Hollow tungsten electrode arc coaxial laser composite wire filling welding method

A welding method and laser technology, applied in laser welding equipment, arc welding equipment, welding equipment, etc., can solve the problems of poor melting ability of heat source welding wire, low deposition efficiency, reduction of current density, temperature, and plasma flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

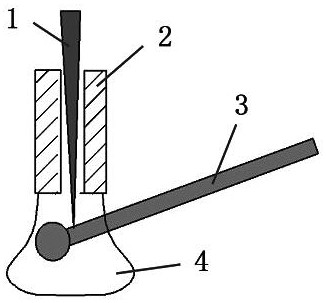

[0025] A hollow tungsten arc coaxial laser composite filler wire welding method. After the laser passes through the central hole of the tungsten electrode, the laser spots directly act on the surface of the welding wire to realize the combined heating and melting of the welding wire by laser-hollow tungsten arc. The method includes the following steps:

[0026] Step 1: Before welding, grind or clean the workpiece to be welded, and fix the polished or cleaned workpiece to be welded;

[0027] Step 2: Adjust the relative position of the laser and the axis of the hollow tungsten pole so that the laser passes through the center of the hollow tungsten pole. Use side-axis wire feeding to adjust the feeding angle and position of the welding wire so that the laser beam passes through the hollow tungsten electrode and directly irradiates the surface of the welding wire;

[0028] Step 3: Set the hollow tungsten electrode arc parameters and laser parameters, set the hollow tungsten electr...

Embodiment 2

[0032] According to the hollow tungsten arc coaxial laser composite wire filling welding method described in embodiment 1, the laser adopts CO 2 Gas laser, YAG solid-state laser, semiconductor laser or fiber laser; laser output is continuous laser or pulsed laser.

Embodiment 3

[0034] According to the hollow tungsten arc coaxial laser composite wire filling welding method described in embodiment 1 or 2, the laser is a double-beam laser, the laser power ratio of the double-beam laser is continuously adjustable, and the beam arrangement is continuously adjustable for 360 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com