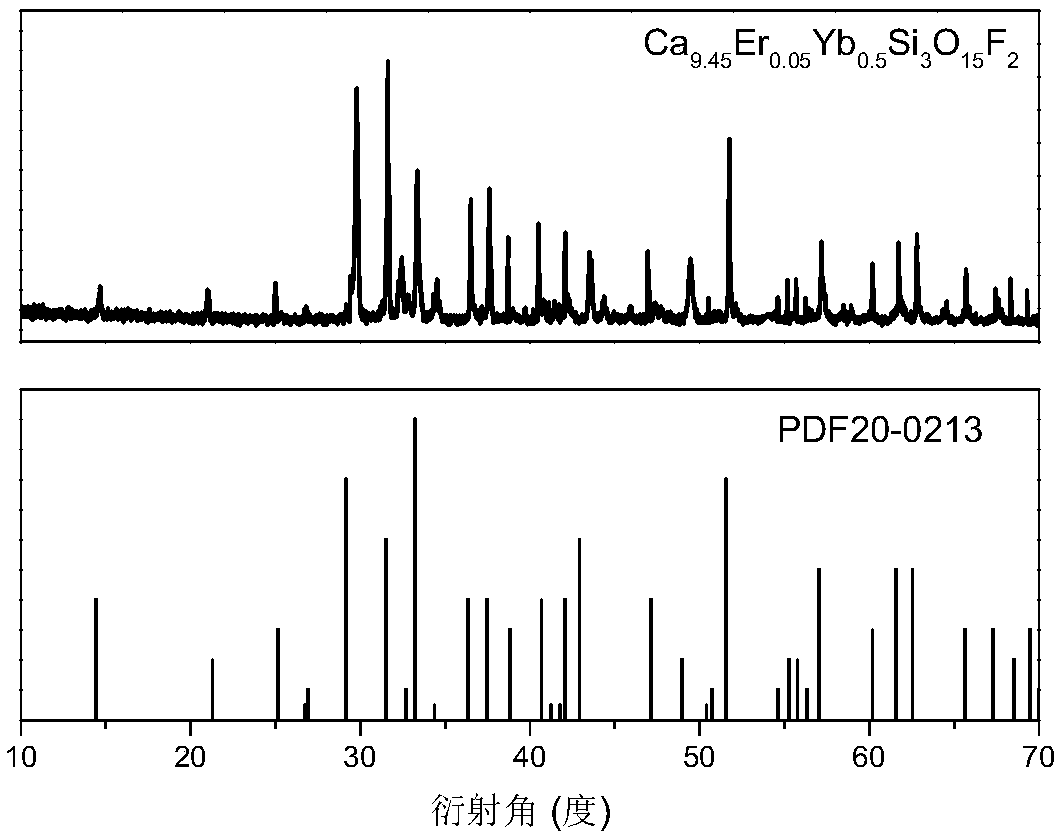

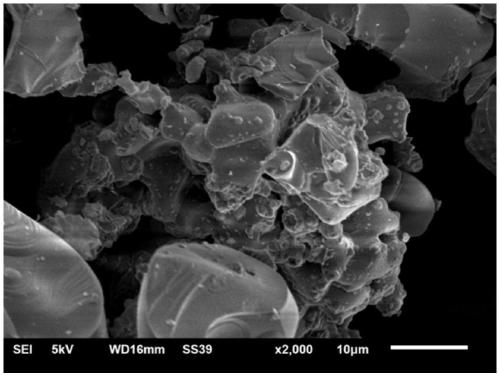

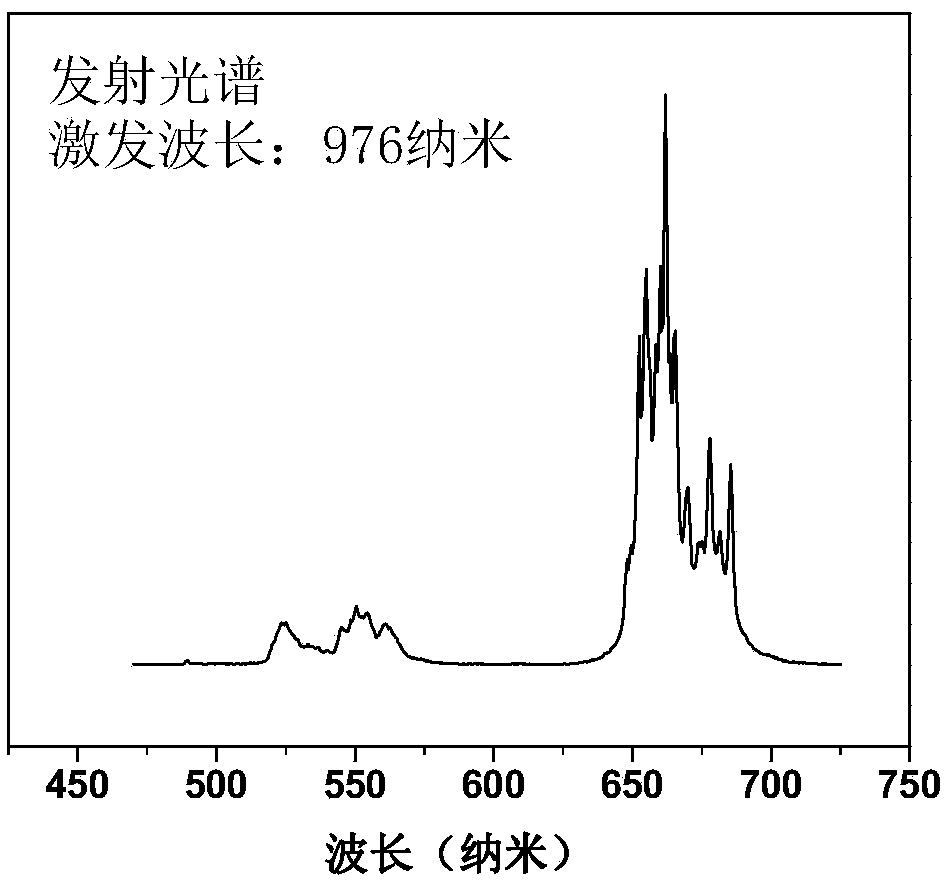

[0028] See attached figure 1 , which is the...

Embodiment 2

[0032] Preparation of Ca 9.49 Er 0.01 Yb 0.5 Si 3 o 15 f 2 , according to the chemical formula Ca 9.49 Er 0.01 Yb 0.5 Si 3 o 15 f 2 The stoichiometric ratio of each element in , respectively weigh calcium hydroxide Ca(OH) 2 : 4.9648 g, silicic acid H 2 SiO 3 : 2.34 g, erbium oxide Er 2 o 3 : 0.0020 g, ytterbium oxide Yb 2 o 3 : 0.010 g, ground and mixed uniformly in an agate mortar, pre-sintered in an air atmosphere, the sintering temperature is 950 ° C, the sintering time is 3 hours, then cooled to room temperature, the sample is taken out and ground and mixed uniformly; the pre-sintered raw material is mixed with 2.3424 grams of calcium fluoride CaF 2 Thoroughly mix and grind evenly, and press the mixed powder with a pressing pressure of 15 MPa, then calcinate again in an air atmosphere, calcining temperature is 950°C, calcining time is 10 hours, naturally cool, grind and mix evenly to obtain calcium fluorosilicate fluorescent ceramics.

[0033] The X-ray p...

Embodiment 3

[0035] Preparation of Ca 9.4 Er 0.1 Yb 0.5 Si 3 o 15 f 2 , according to the chemical formula Ca 9.4 Er 0.1 Yb 0.5 Si 3 o 15 f 2 The stoichiometric ratio of each element in , respectively weigh calcium oxalate CaC 2 o 4 : 9.507 g, silicic acid H 2 SiO 3 : 2.34 g, erbium oxide Er 2 o 3 : 0.020 g, ytterbium oxide Yb 2 o 3 : 0.010 g, ground and mixed in an agate mortar, pre-sintered in an air atmosphere, the sintering temperature is 900 ° C, the sintering time is 4 hours, then cooled to room temperature, the sample is taken out and ground and mixed evenly; the pre-sintered raw materials are again with 1.5616 g of calcium fluoride CaF 2 Thoroughly mix and grind evenly, and press the mixed powder into shape, the pressing pressure is 12MPa, calcined again in the air atmosphere, the calcining temperature is 900°C, the calcining time is 15 hours, the natural cooling is ground and mixed evenly to obtain calcium fluorosilicate fluorescent ceramics.

[0036] The X-ray p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com