Patents

Literature

39results about How to "High dilution rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

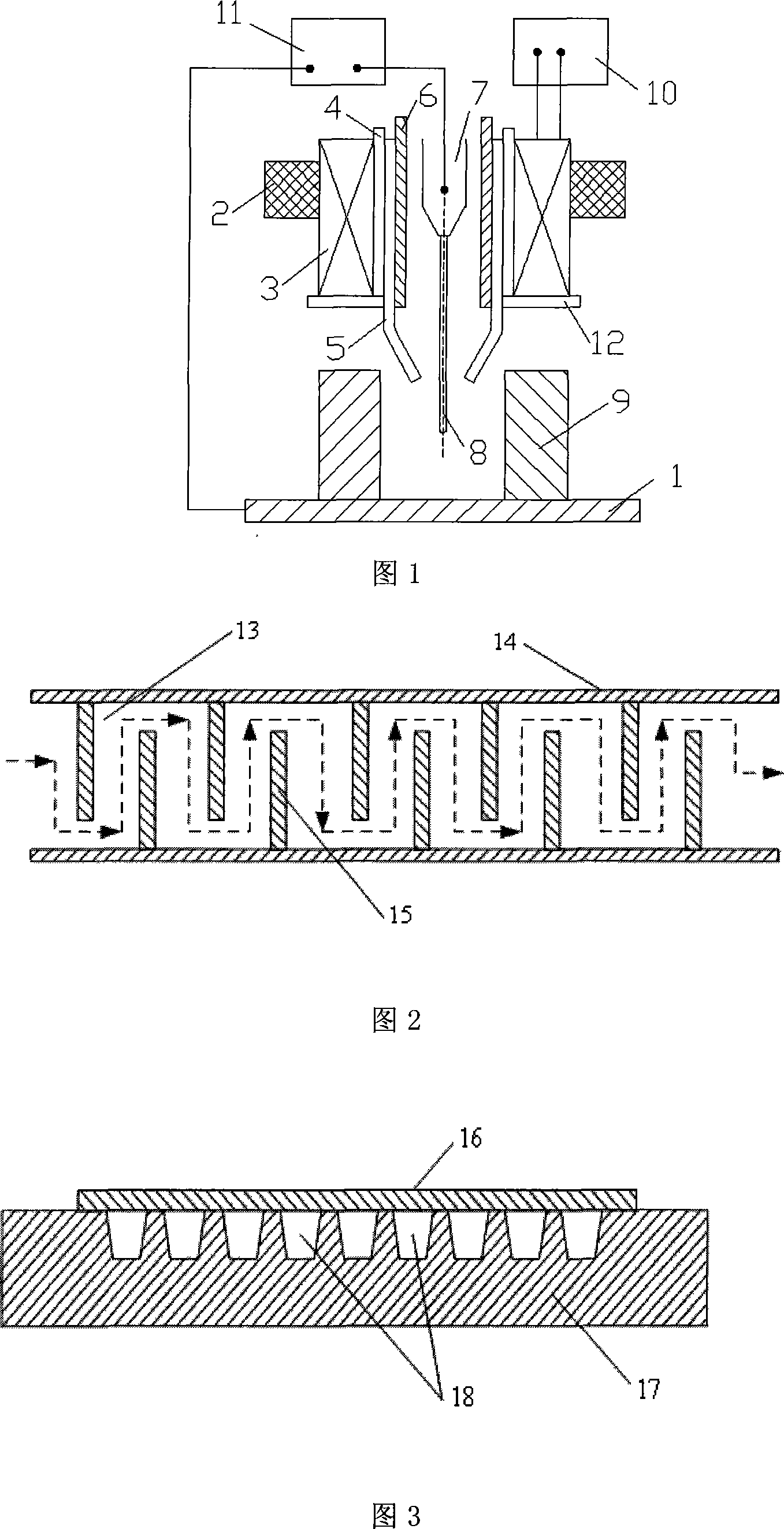

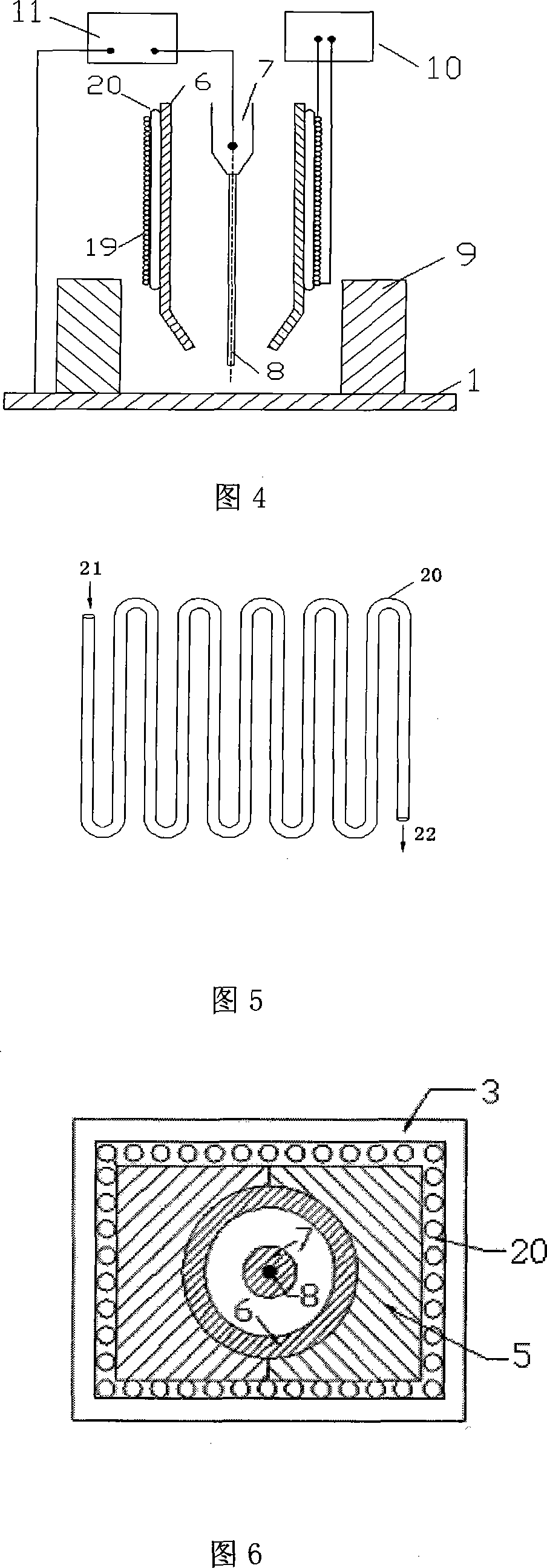

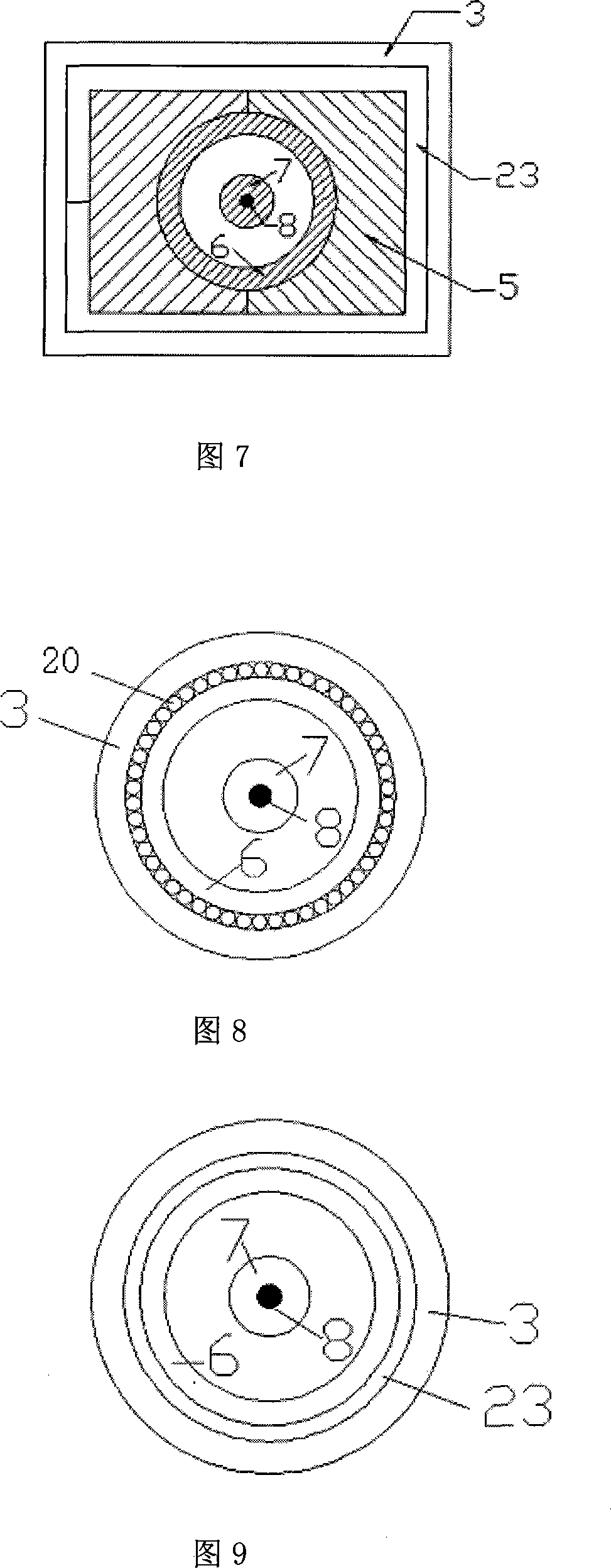

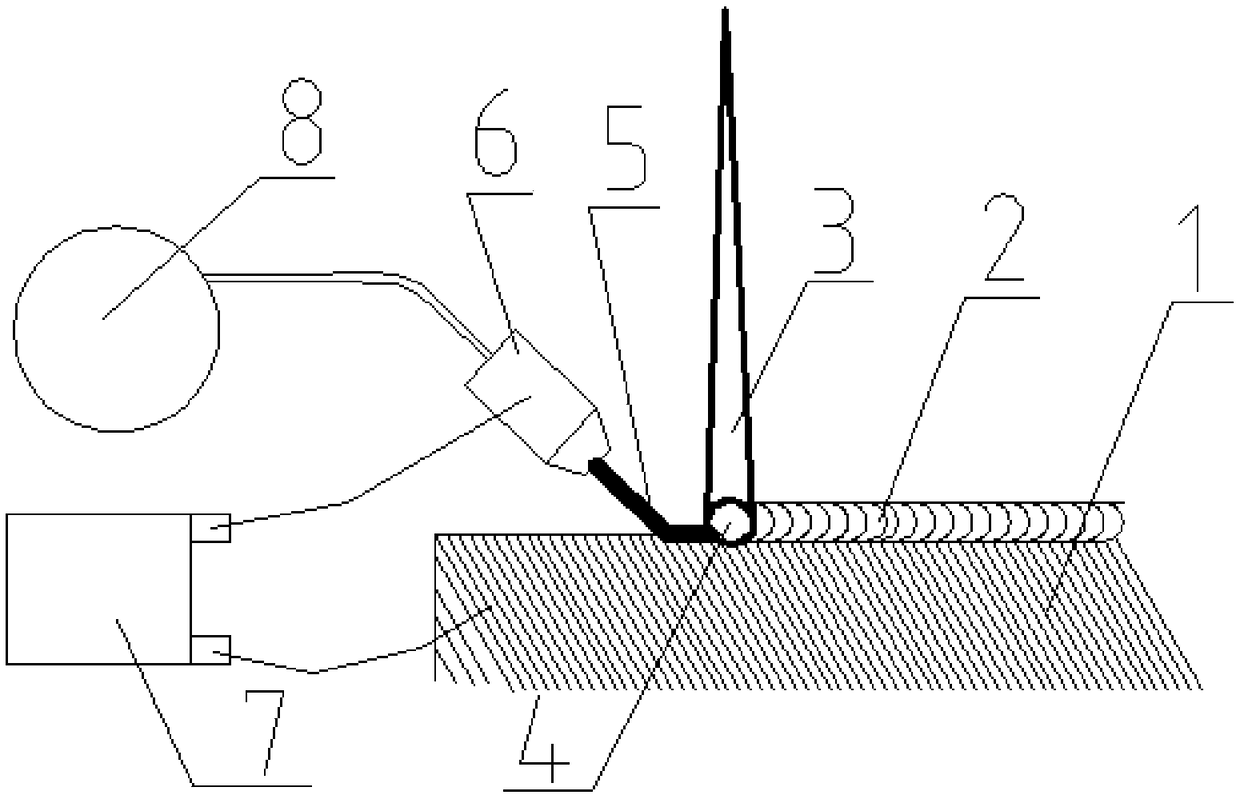

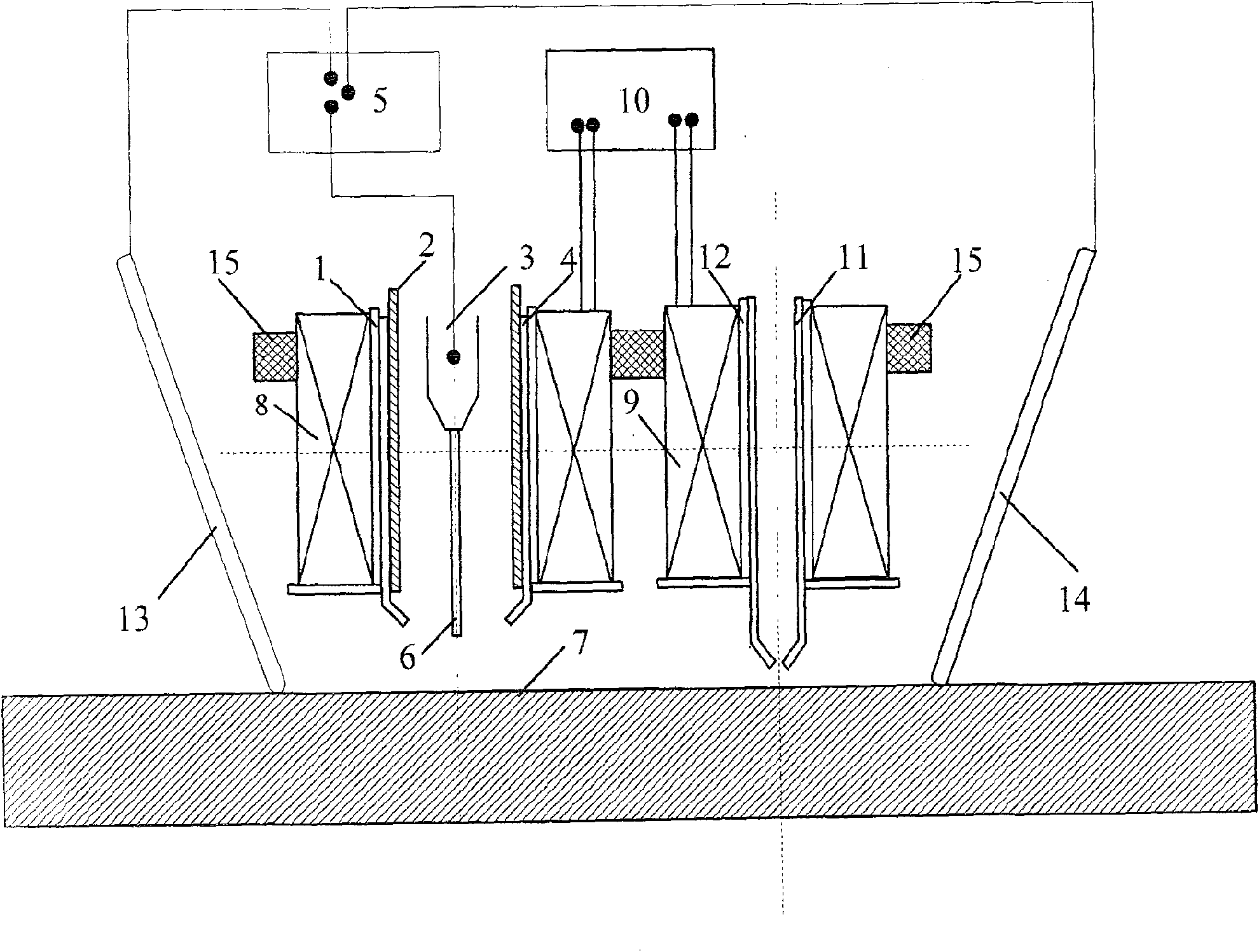

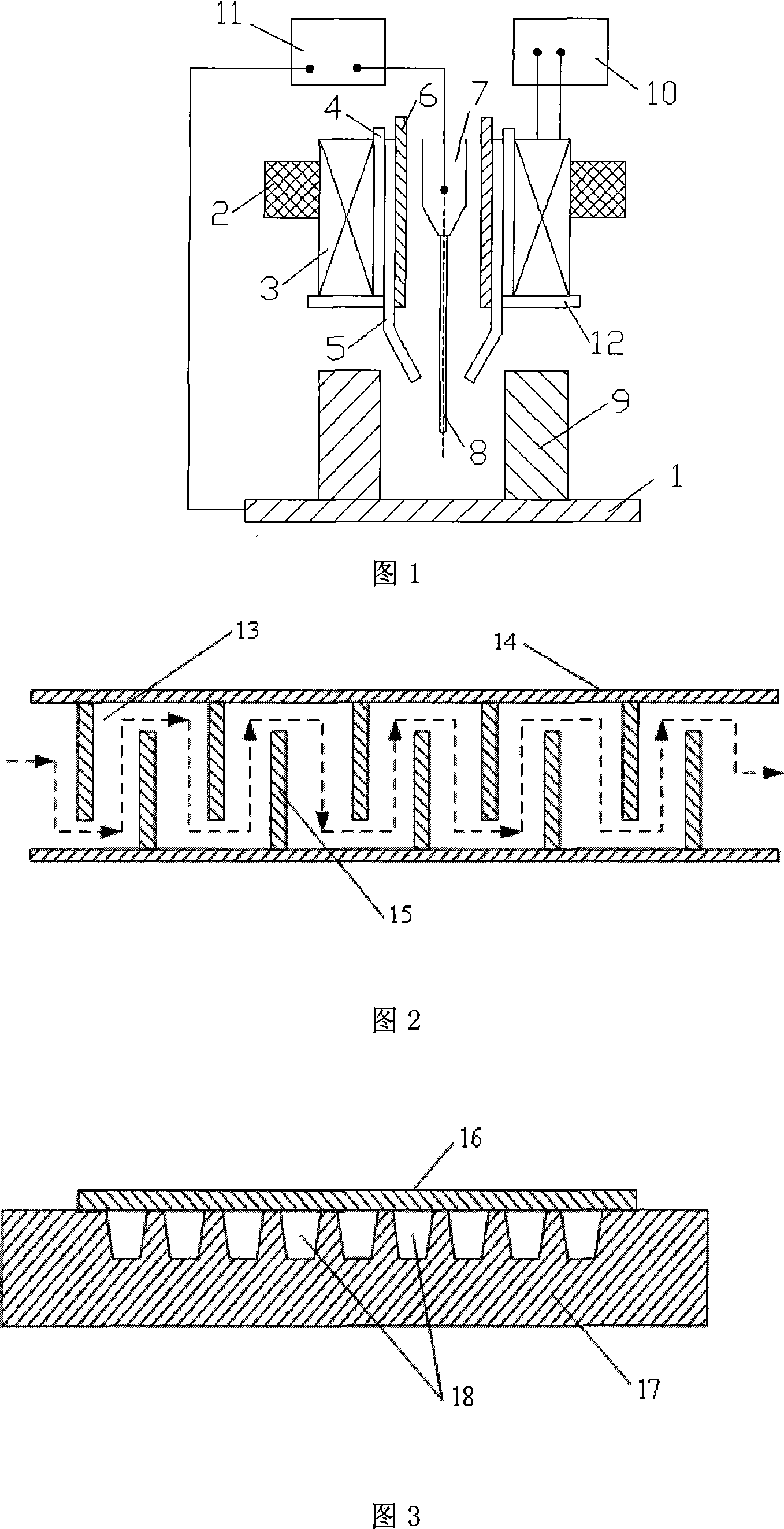

Moderate and high strength large-thickness component electromagnetic controlling narrow gap or ultra-narrow gap pulse efflux molten electrode gas-shield welding method and equipment

InactiveCN101143401AOvercoming arcingImprove crystallizationTransformers/inductances coolingWelding/cutting media/materialsElectric arcEngineering

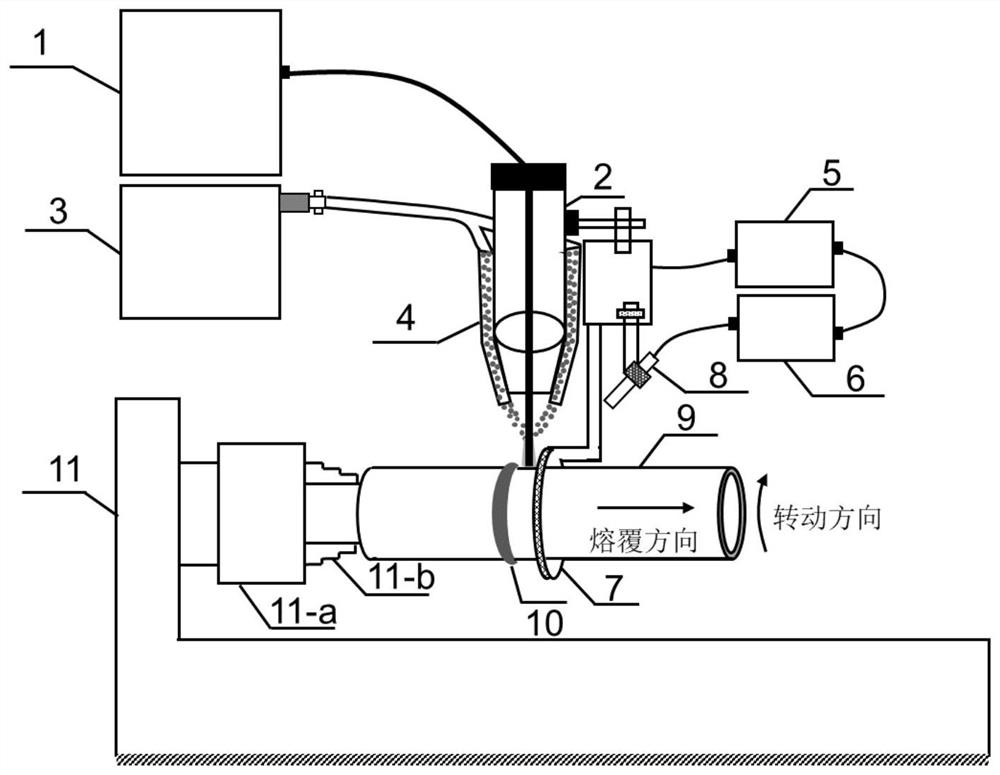

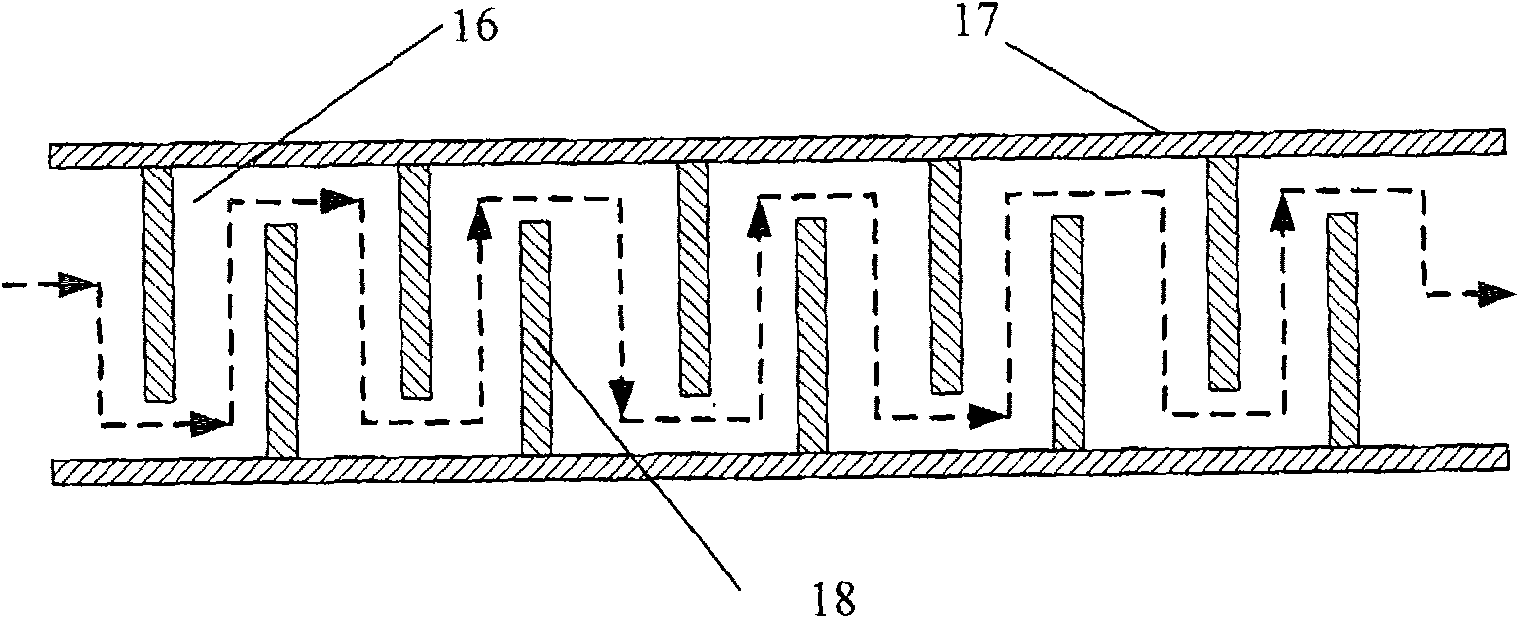

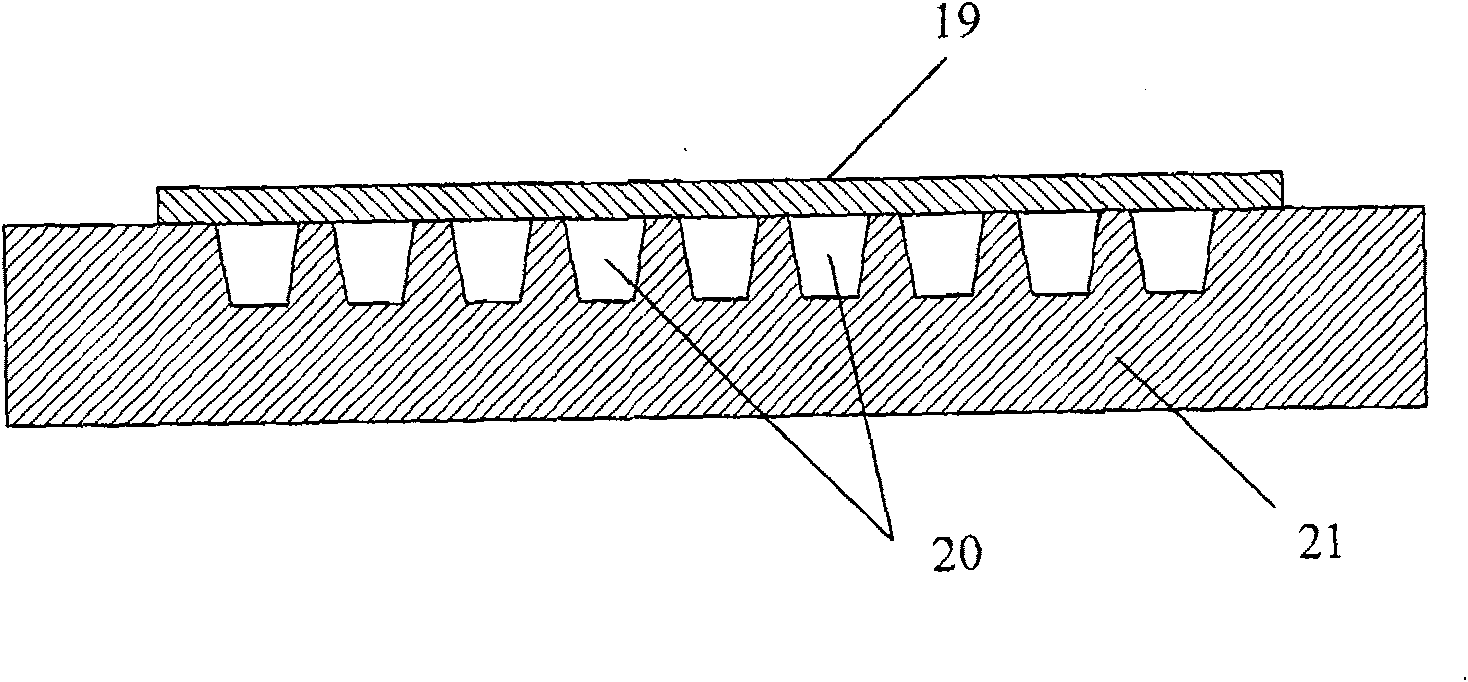

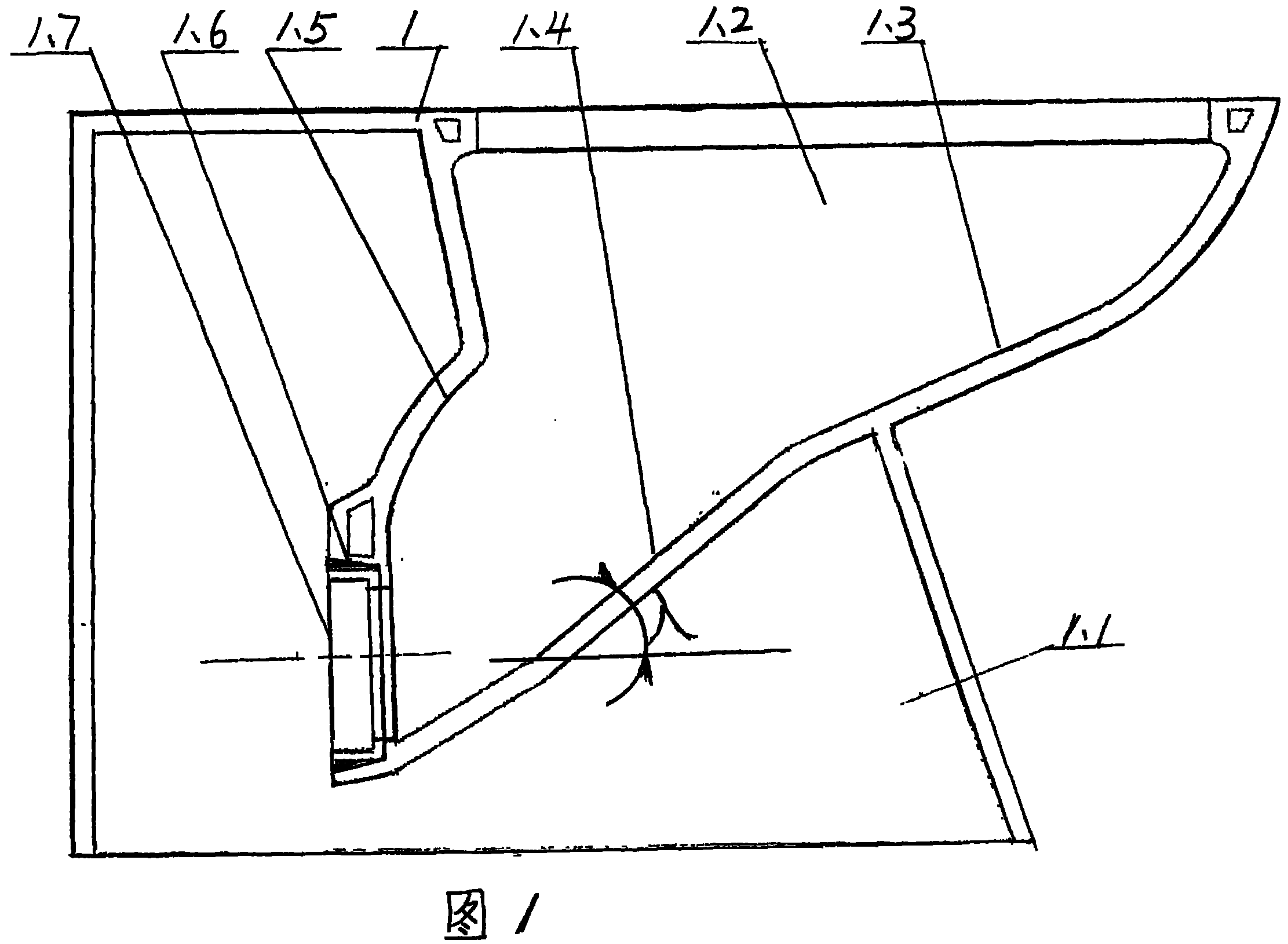

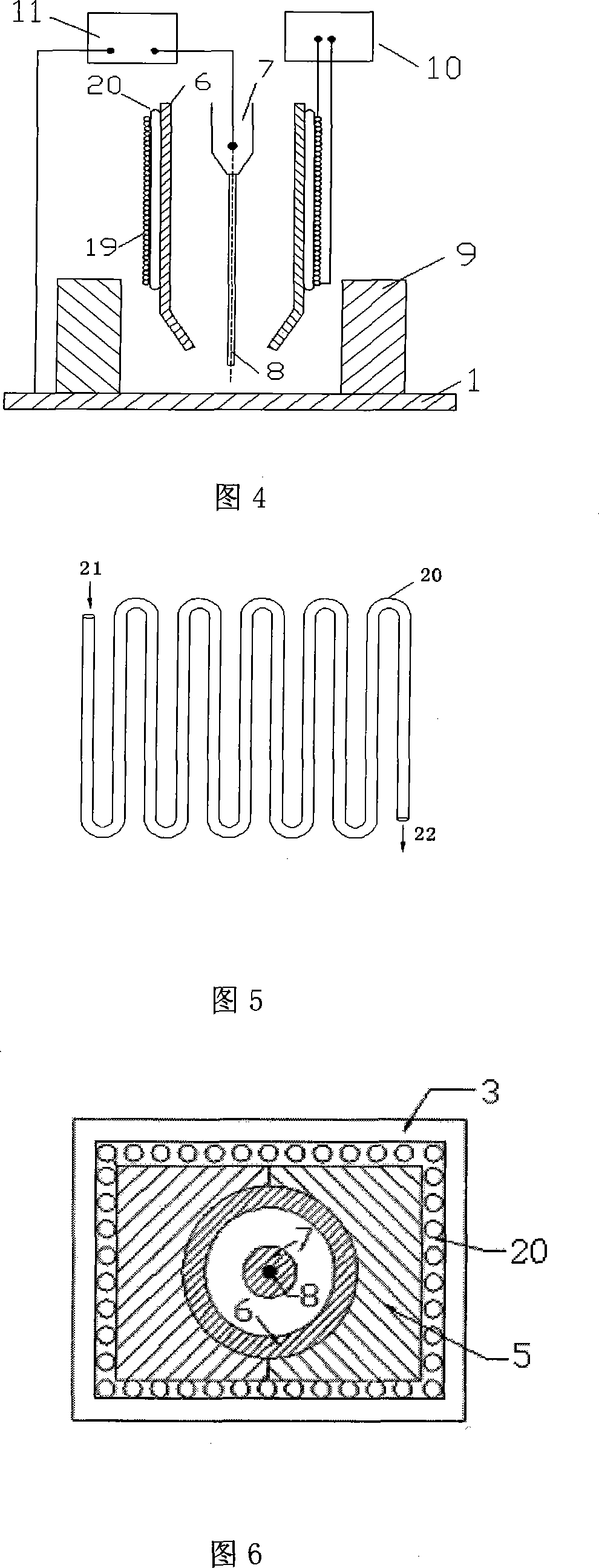

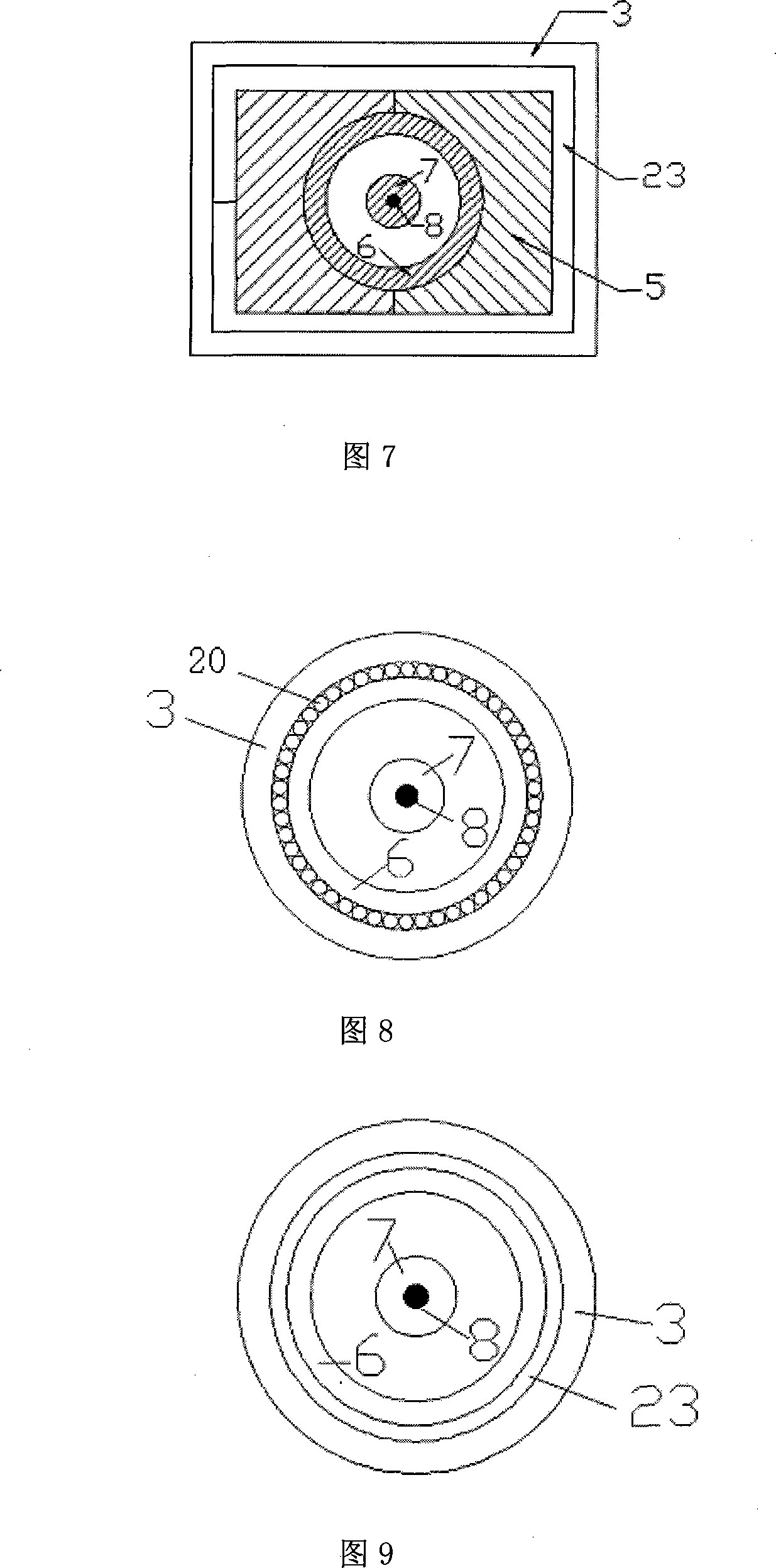

The invention relates to a gas shielded welding method and device of a narrow gap or a super-narrow gap impulse jet current consumable electrode controlled by electromagnetic of the heavy section part with middle and high strength. The invention uses a magnetic coil (3) to provide excitation current processed by an excitation source, which can generate an extra magnetic field. Under the conditions of narrow gap or super-narrow gap, high feed rate, fused drop spray transfer and impulse welding current, the process of the gas shielded welding of the rotating jet current consumable electrode with high-melting frequency pulse that is controlled by the electromagnetic for the heavy section part with middle and high strength can be realized. The device of the invention comprises the excitation source, excitation equipment, auxiliary equipment and a water cooling system. The excitation equipment is the magnetic coil (3) with or without a conducting core (5). The excitation equipment is fixed on a welding burner (6), which is positioned above a work piece (9). The excitation current provided by the excitation source (10) produces stationary or time-varying electromagnetic mixing magnetic field that has the combination control over the processes of arc welding, wire burn-off, drop transfer, melting bath flow and welding line coagulation, which finally forms the welding line of good quality.

Owner:CHONGQING UNIV

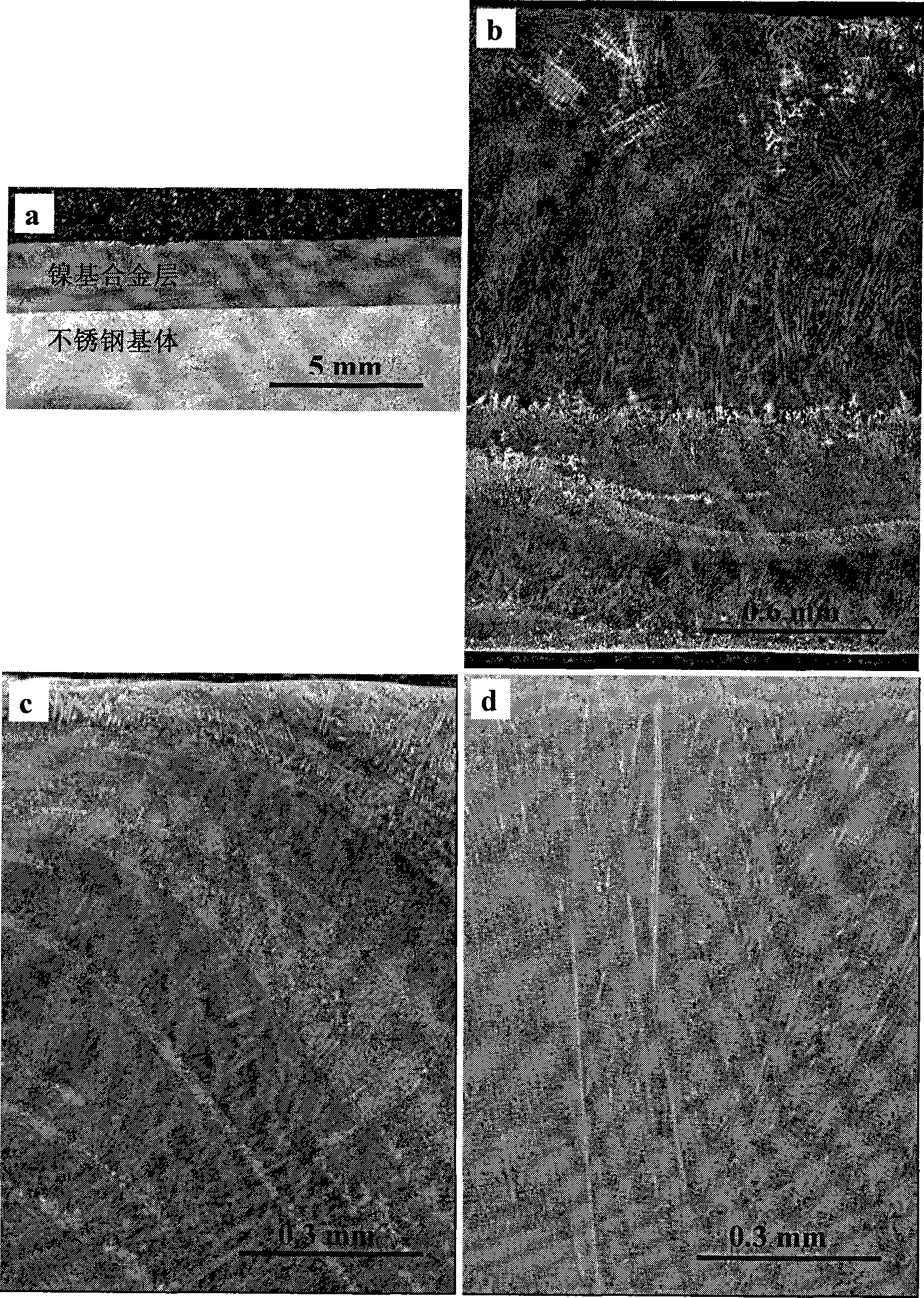

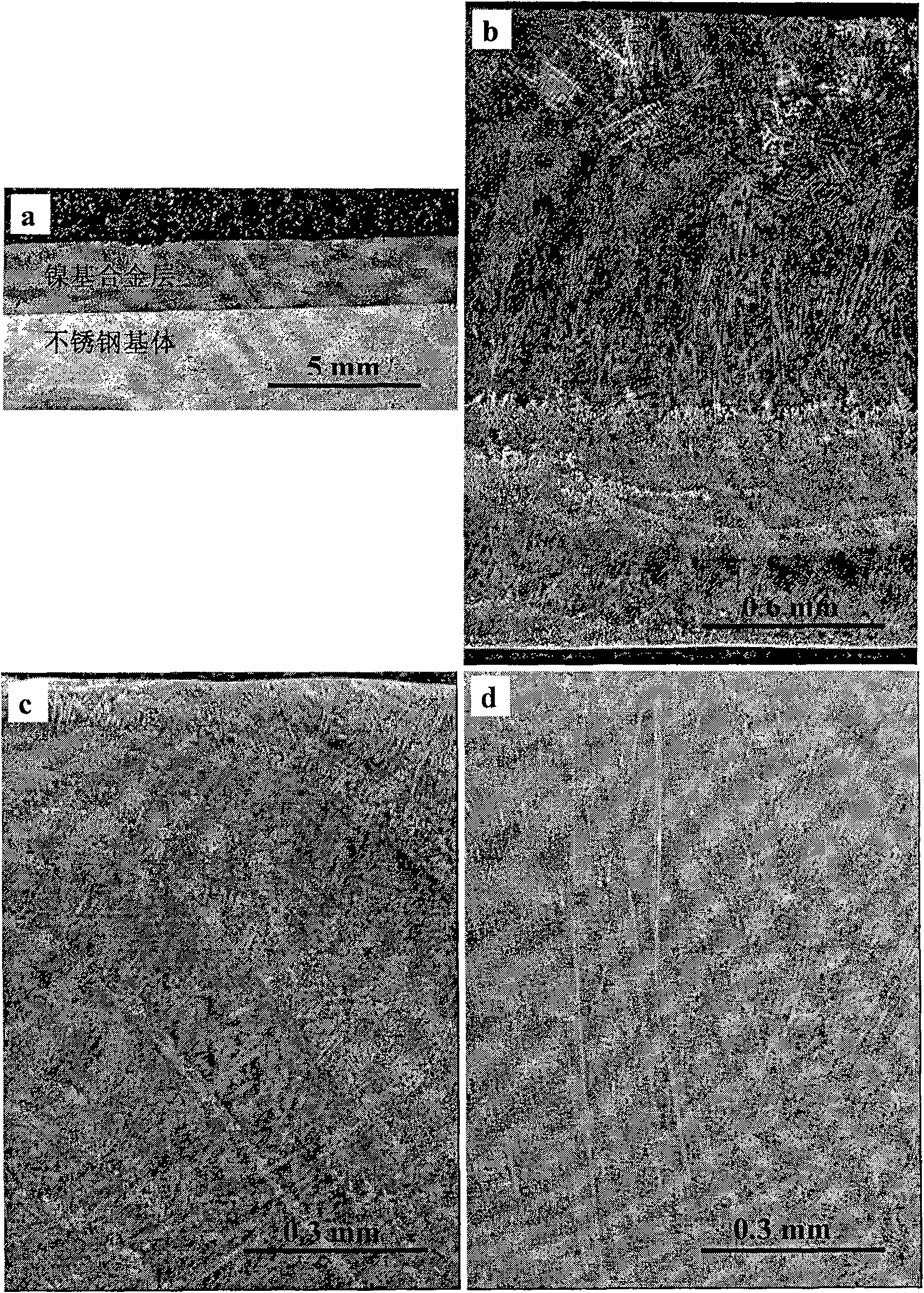

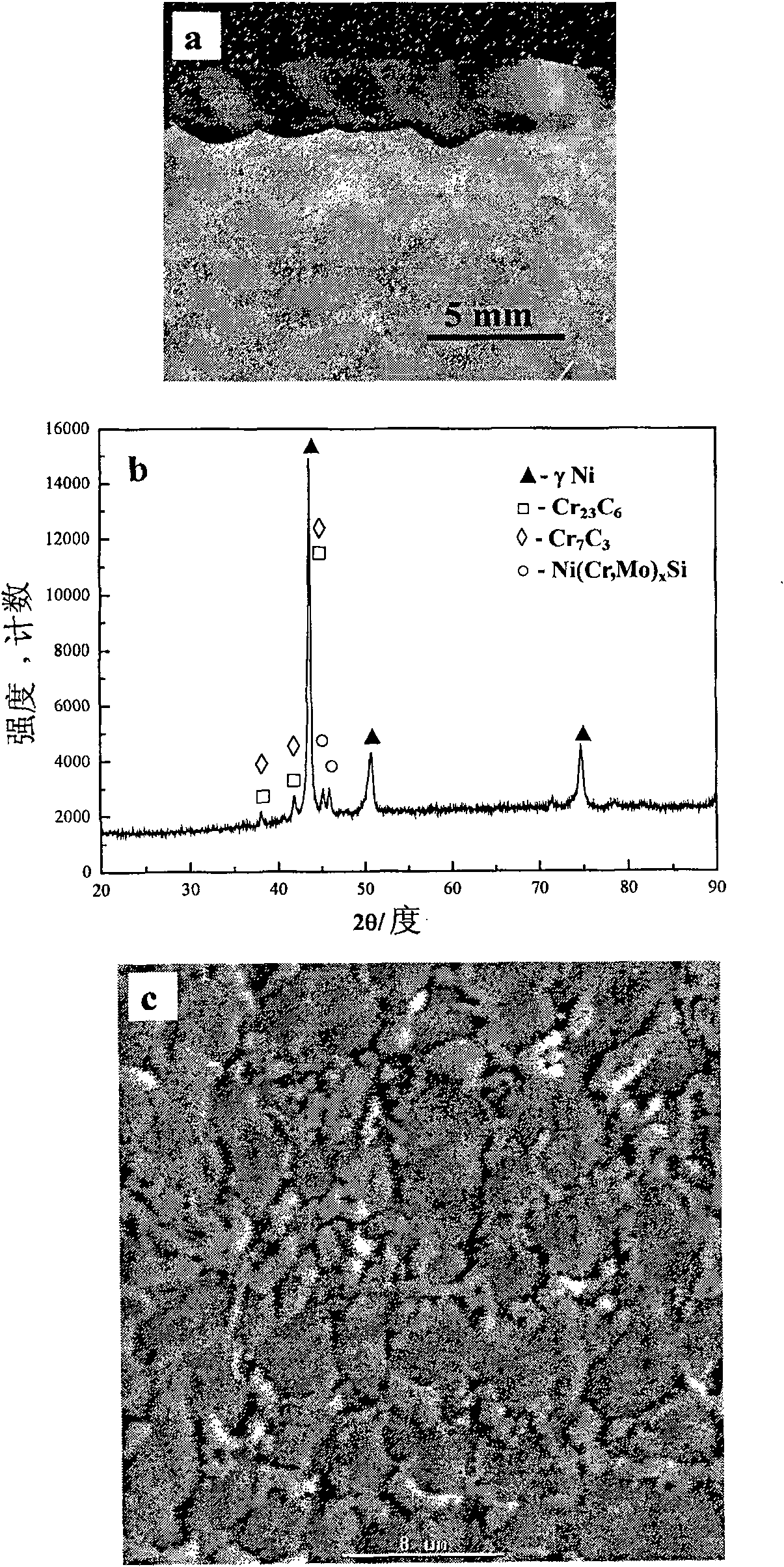

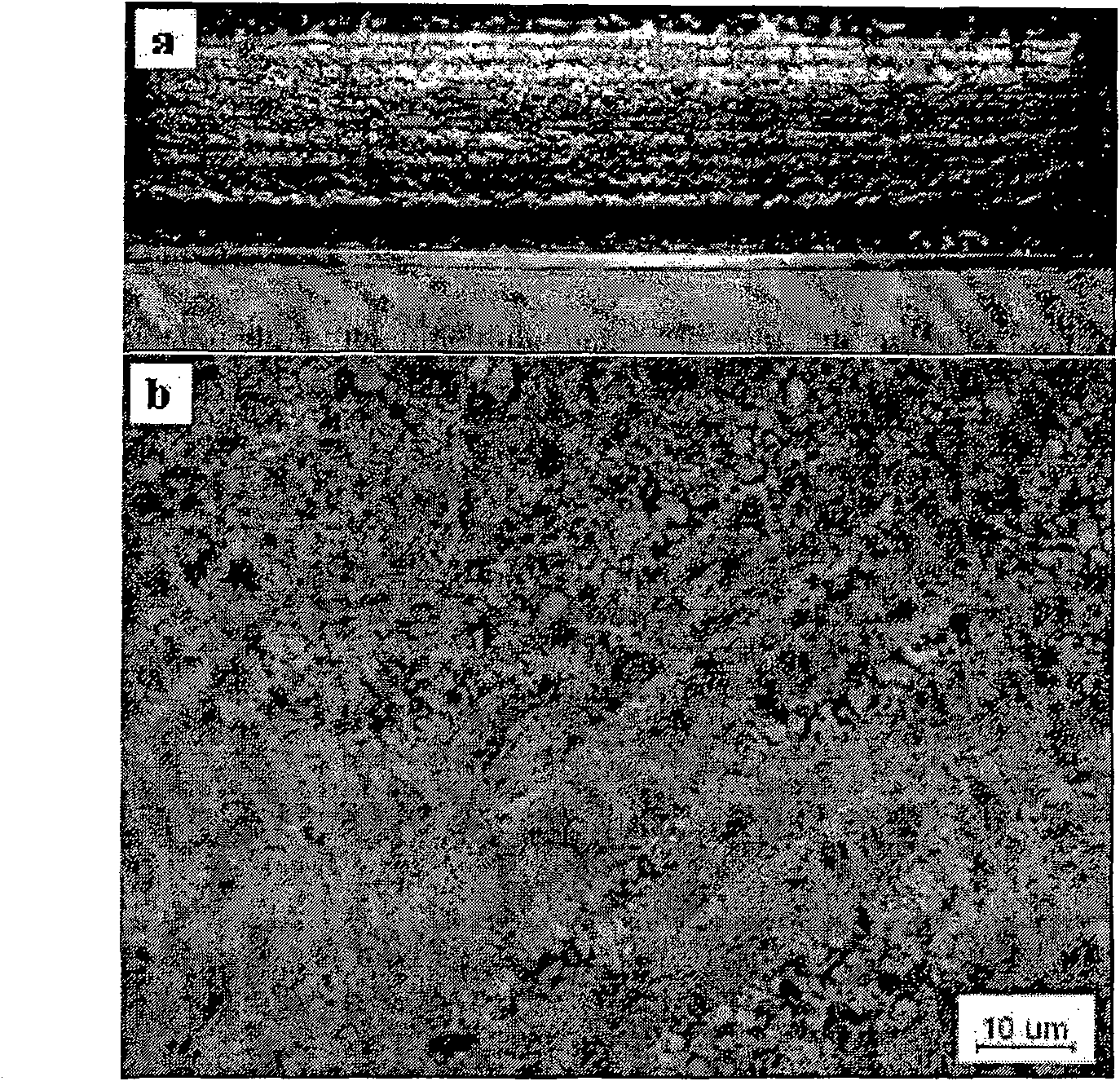

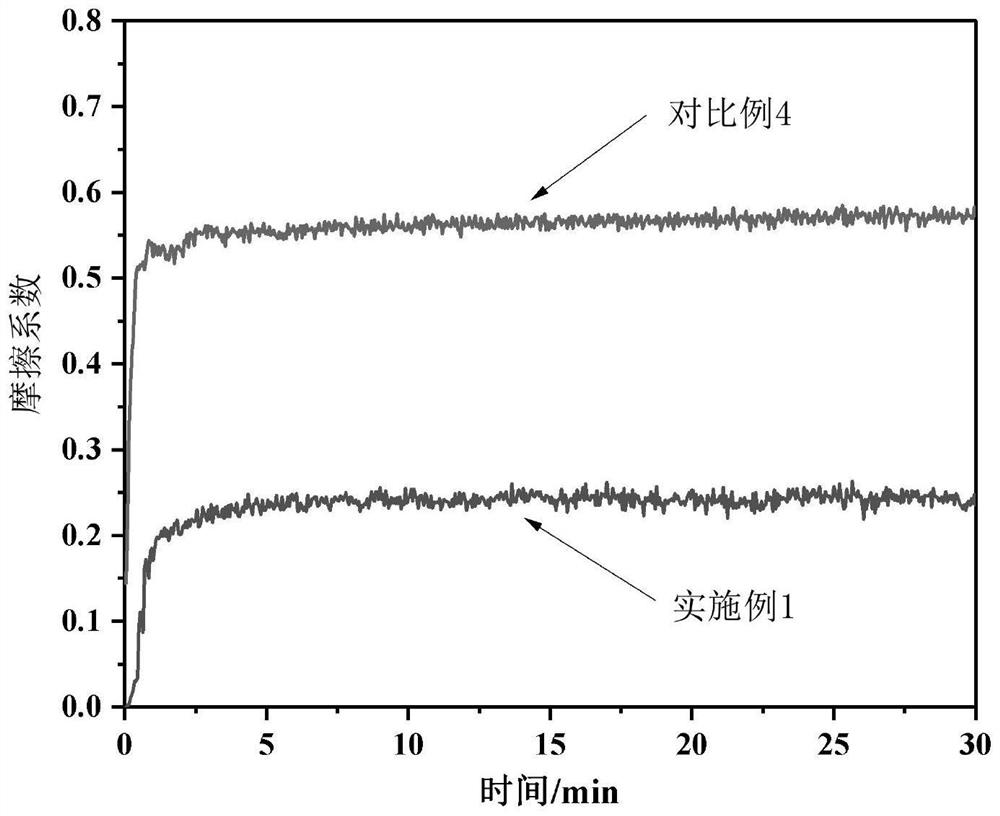

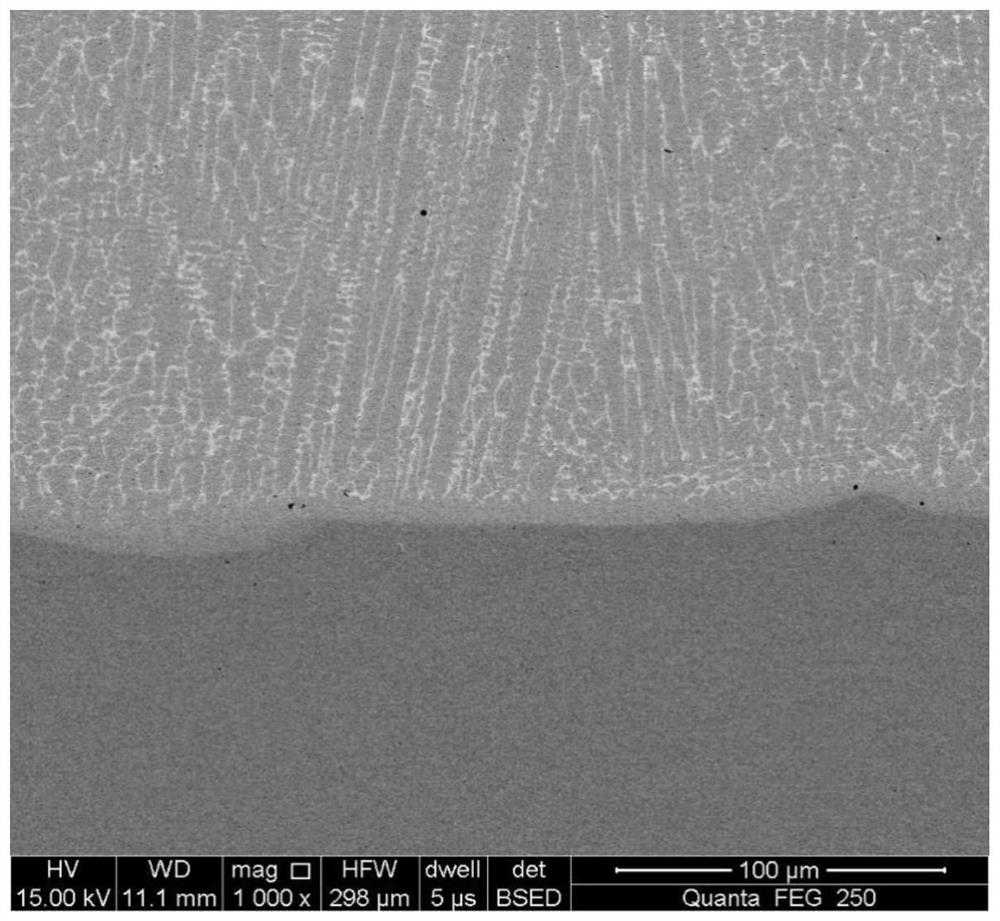

Nickel base alloy and stainless steel valve with nickel base alloy layer sealing surface, and production method thereof

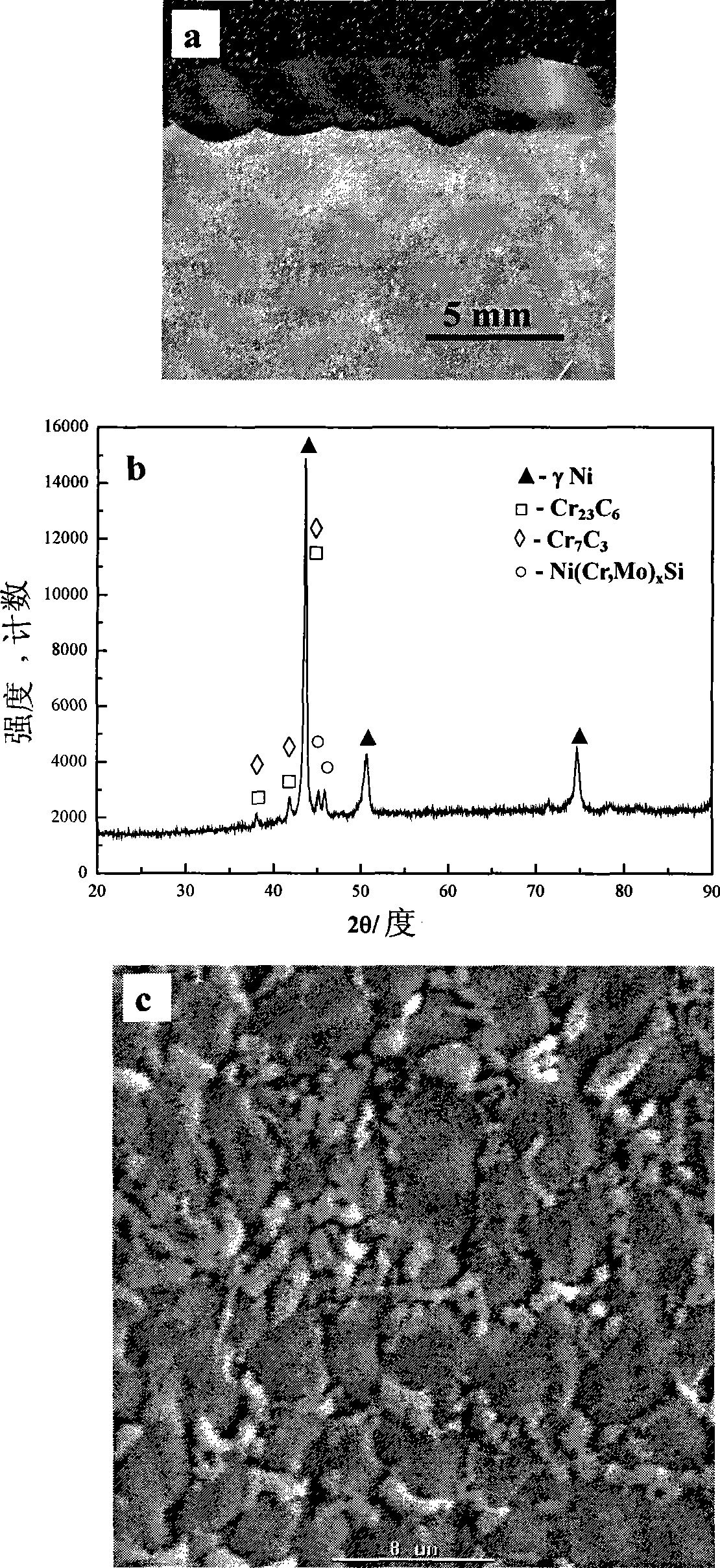

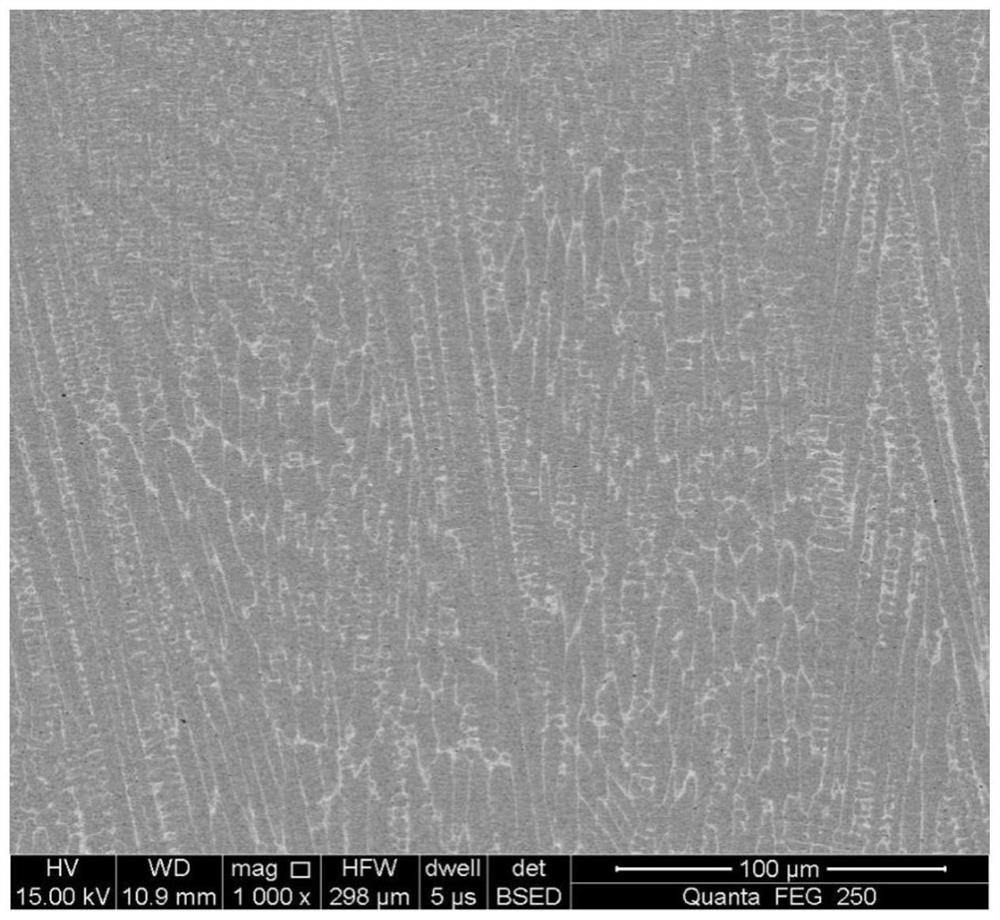

ActiveCN101368239AHigh dilution rateHigh hardnessMetallic material coating processesMetal silicideMetal

The invention relates to a nickel-based alloy, a stainless steel valve provided with a seal surface of a nickel-based alloy layer and a preparation method. The components and the contents of the nickel-based alloy used on the seal surface of the nickel-based alloy layer are respectively: 1.0 to 1.5wt percent of C, 17.5 to 19.5wt percent of Cr 7.0 to 9.0wt percent of Mo, 3.5 to 4.5wt percent of W, 1.5 to 2.5wt percent of Nb, 2.0 to 3.0wt percent of Si and the rest is Ni. The stainless steel valve provided with a seal surface of a nickel-based alloy layer is lead the powder of the nickel-based alloy to form a seal surface nickel-based alloy on the stainless steel valve through a laser plating method. The nickel-based alloy layer and a stainless steel matrix are completely metallurgically bonded without the defects like cracks, air holes, and the like. The alloy layer comprises nickel-based solid solution dendrites, the metallic carbides between the dendrites, the metal silicides, and the like. The reinforced layer of the nickel-based alloy has higher rigidity (HRC43-49) and excellent properties for anti-heat and shock and can be used for preparation the alloy reinforced layer on the seal surface of the stainless steel which has strict demands on the alloy components (B and Co are excluded).

Owner:有研金属复材技术有限公司

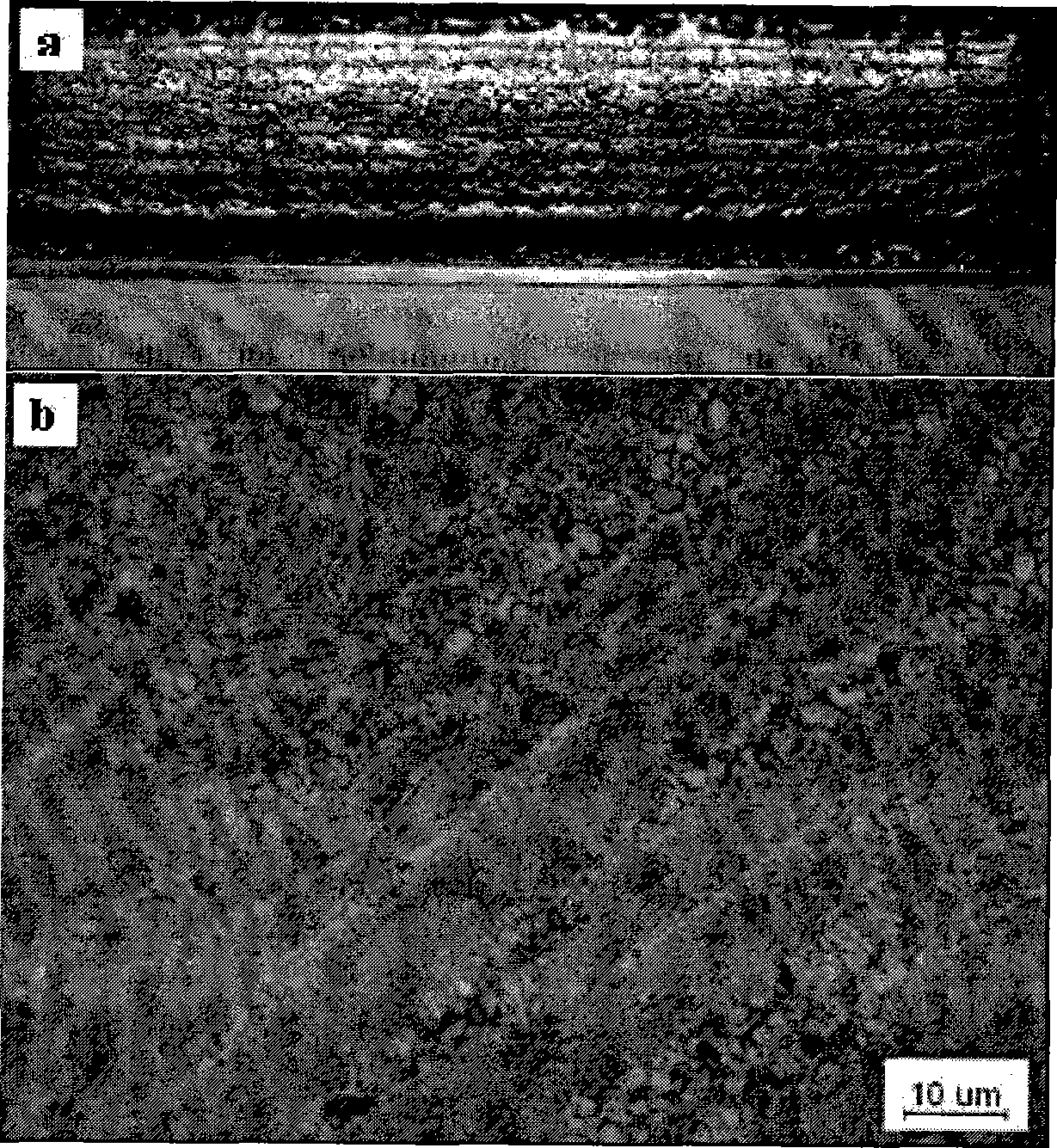

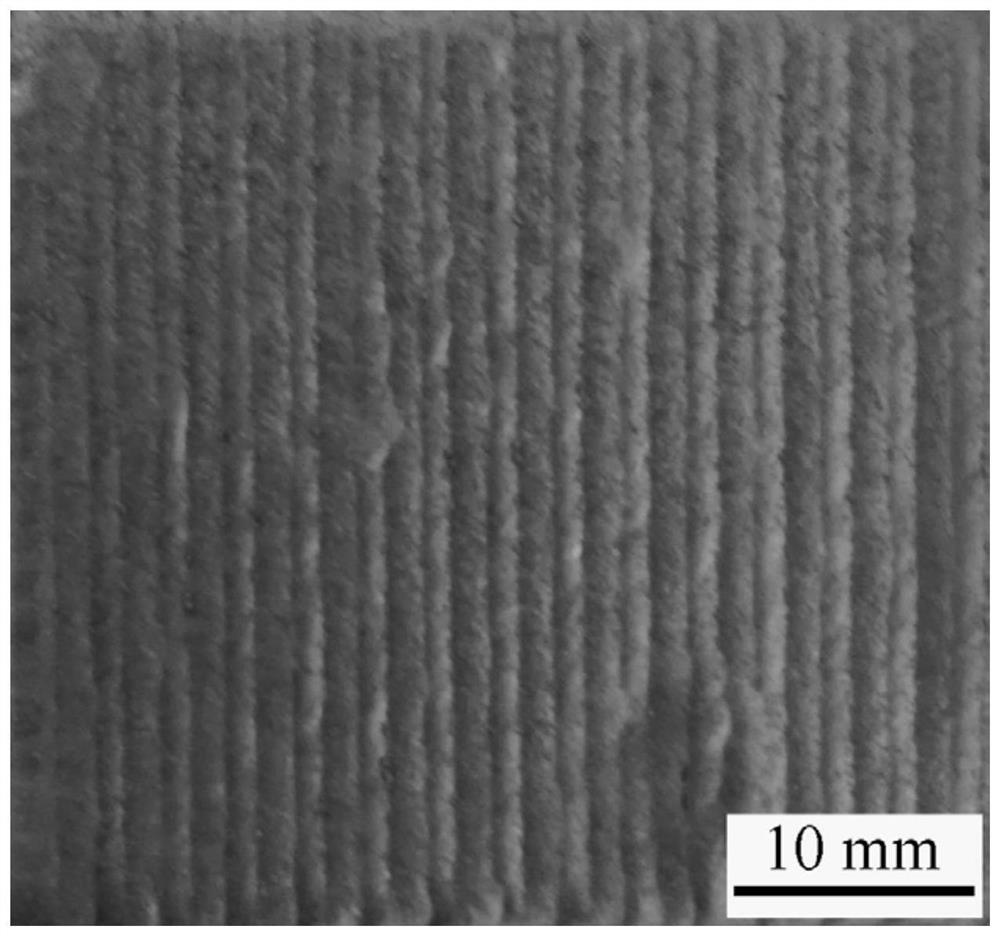

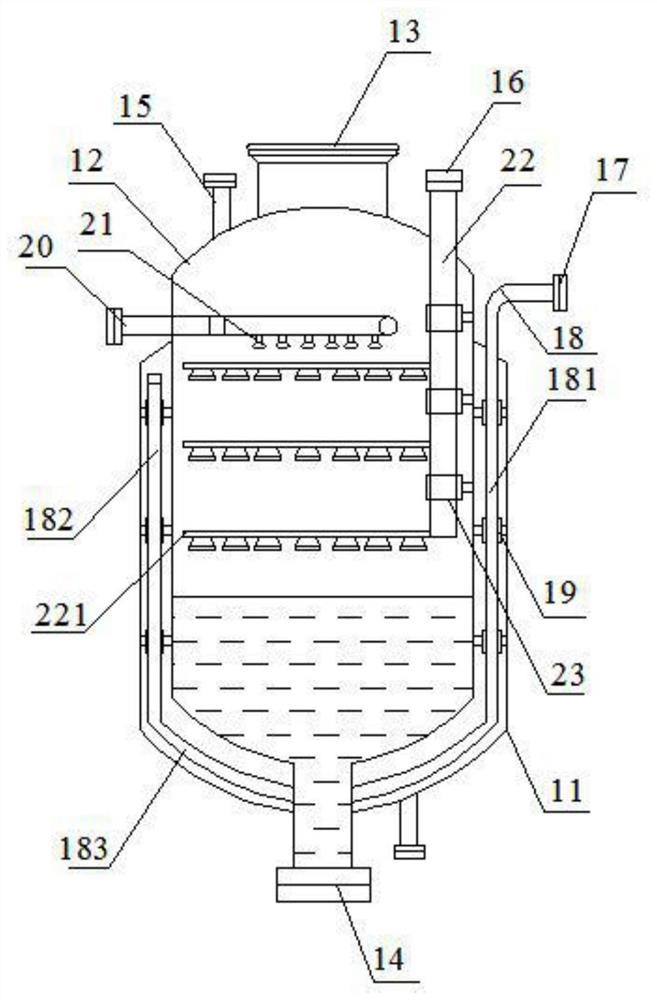

Method for preparing air inlet edge surface wear-resistant anti-corrosion alloy coating of tail stage blade of steam turbine

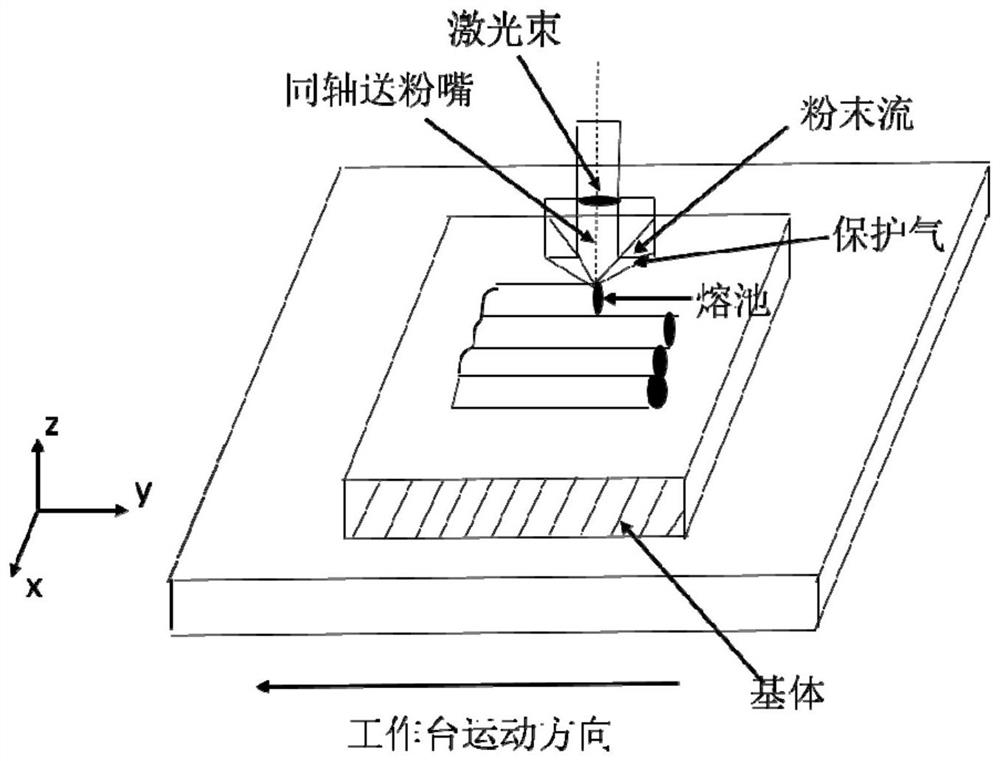

InactiveCN102453896AMelting fastFreeze fastMetallic material coating processesNumerical controlEdge surface

The invention relates to a method for preparing an air inlet edge surface wear-resistant anti-corrosion alloy coating of a tail stage blade of a steam turbine. The method is characterized by comprising the following steps that: 1) the air inlet edge surface of the tail stage blade of the steam turbine is pre-treated; 2) alloy powder is selected, and an automatic powder conveyor is regulated; 3) light beams are regulated; 4) the wear-resistant anti-corrosion coating laser cladding is carried out, a DL-HL-T5000 type CO2 laser is adopted, a work table is a SIMENS numerical control laser processing machine, a synchronous powder conveyor is adopted for conveying the alloy powder into a laser molten pool, high-power focus laser beams and an automatic powder conveying head are fed in the specified direction of the air inlet edge surface of the blade, and uniform and compact laser cladding layers are formed on the blade surface through processing; and 5) flaw detection is carried out after the cladding. According to the method, the laser cladding is adopted for uniformly cladding the alloy powder with the wear-resistant anti-corrosion performance onto the blade of the steam turbine, the uniform and compact metallurgical combining coatings are formed, the anti-corrosion performance reaches the stainless steel level, the cladding layer and a substrate form firm metallurgical combination, and the peeling is not easy to occur.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

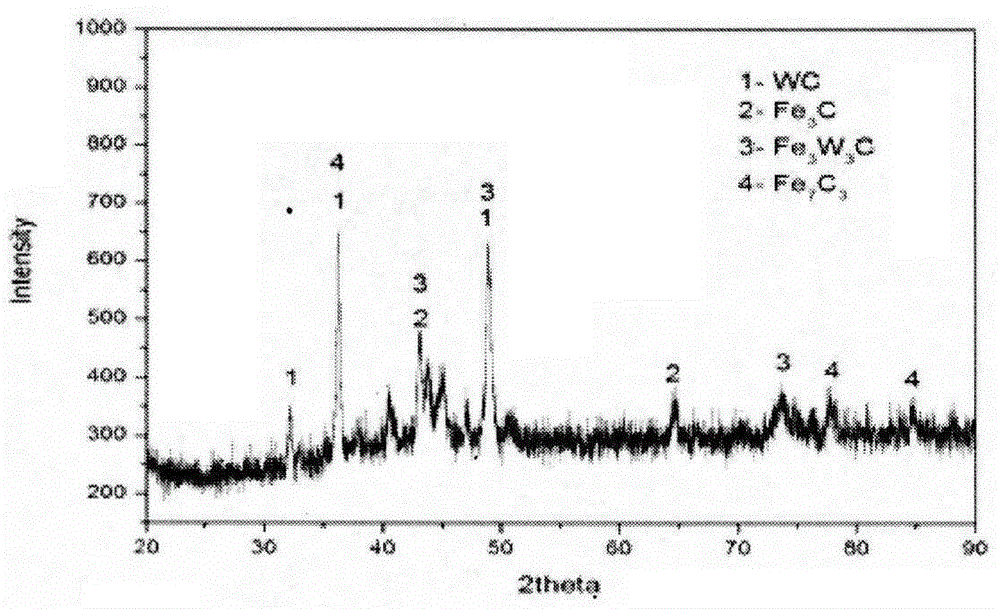

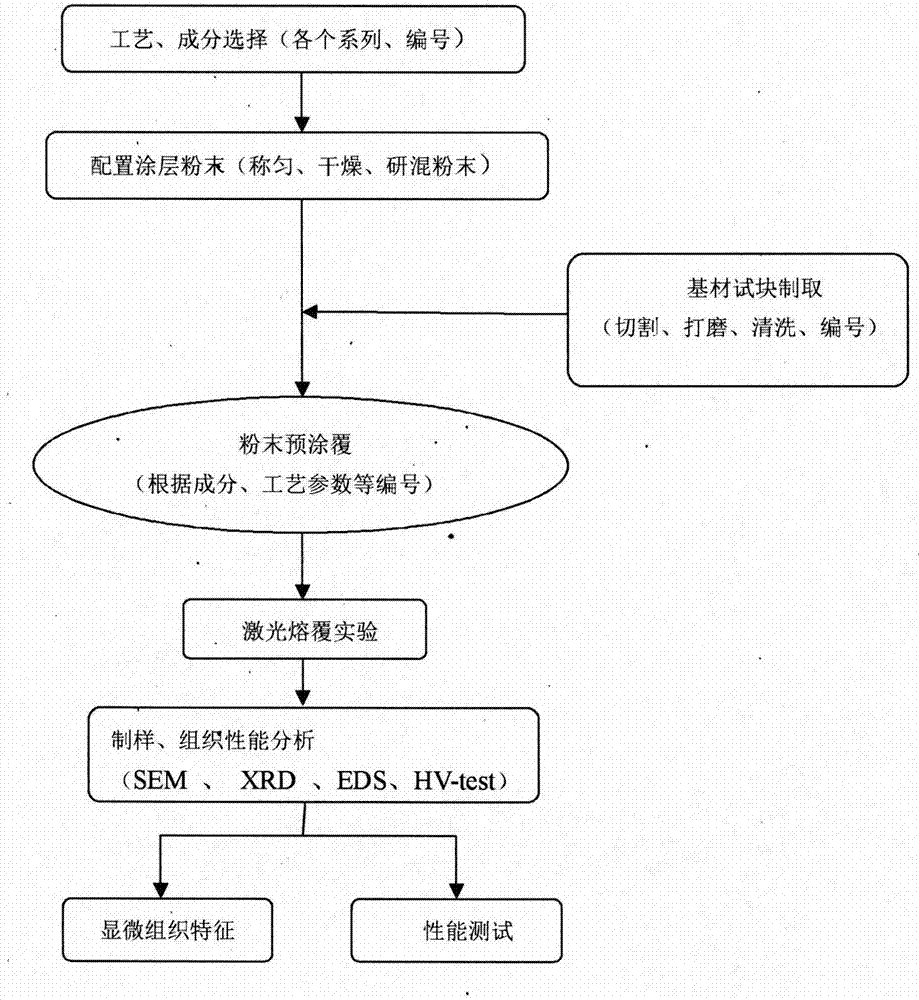

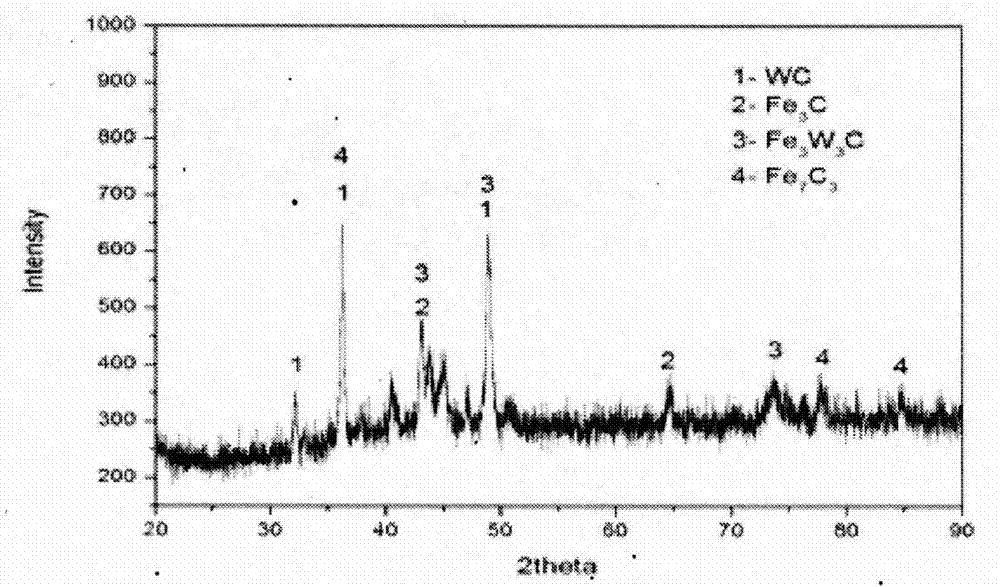

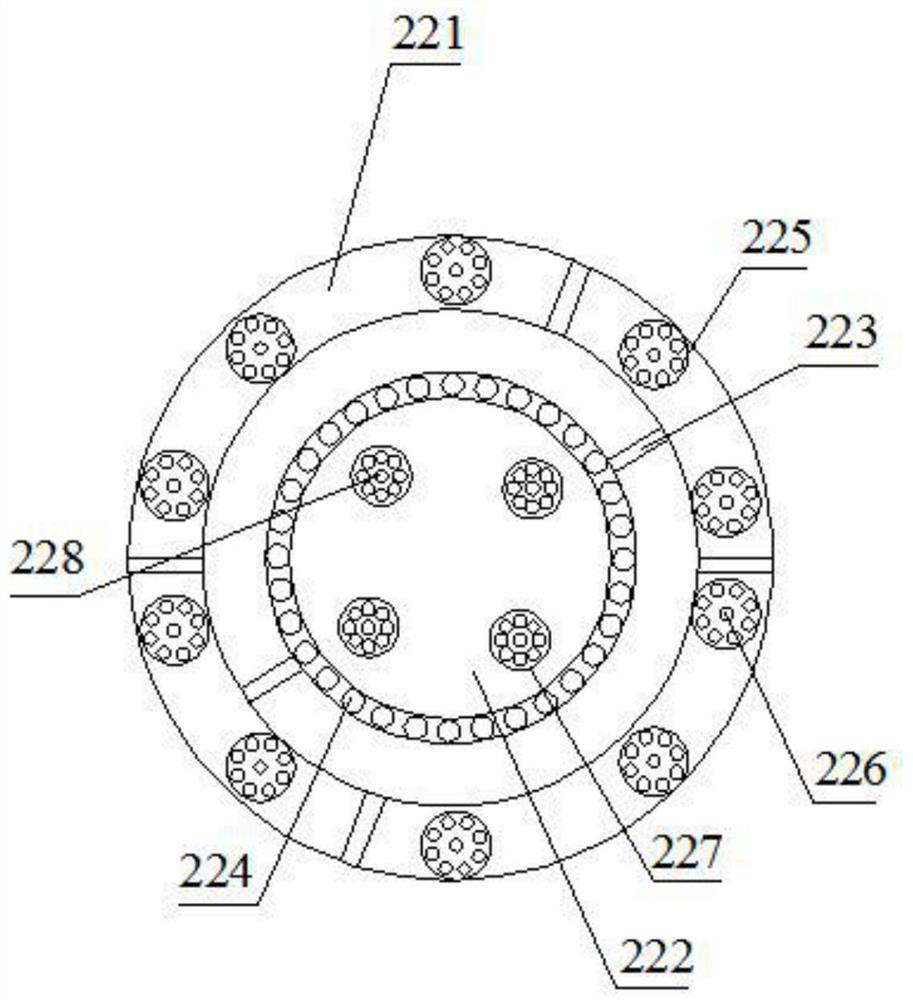

Laser-cladding tungsten carbide ceramic particle reinforced metal-based coating and processing method thereof

ActiveCN105112908AImprove bindingImprove wettabilityMetallic material coating processesAlloyMetallic Nickel

The invention discloses a laser-cladding tungsten carbide ceramic particle reinforced metal-based coating. The coating comprises alloy powder; the alloy powder comprises tungsten powder and graphite with the mole ratio of 2:1 and further comprises reduced iron powder, chromium powder, nickel powder, boron powder, silicon powder and copper powder; further, the alloy powder preferentially comprises the following components in percentage by mass: 55-60% of tungsten powder, 7-9% of graphite, 23-30% of reduced iron powder, 0-3% of chromium powder, 2-6% of nickel powder, 0.3-1% of boron powder and 0.4-1% of silicon powder. The invention further discloses a processing method for the laser-cladding tungsten carbide ceramic particle reinforced metal-based coating. According to the invention, a tungsten carbide particle reinforcing phase for reinforcing the iron-based composite is successfully prepared through a laser cladding in-situ synthesis technology, and a transition layer is arranged between the coating and the matrix, so that atom binding between the coating and the matrix is realized and the bonding strength is relatively high.

Owner:WENZHOU UNIVERSITY

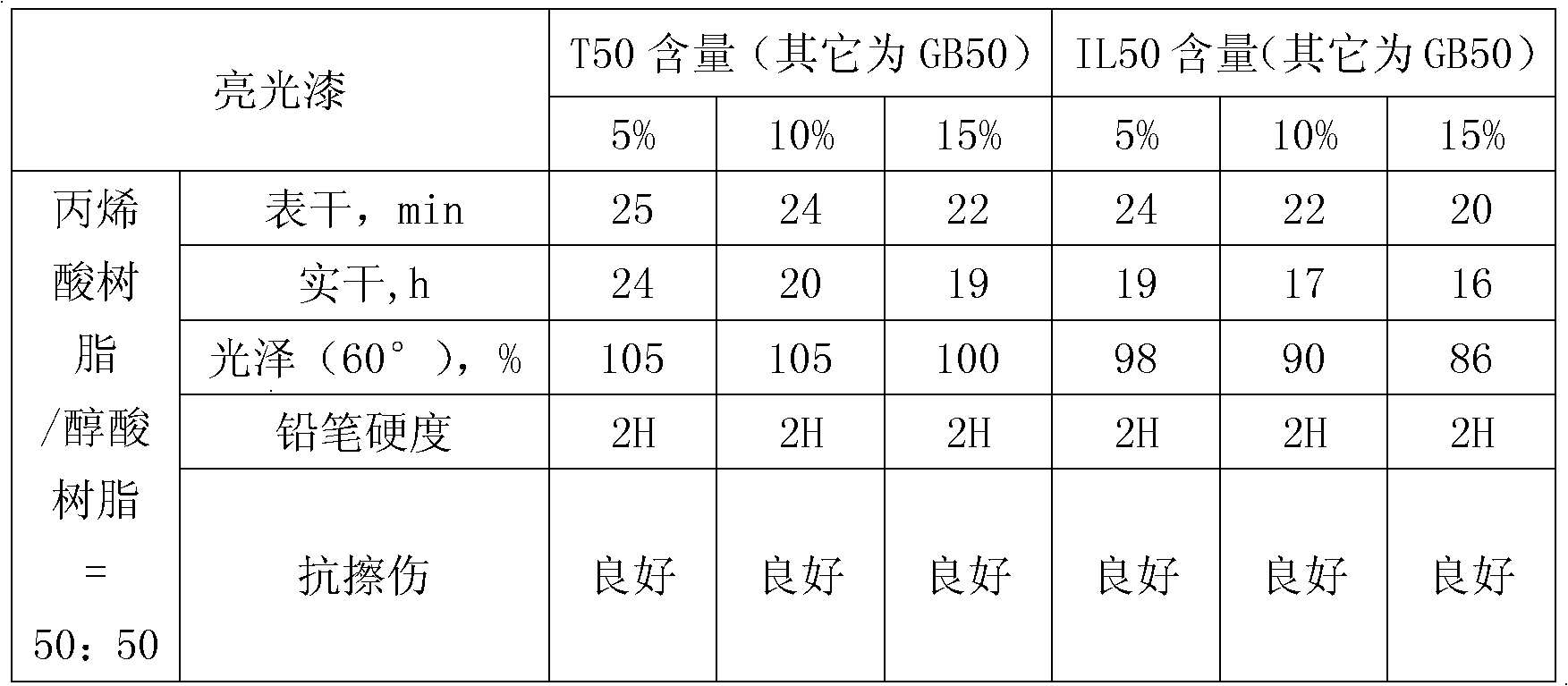

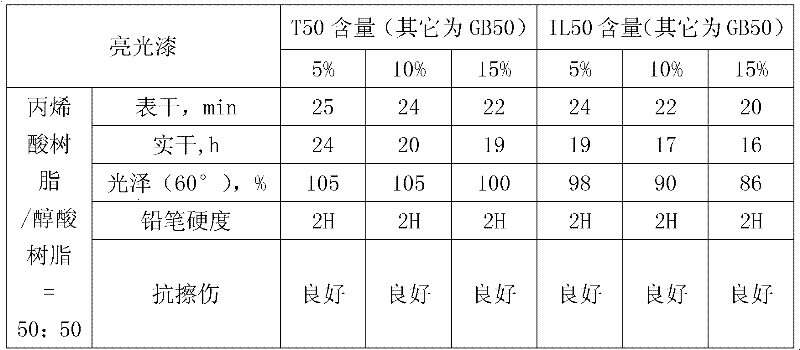

Poly-isocyanurate polyurethane coating curing agent and preparation method thereof

ActiveCN102115525AGood compatibilitySimple production processPolyurea/polyurethane coatingsChemical structureWeather resistance

The invention relates to a poly-isocyanurate polyurethane coating curing agent and a preparation method thereof. The curing agent is isozyanurat ring-containing structure and polyurethane prepolymer solution of which end is sealed by NCO group by the means that isozyanurat-based polyether glycol is reacted with polyisocyanate in acetate dissolvants, and polymerization inhibitor is further added into the solution. The curing agent has the chemical structure which is similar to isocyanate tripolymer curing agent; the curing agent is low in viscosity, good in storing stability, and low in cost; and the hydroxy acrylic resin and the alkyd resin are good in consistency. The prepared film has the characteristics of being good in adhesive force, flexibility, thermostability, weather resistance and corrosion resistance, high in hardness and the like, thereby being applicable to the high-grade field of vehicle painting.

Owner:SHANDONG INOV POLYURETHANE

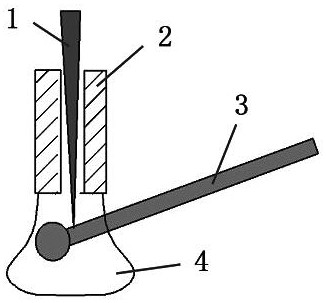

High-efficient wire material laser cladding method

InactiveCN109434286AImprove cladding efficiencyIncreased cladding line speedLaser beam welding apparatusLaser beamsMelting point

The invention provides a wire material laser cladding method. The wire material laser cladding method comprises the following steps that one electrode of a wire material heating device is connected with a workpiece, the other electrode of the wire material heating device is connected with a conductive nozzle, the wire material penetrates through the conductive nozzle and then makes contact with the surface of the workpiece, a laser beam and the wire material are placed in a certain angle with the surface of the workpiece respectively, the wire material heating device is started, the wire material is preheated to a certain temperature, a laser is started, and a laser beam generated by the laser is focused on wire material on the surface the workpiece, the laser energy is absorbed by the wire material, then a molten pool is instantly formed on the surface of the workpiece, the melting pool is controlled to move on the surface of the workpiece according to a preset path and a preset speed, and the laser cladding is completed. According to the method, the initial temperature and the cladding linear speed of the wire material are increased, the temperature of the wire material is increased to be close to the melting point before the wire material enters the laser beam, the wire material can melt to form a molten pool on the surface of the workpiece only by relatively small laser energy and relatively short irradiation time of the laser beam, and the wire cladding efficiency and quality are obviously improved, therefore the method has a wide popularization and application prospect.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

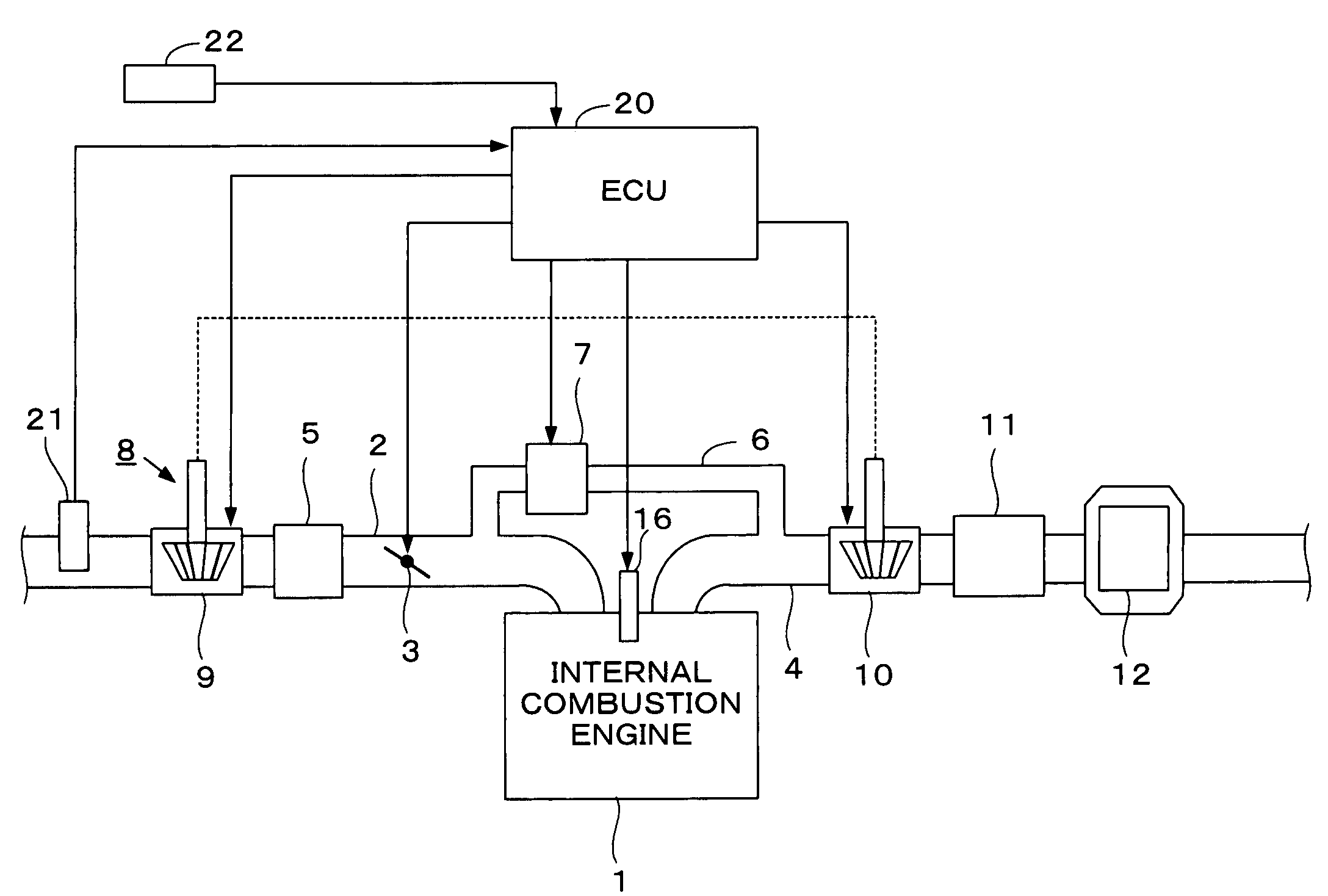

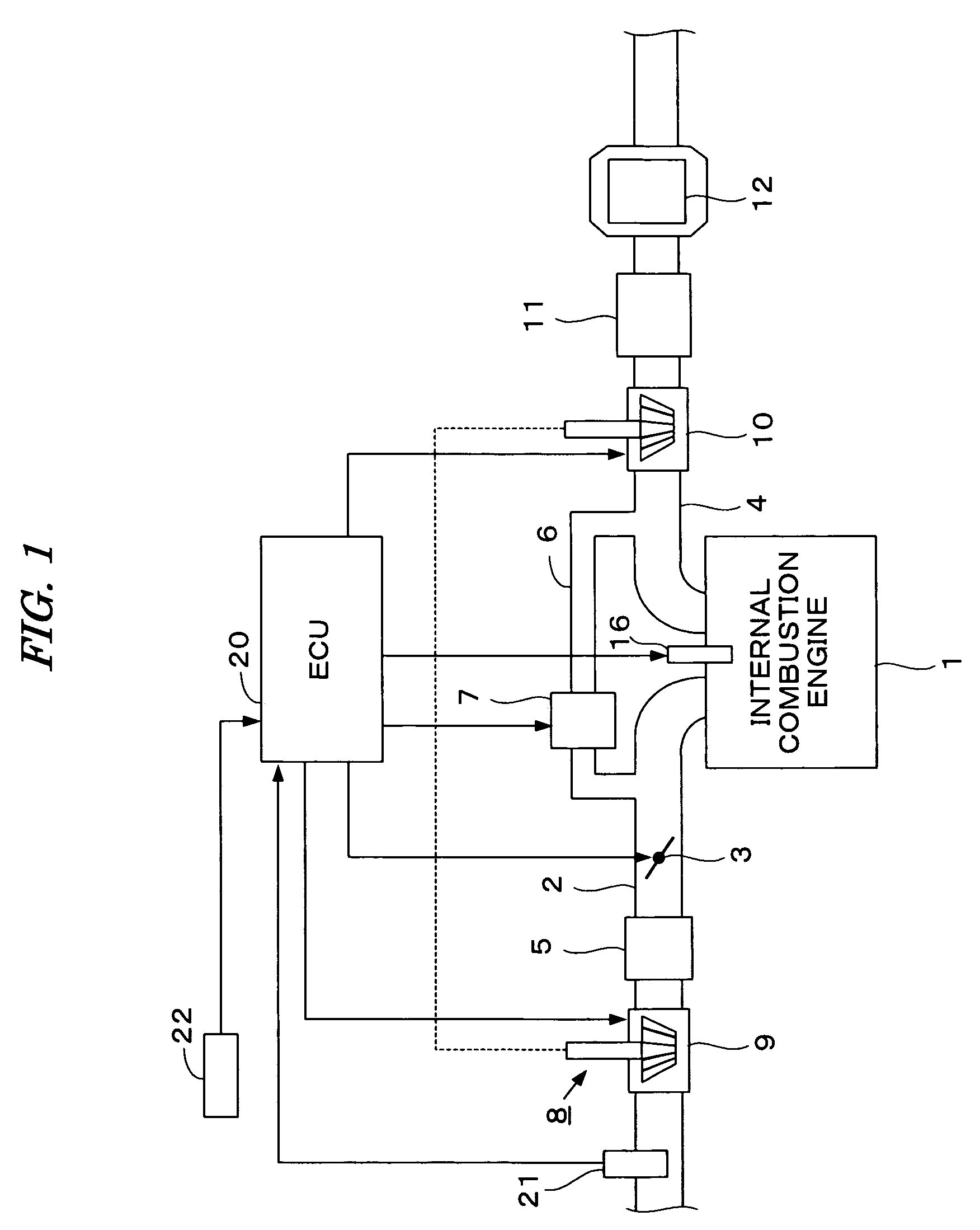

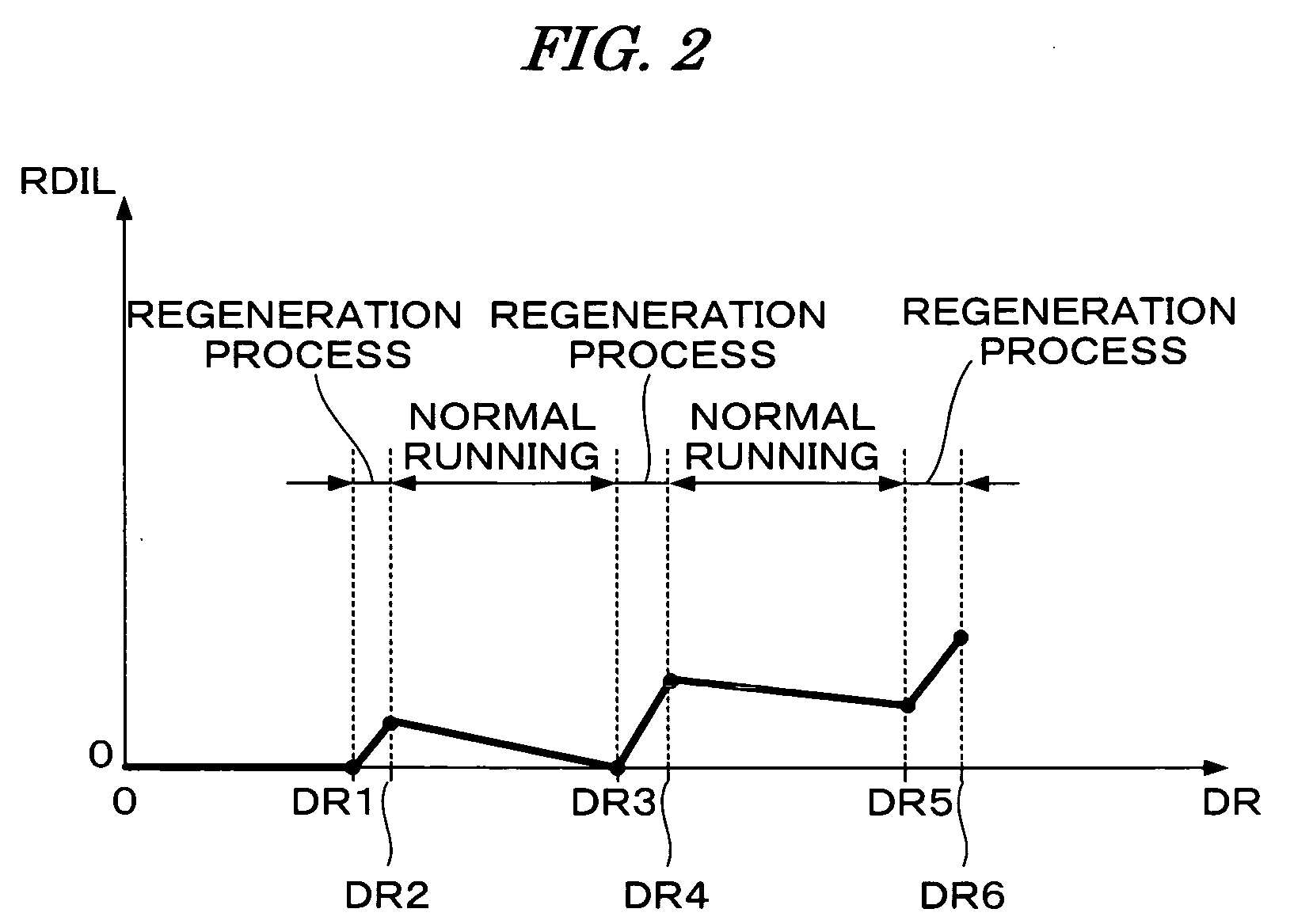

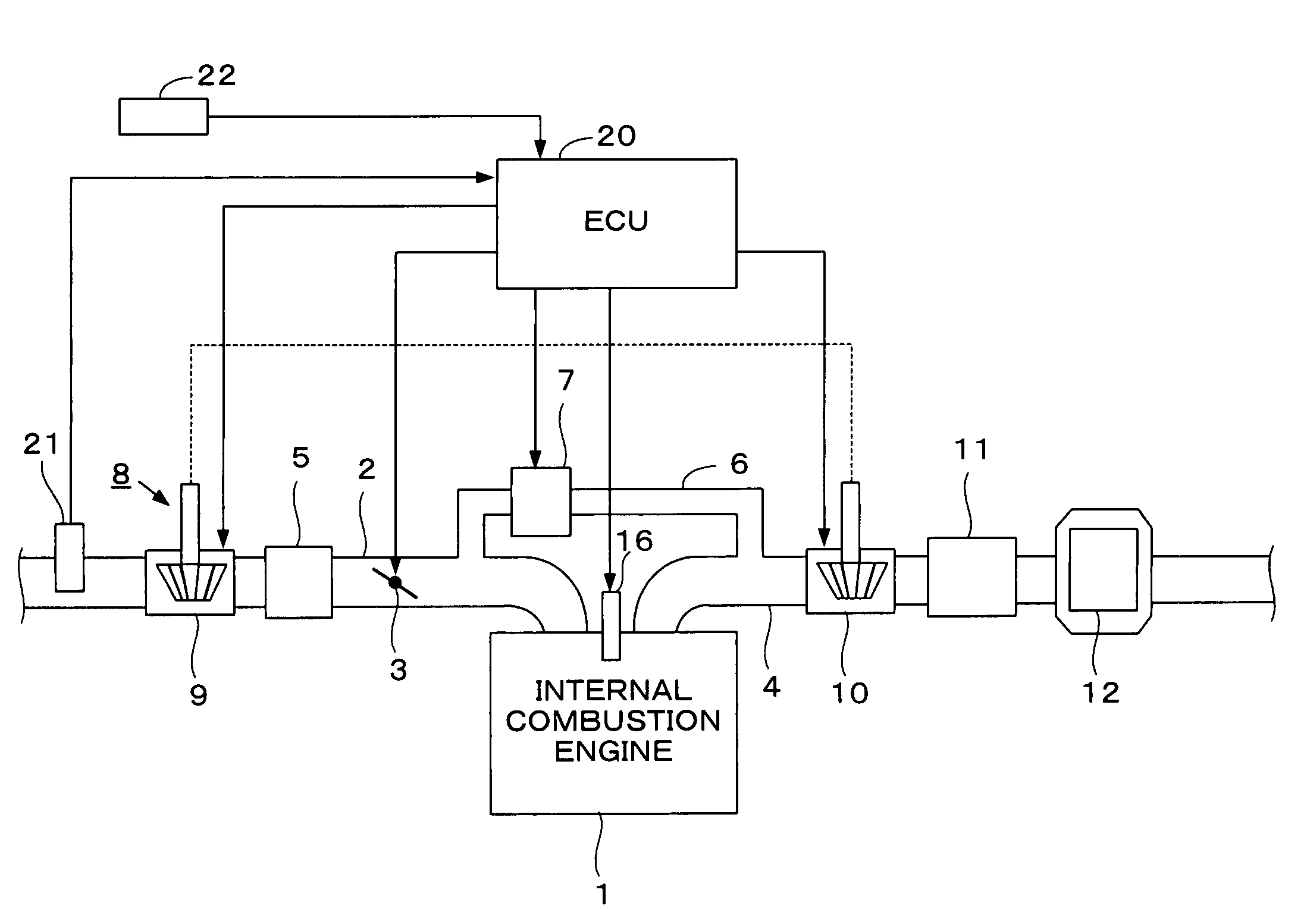

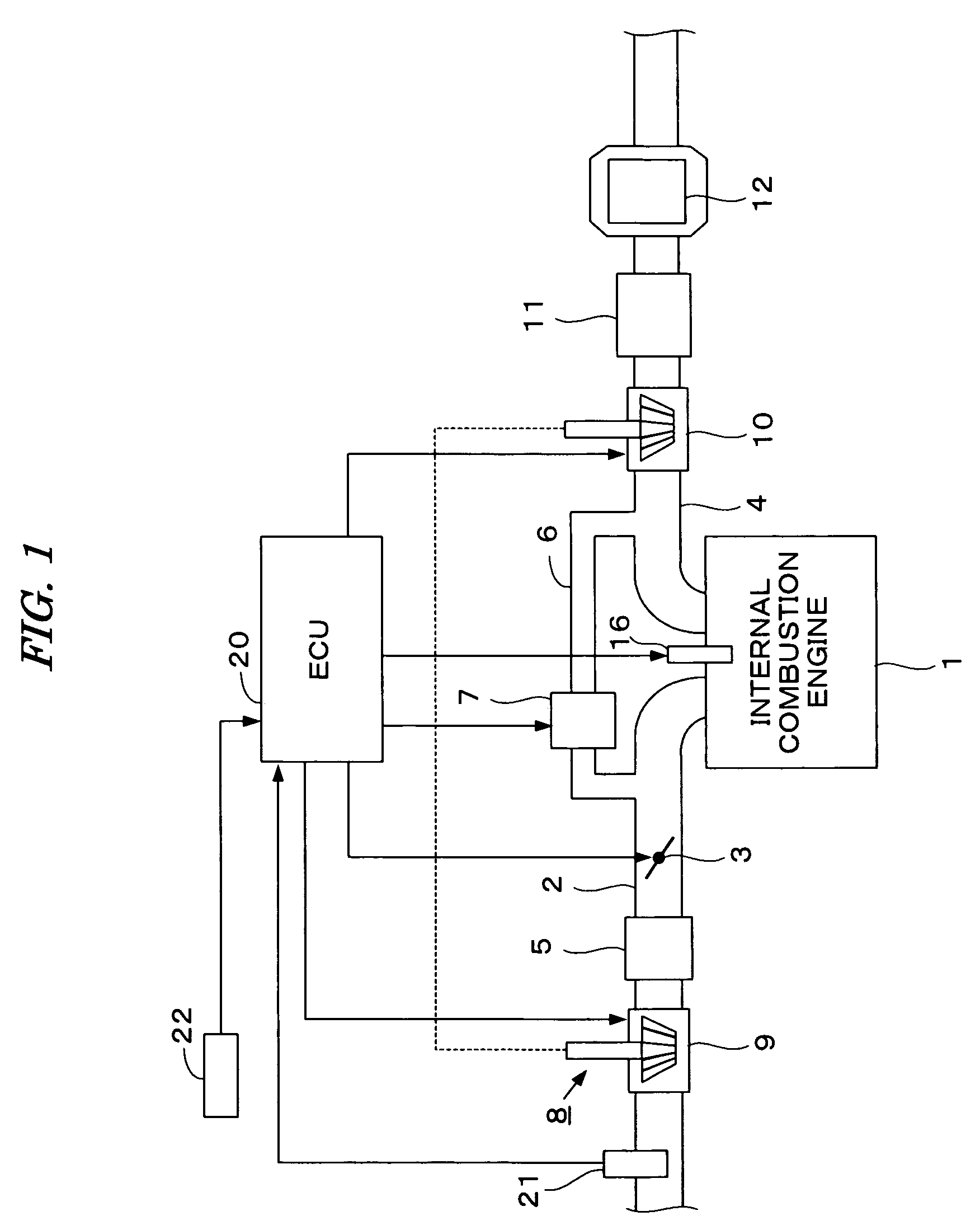

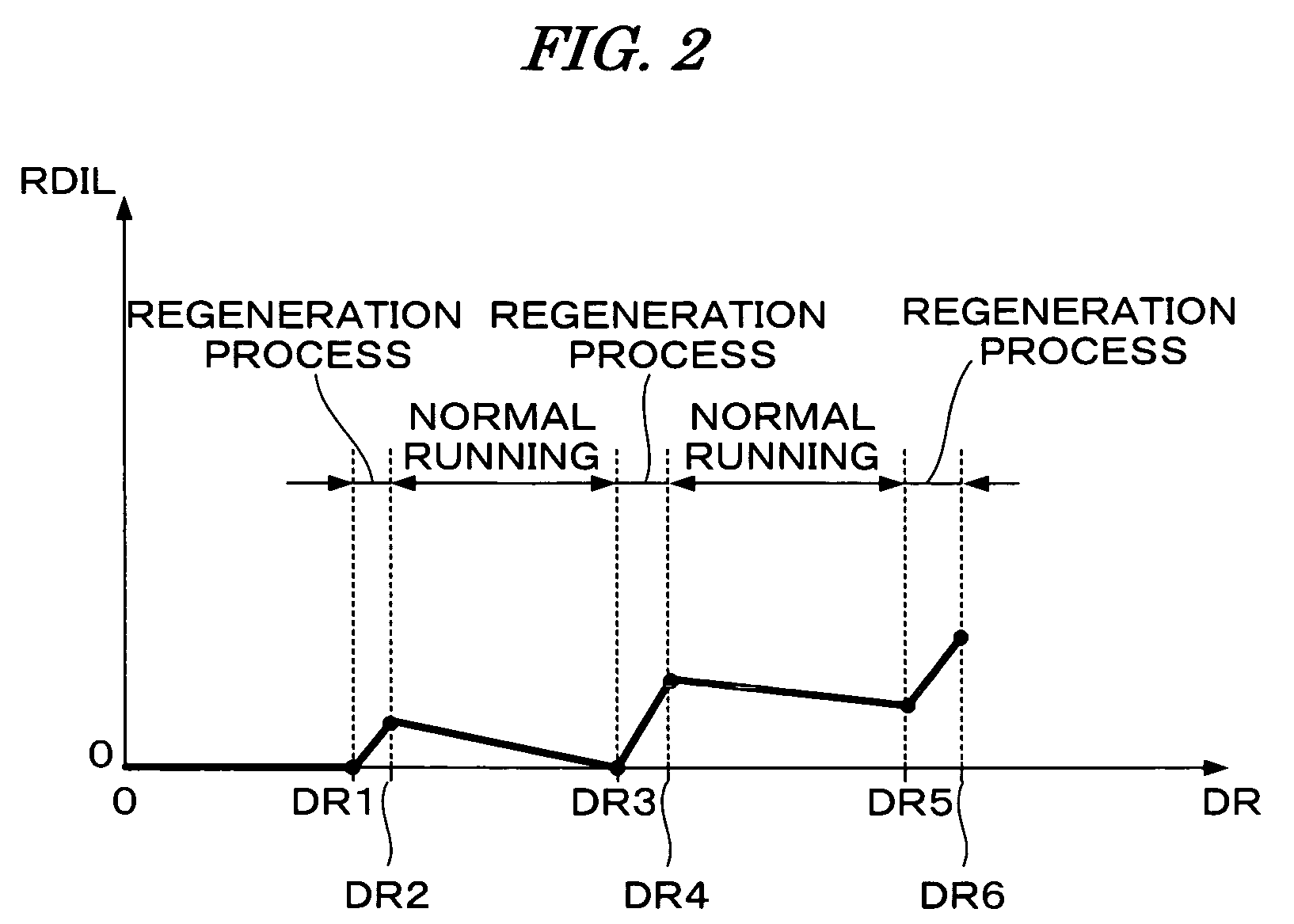

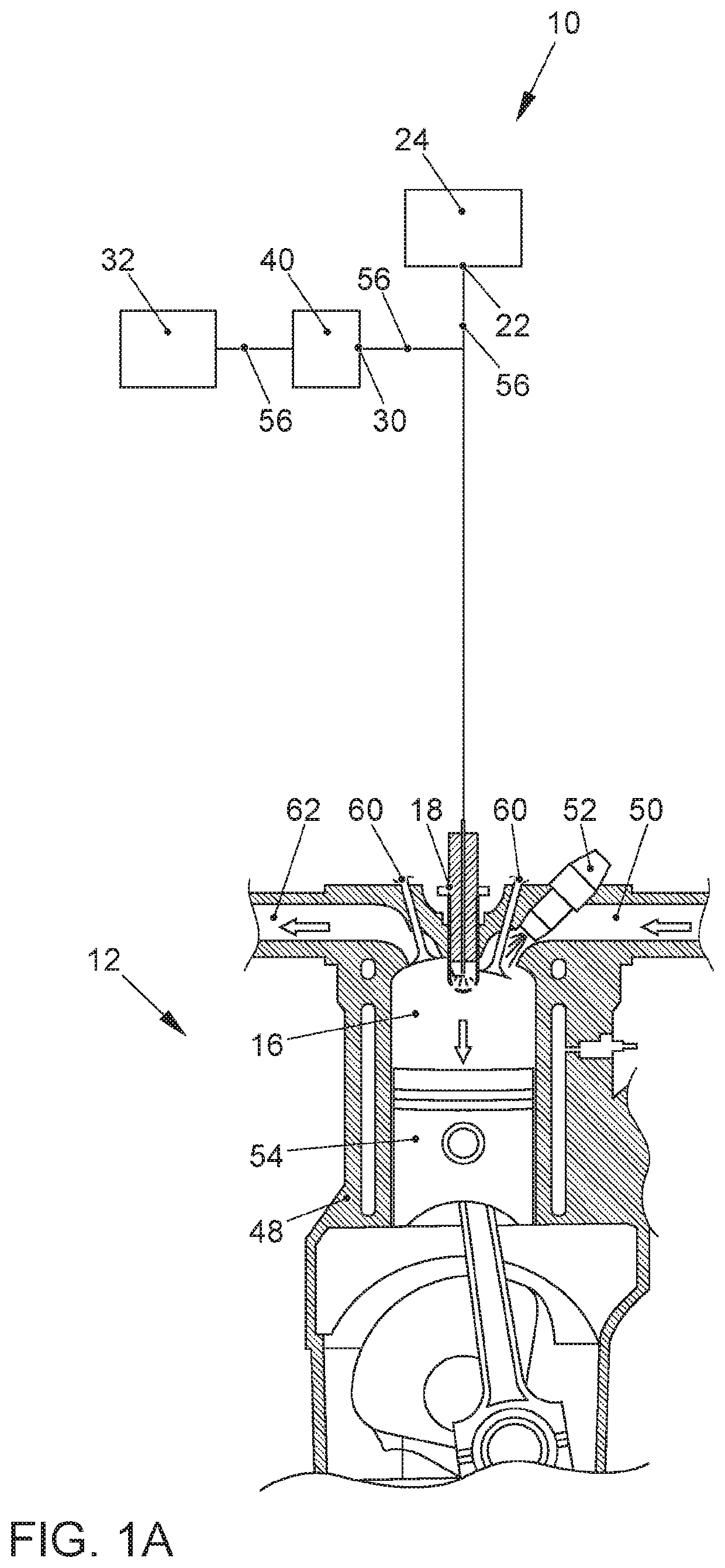

Exhaust gas purifying apparatus for internal combustion engine

InactiveUS20060254262A1Avoid dilutionSuppressing any increaseAnalogue computers for vehiclesCombination devicesParticulatesExhaust fumes

An exhaust gas purifying apparatus for an internal combustion engine includes a particulate filter for trapping particulates found in the exhaust gases of the engine. The regeneration process for burning the particulates trapped in the particulate filter is executed by performing post injection of fuel. The regeneration process is suppressed according to an amount of fuel injected during post injection.

Owner:HONDA MOTOR CO LTD

Low carbon hydrate beer and manufacturing method thereof

The invention relates to low carbohydrate beer, which comprises water, alcohol, carbohydrate, protein, carbon dioxide, mineral composition and other compositions, wherein, the carbohydrate is equal to or less than 1.6 percent (m / m), and the heat is equal to or less than 108KJ / 100ml. The manufacturing method of the beer is that: crushing malt, carrying out saccharification and fermentation, filtering and packaging, wherein, the selected raw material is two-rowed malt; the saccharification temperature is 62-65 DEG C and the saccharification time is 60-100 minutes, efficient enzyme preparation is added in the process of saccharification, thereby the fermentation degree of the beer reaches a higher value; maltogenic amylase and pullulanase can be separately selected or selected in a blending way as the efficient enzyme preparation. Compared with the traditional beer, the carbohydrate of the beer is reduced by more than 56 percent, the heat is reduced by more than 36 percent, the rate of dilution can be enlarged to 70 percent, and the main fermentation time is shortened, thereby reducing grain consumption, improving production efficiency, saving production cost and improving product quality.

Owner:TSINGTAO BREWERY

Exhaust gas purifying apparatus for internal combustion engine

InactiveUS7611567B2Avoid dilutionSuppressing any increaseCombination devicesAnalogue computers for vehiclesExternal combustion engineExhaust fumes

An exhaust gas purifying apparatus for an internal combustion engine includes a particulate filter for trapping particulates found in the exhaust gases of the engine. The regeneration process for burning the particulates trapped in the particulate filter is executed by performing post injection of fuel. The regeneration process is suppressed according to an amount of fuel injected during post injection.

Owner:HONDA MOTOR CO LTD

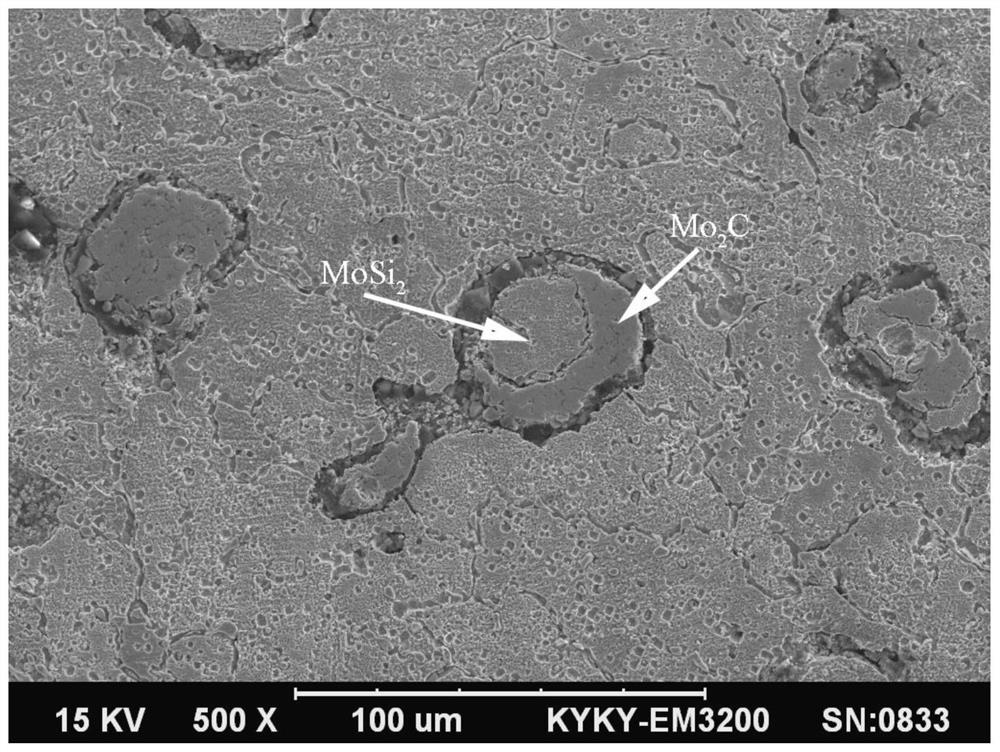

Preparation method of laser cladding in-situ synthesis ceramic phase reinforced copper-based cladding layer

ActiveCN112281157ADense tissueNo crackIncreasing energy efficiencyMetallic material coating processesCrazingMetallurgy

The invention discloses a preparation method of a laser cladding in-situ synthesis ceramic phase reinforced copper-based cladding layer. The preparation method comprises the following steps that S1, substrate pretreatment is carried out, specifically, a pure copper substrate is placed on the working surface, abrasive paper polishing, oil removing, rust removing and cleaning are carried out, and then blackening treatment is carried out; S2, cladding powder is prepared, specifically, the cladding powder containing Mo powder, SiC powder, Ni powder and Cu powder is prepared, wherein the content ofMo and SiC accounts for 10 wt.%-30 wt.%, the content of Ni powder accounts for 30 wt.%-40 wt%, and the balance is Cu powder; Mo accounts for 85.67 wt.%, and SiC accounts for 14.33 wt.%; S3, powder mixing and drying are carried out, specifically, the cladding powder prepared in the step S2 is mixed through a V-shaped mixer, and then the mixed powder is dried; and S4, laser cladding is carried out,specifically, the laser cladding is carried out under the protective gas atmosphere, and the multiphase ceramic is generated. The ceramic phase reinforced copper-based cladding layer prepared by themethod is compact in structure and free of pores and cracks, and has a good application prospect.

Owner:YANSHAN UNIV

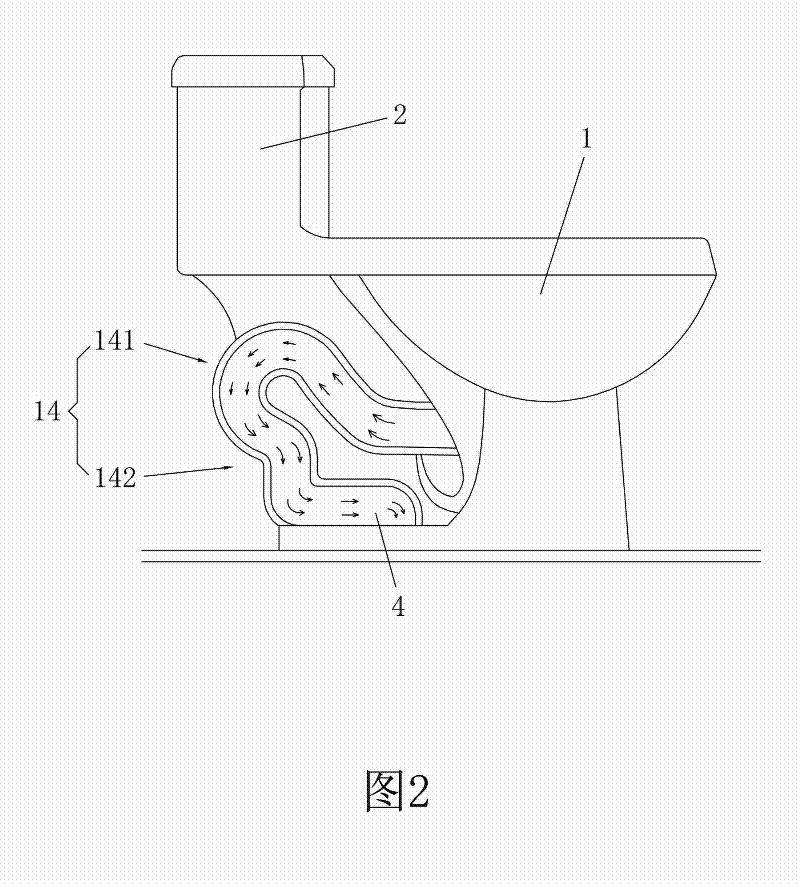

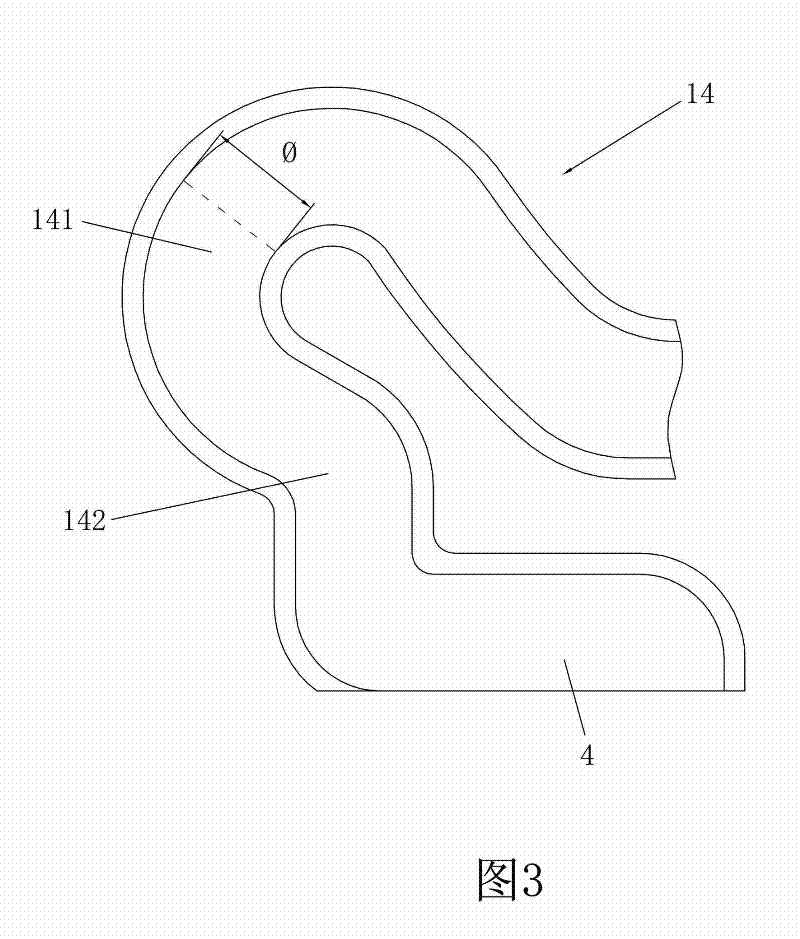

Water-saving siphon type one-piece pedestal pan

InactiveCN102251570ASmall water lossStrong waterWater closetsFlushing devicesEngineeringFlush toilet

The invention relates to a water-saving siphon type one-piece pedestal pan comprising an integrated flush toilet body and a water tank, wherein auxiliary water channels and a siphon bend are arranged on the flush toilet body. The water-saving siphon type one-piece pedestal pan is characterized in that a laterally inversed V-shaped folding part extending out of the upper part inside a pipe cavity is arranged in the middle of an outer side pipe wall of a small S bend of the siphon bend; a left auxiliary water channel and a right auxiliary water channel are symmetrically arranged at two sides ofthe back part of the flush toilet body, the upper ends of the left auxiliary water channel and the right auxiliary water channel are communicated with the water tank; and the lower ends of the left auxiliary water channel and the right auxiliary water channel are respectively communicated with a sewage draining opening of the flush toilet body through a connecting water channel arranged around the sewage draining opening of the flush toilet body. A double-flushing type injection pipe with a large flushing force and a favorable direct wash-down effect is formed by the left auxiliary water channel and the right auxiliary water channel; a hopper section is formed between the folding part of the siphon bend and a necking down part; the pipe diameter of the siphon bend above the folding part can be increased to 45-50mm; the hopper section is arranged to match with a big S bend of a big pipe diameter, which ensures that early water passing through the folding part seals air and then enters the hopper section to form double water-sealing and ensures that big siphon is formed as soon as possible; only 41-42 L of water is needed, therefore, the water-saving effect is obvious; and the dilution rate reaches 100%, therefore, the flushing is thorough.

Owner:FUJIAN NANAN HUSHENG BUILDING MATERIALS

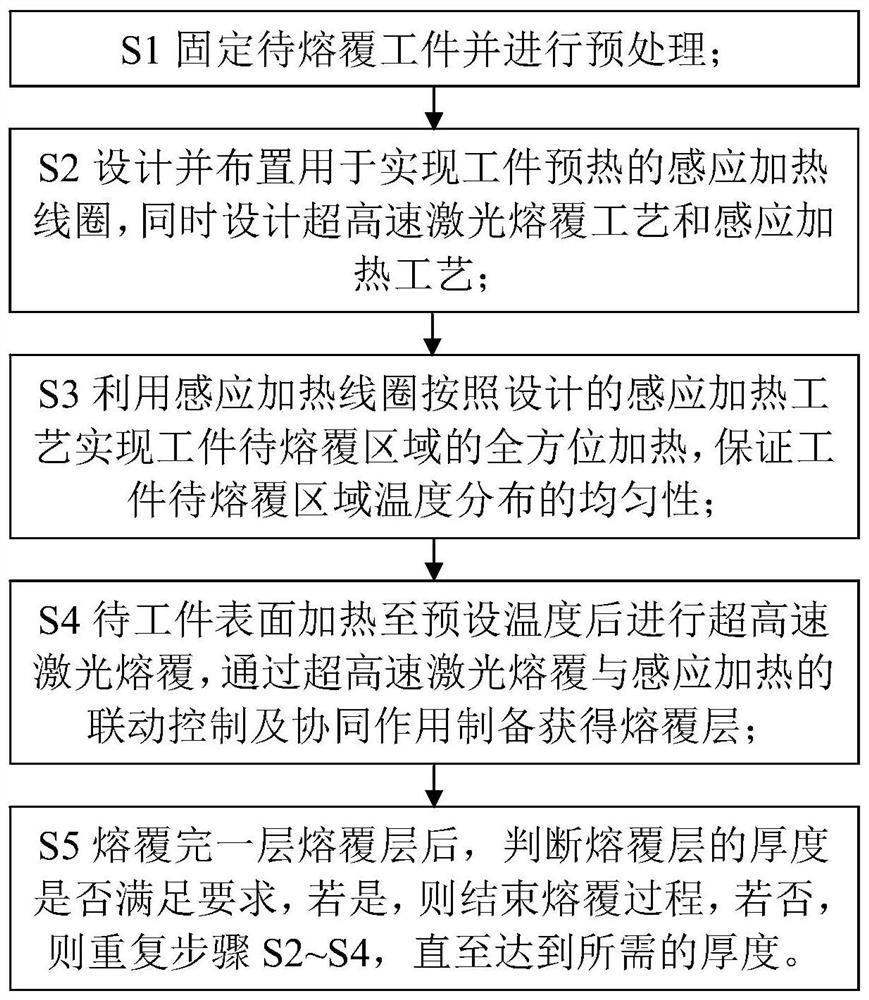

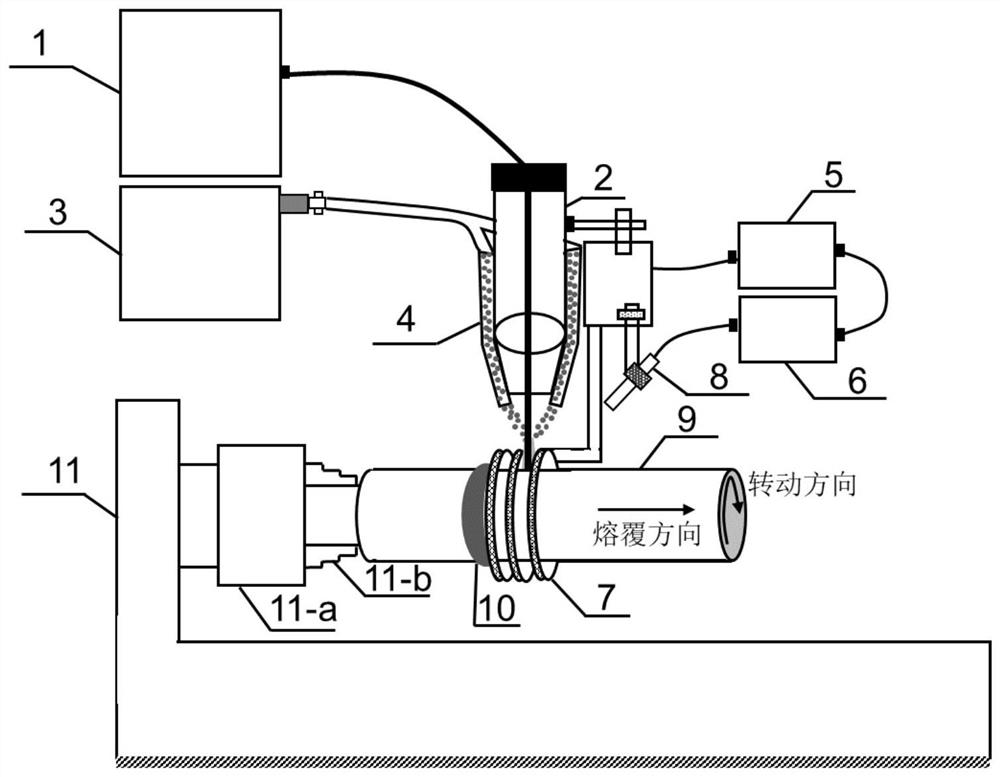

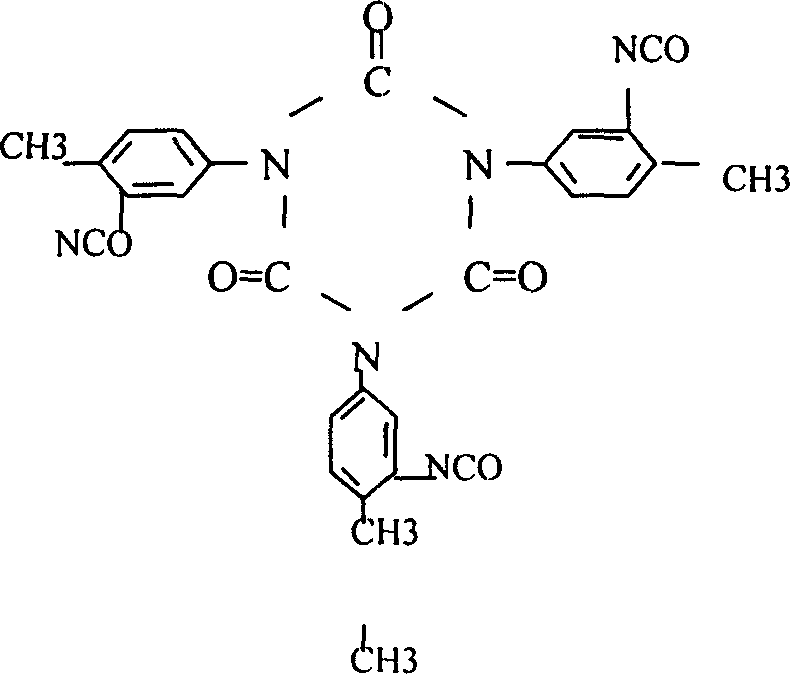

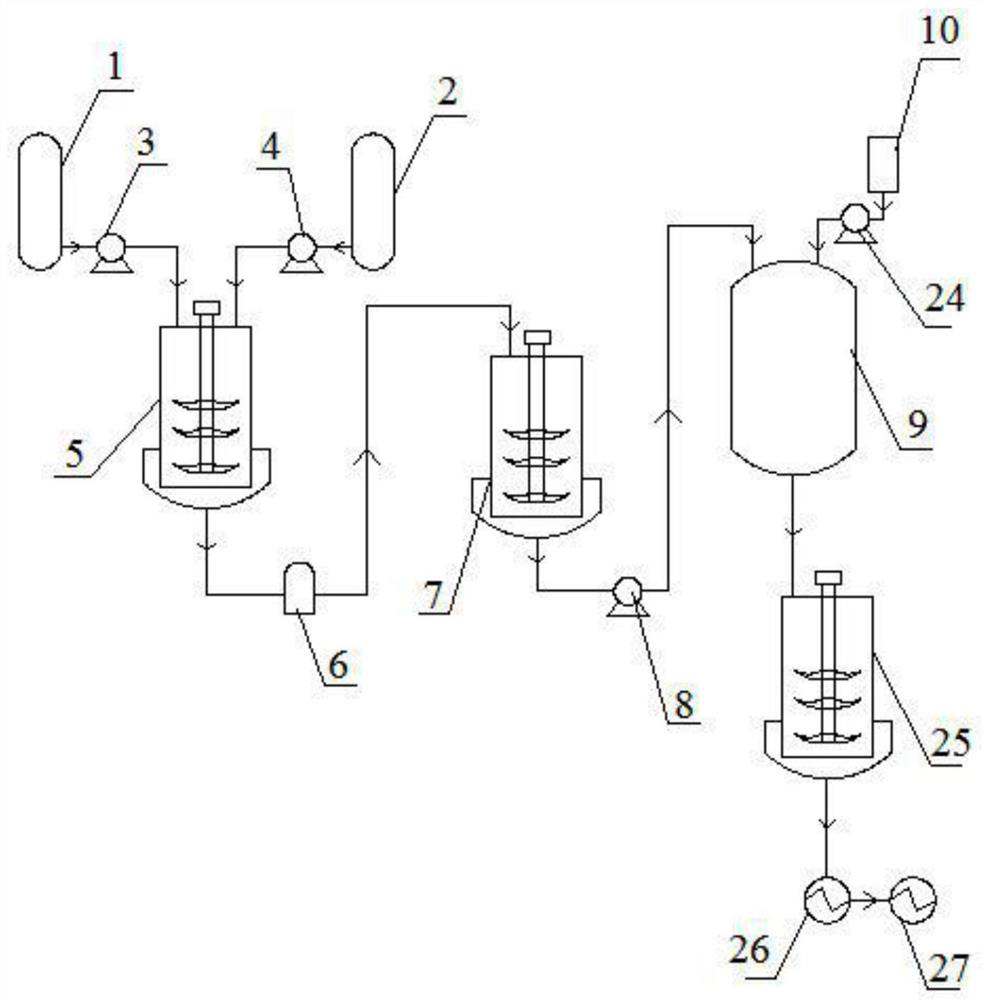

Ultrahigh-speed laser-induction composite cladding method and device

ActiveCN111676477AHigh precisionQuality improvementIncreasing energy efficiencyMetallic material coating processesUltra high speedAlloy

The invention belongs to the field of surface coating processing, and particularly discloses an ultrahigh-speed laser-induction composite cladding method and device. Aiming at a workpiece to be cladded as a processing object, the ultrahigh-speed laser-induction composite cladding device is provided with an induction heating coil used for realizing the fact of preheating the workpiece, the induction heating coil is arranged nearby the workpiece to be cladded, a area to be cladded of the workpiece is heated to a set temperature through the shape of the induction heating coil and the spatial arrangement of the induction heating coil relative to the workpiece to be cladded; and carrying out ultrahigh-speed laser-induction composite cladding above the area to be cladded of the workpiece by adopting ultrahigh-speed laser cladding and induction heating modes, so that interaction effect between a laser beam spot and a powder beam flow is carried out at a target position of a cladding area to heat a alloy powder to a molten drop or semi-molten drop state, and the alloy powder is sprayed to a micro molten pool on the preheated surface of the workpiece in a liquid or semi-solid form so as toprepare a required cladding layer. By means of the ultrahigh-speed laser-induction composite cladding method and device, high-precision, high-performance and metallurgical-defect-free ultra-efficientdeposition of the metal cladding layers of various materials can be achieved on the surface of a metal component.

Owner:武汉飞能达激光技术有限公司

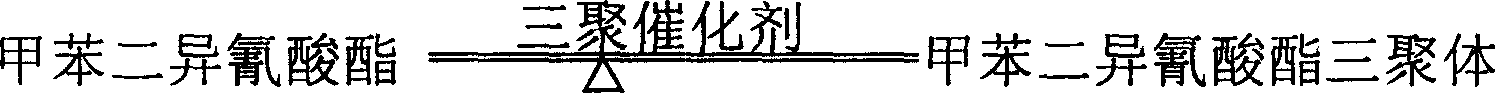

Preparation of dissolvable curing agent for tripolymer of toluene diisocyanate

InactiveCN1186405CWide applicabilitySolve the problem of slow drying in winterCoatingsToluene diisocyanateBoiling point

A high-compatibility trimer as solidifying agent for paint is prepared from toluene diisocyanate or its mixture, ester-type solvent aliphatic alcohol and isocyanate trimer catalyst through reacting between first three under protection of N2 at 30-80 deg.C for 1-6 hr while stirring, adding the last one, reacting, cooling to 50-100 deg.C, continuous reacting until the Wt pecentage of NCO is 7.4-8.4, and polymerizing inhititor, and cooling to lower than 40 deg.C.

Owner:ZHUHAI FEIYANG NOVEL MATERIALS

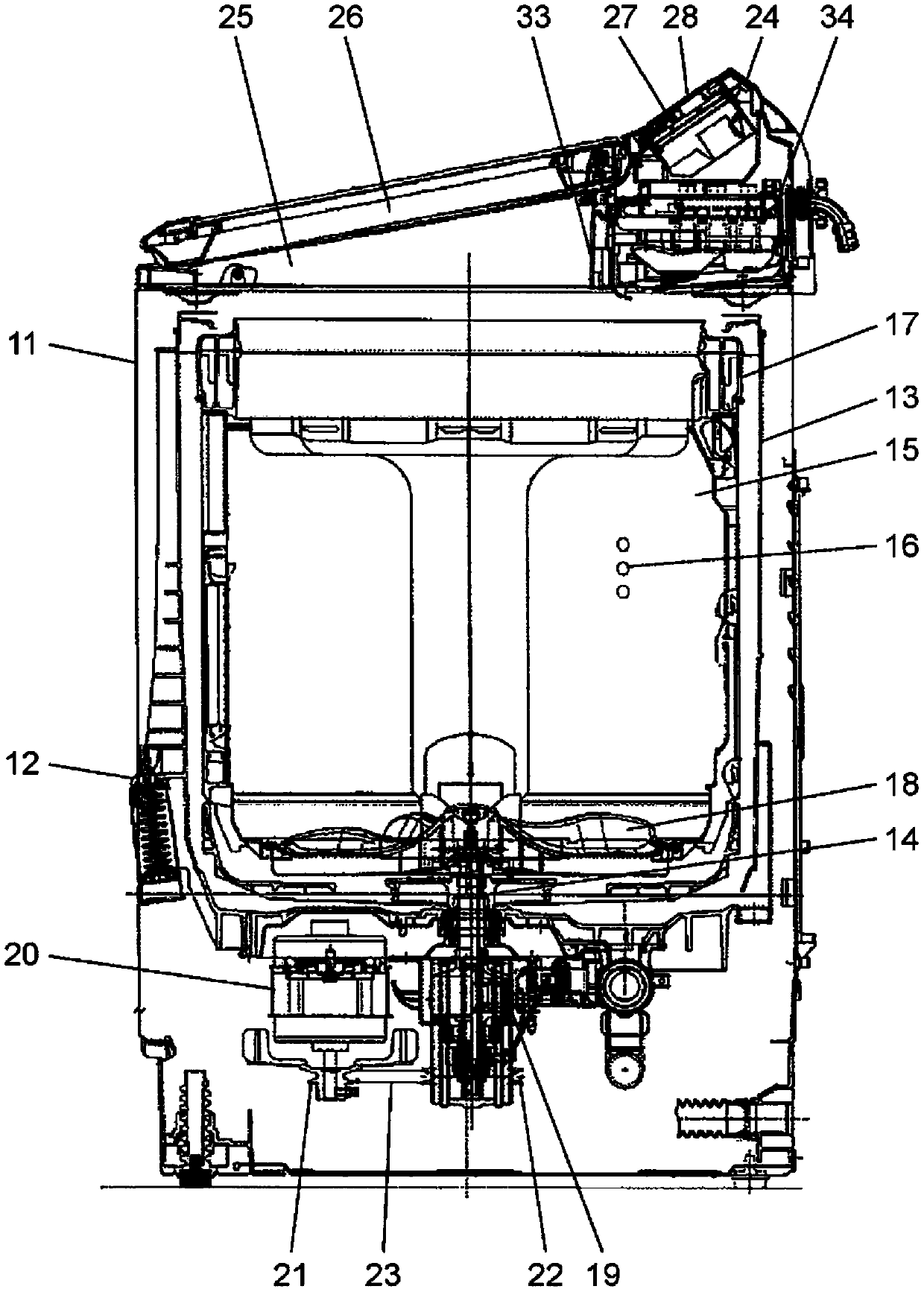

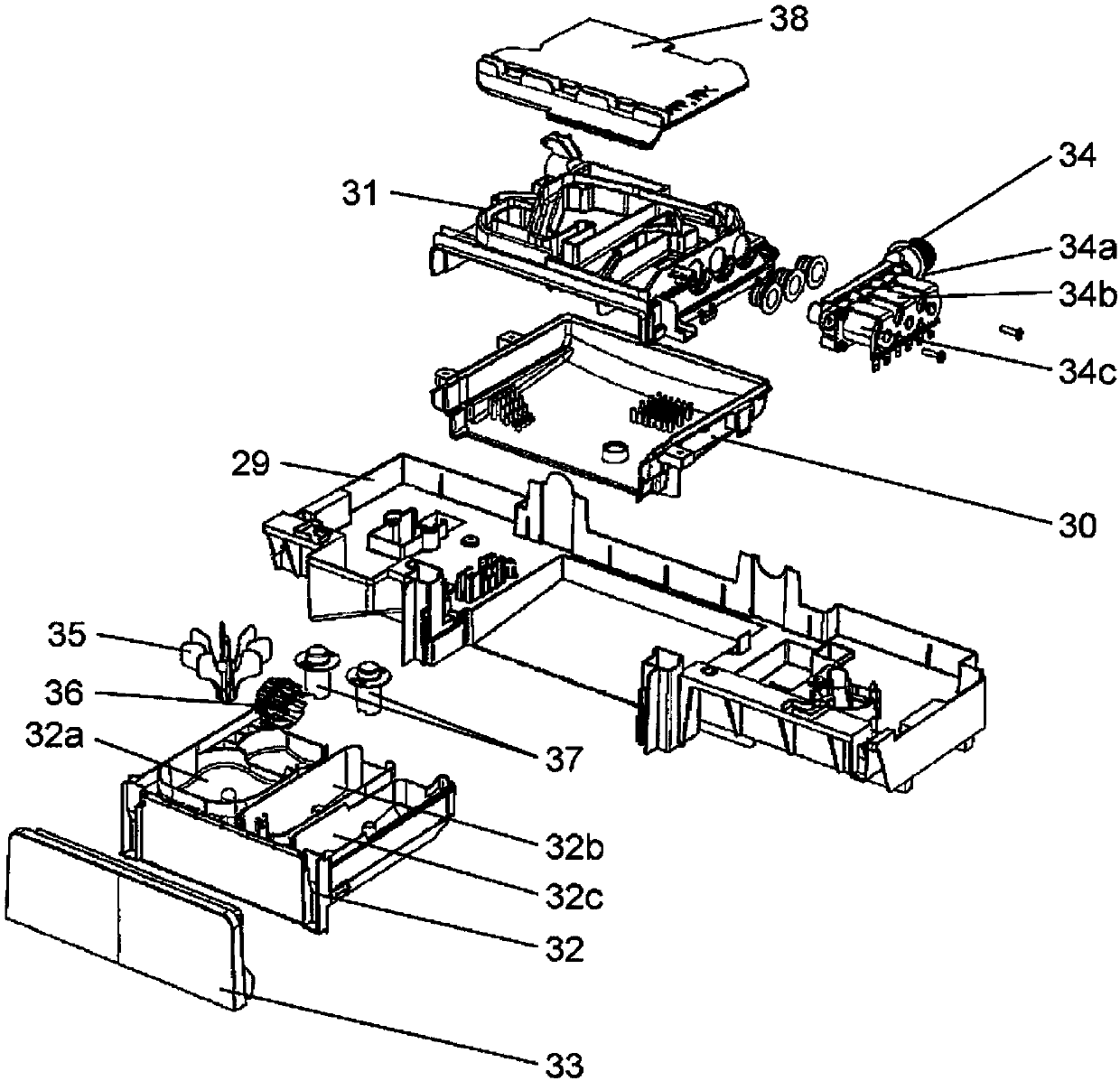

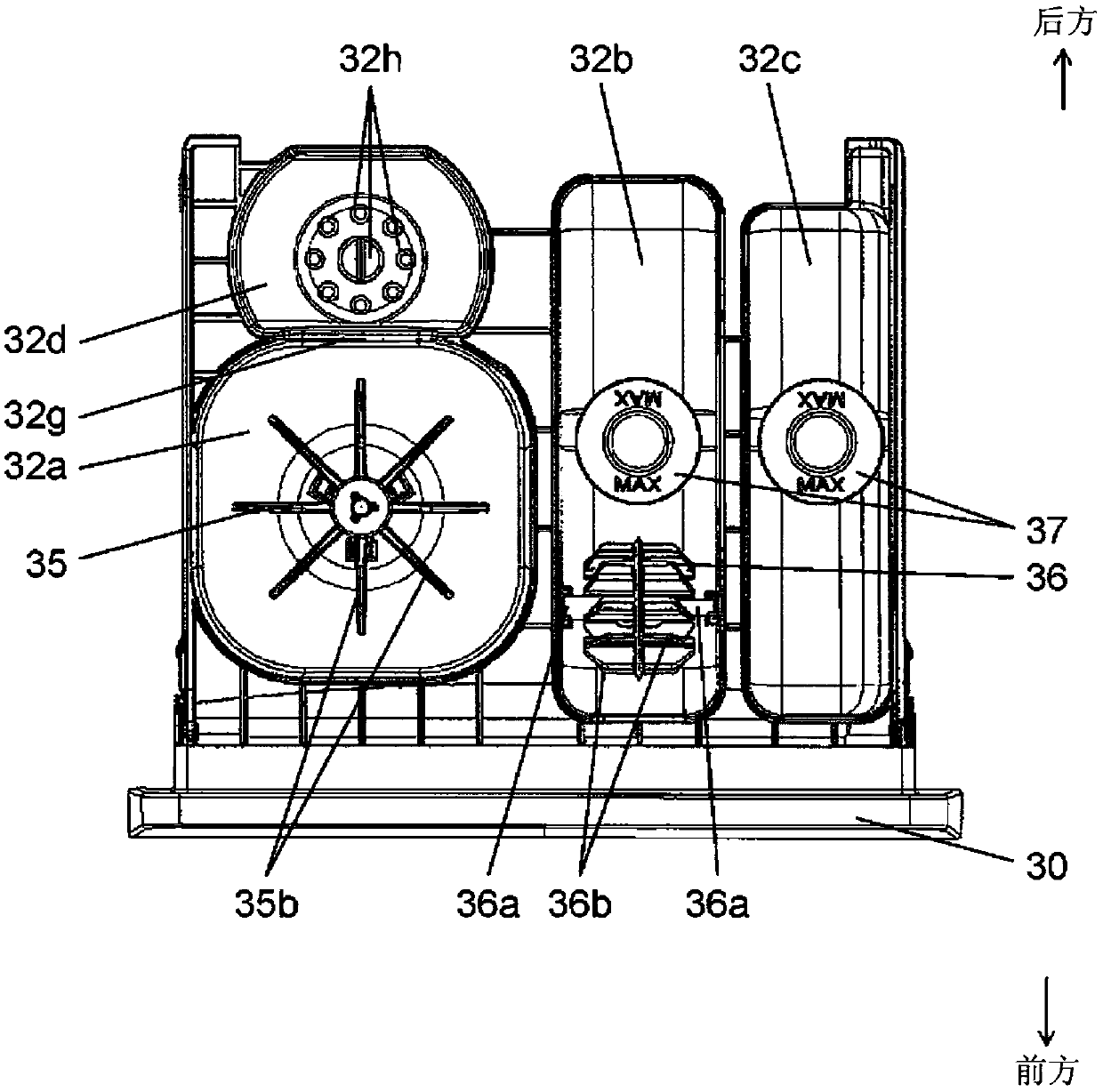

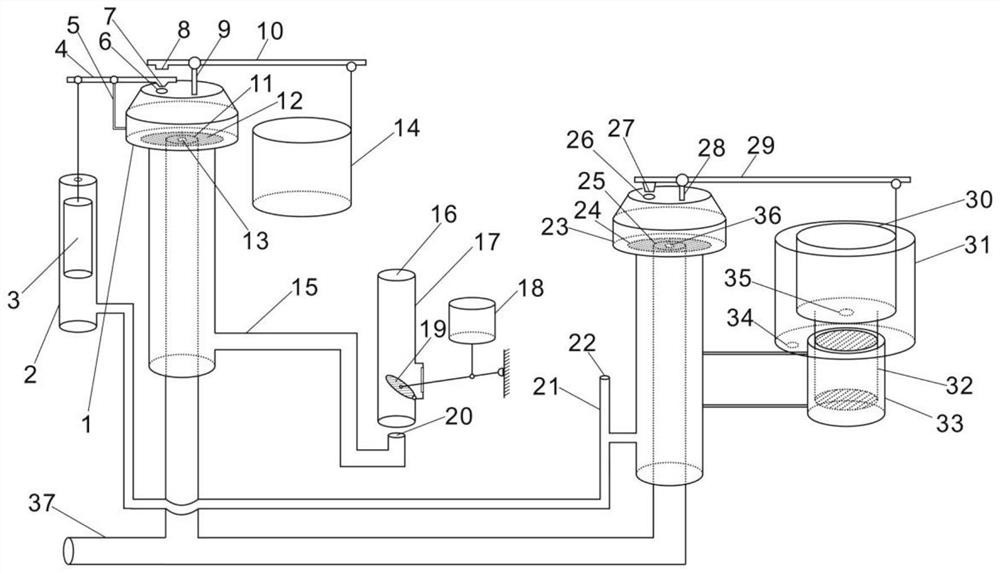

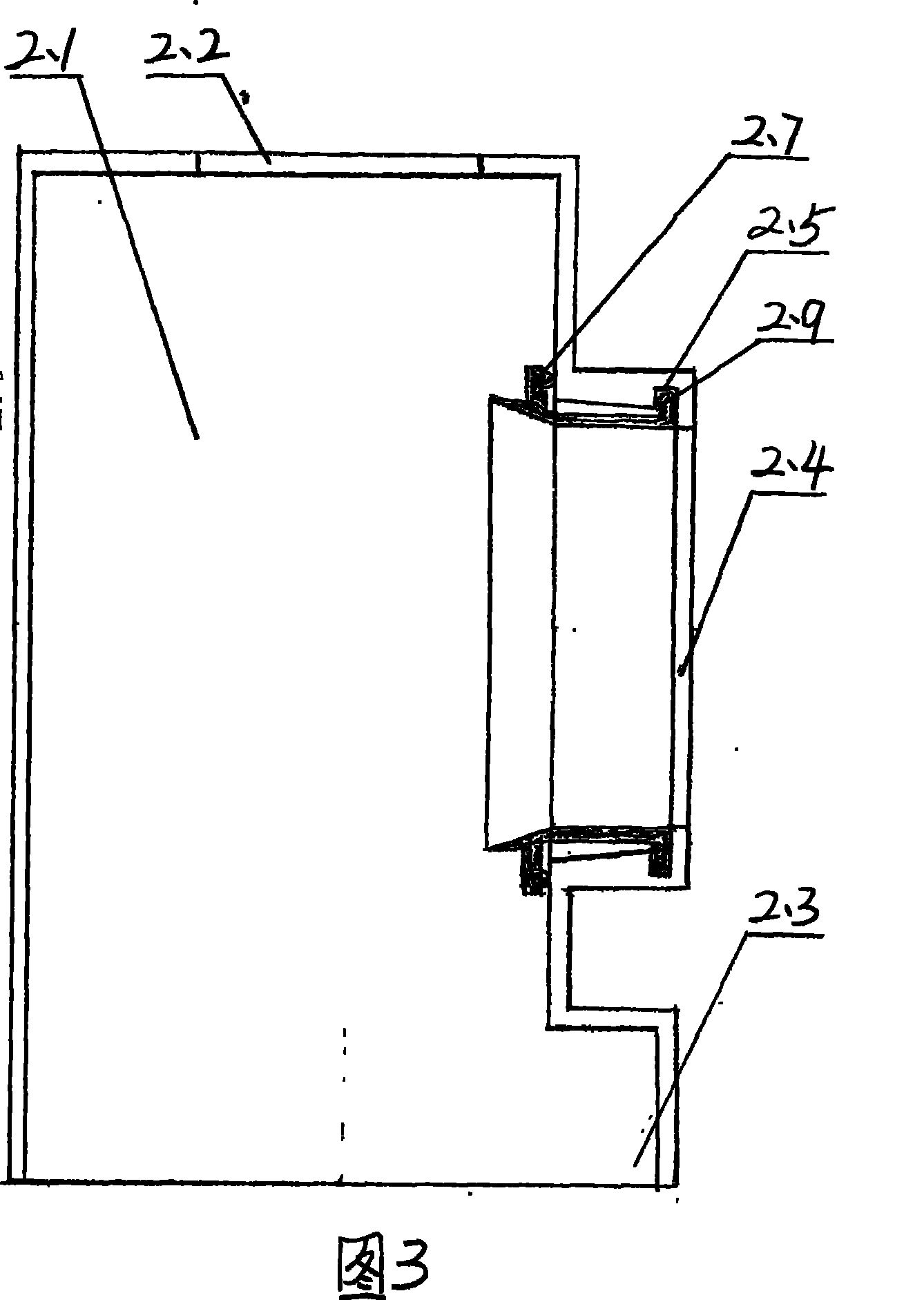

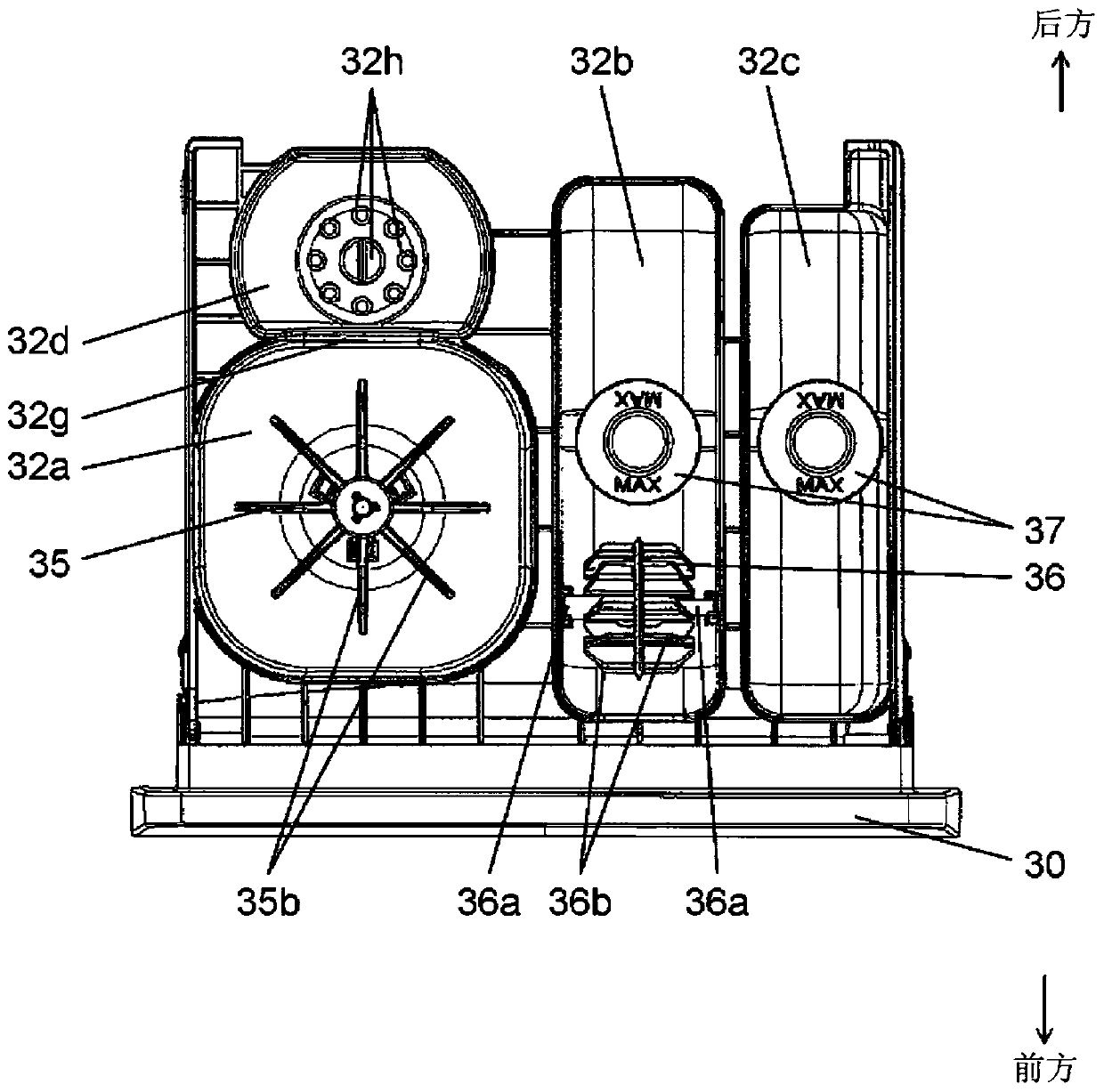

Washing machine

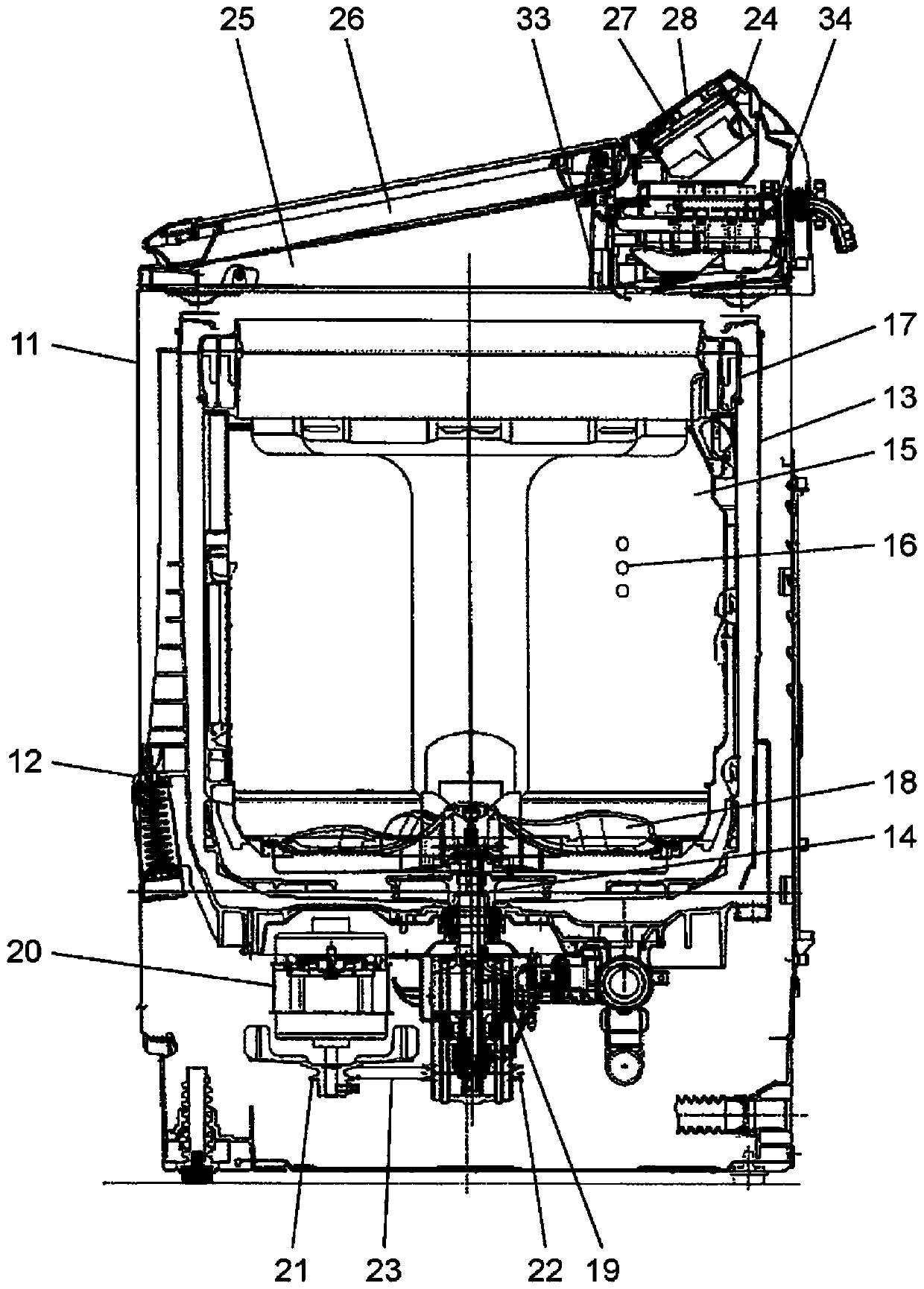

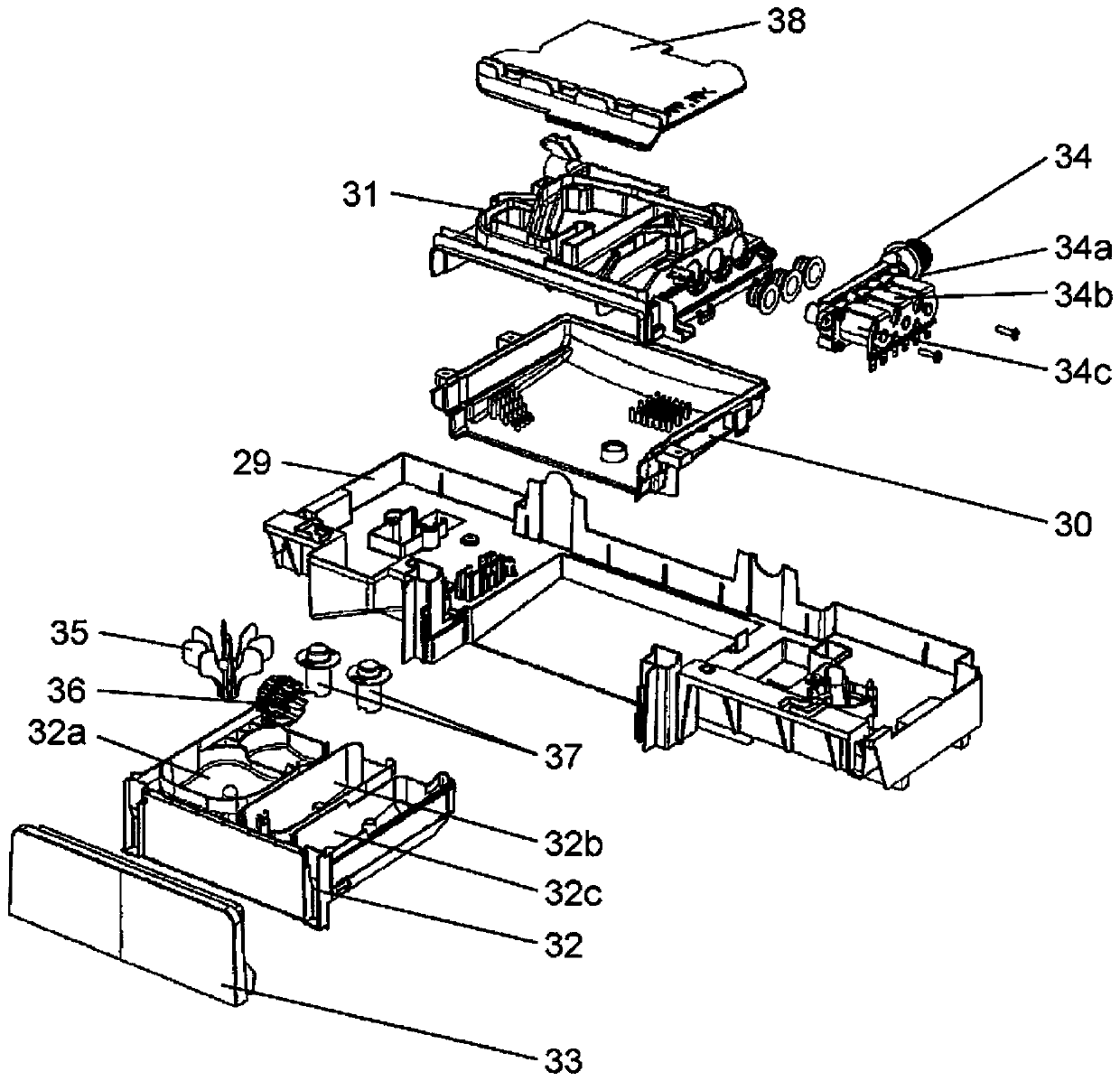

ActiveCN109563674AHigh dilution rateOther washing machinesControl devices for washing apparatusLaundry washing machineWater flow

The present invention is provided with: an accommodation case having a powder detergent accommodation part (32a), a liquid detergent accommodation part, and a softener accommodation part; and a water-pouring case (31) that pours water into the accommodation case. The present invention is also provided with a first water flow passage (31a), provided in the water-pouring case (31), for pouring waterinto the powder detergent accommodation part (32a), and a first water feed valve (34a) communicating with the first water flow passage (31a). The present invention is also provided with a second water flow passage, provided in the water-pouring case (31), for pouring water into the powder detergent accommodation part (32a) and the liquid detergent accommodation part, and a second water supply valve communicating with the second water flow passage. The present invention is also provided with a third water flow passage, provided in the water-pouring case (31), for pouring water into the softener accommodation part, and a third water supply valve communicating with the third water flow passage. The present invention is further provided with nozzles (31d, 31e, 31f), disposed in the first water flow passage (31a), second water flow passage, and third water flow passage, for supplying water to the powder detergent accommodation part (32a), the liquid detergent accommodation part, and the softener accommodation part.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Laser cladding tungsten carbide ceramic particle reinforced metal-based coating and its processing method

ActiveCN105112908BImprove bindingImprove wettabilityMetallic material coating processesAlloyChromium

The invention discloses a metal-based coating reinforced by laser cladding tungsten carbide ceramic particles, which includes alloy powder, the alloy powder includes tungsten powder and graphite with a molar ratio of 2:1, and the alloy powder also includes reduced iron powder and chromium powder , nickel powder, boron powder, silicon powder and copper powder; the composition and percentage mass ratio of further preferred alloy powder are respectively: tungsten powder 55-60%, graphite 7-9%, reduced iron powder 23-30%, chromium 0-3% nickel powder, 2-6% nickel powder, 0.3-1% boron powder, and 0.4-1% silicon powder; the invention also discloses a processing method for laser cladding tungsten carbide ceramic particle reinforced metal-based coating, the invention The tungsten carbide particle reinforcement phase was successfully prepared by laser cladding in-situ synthesis technology to strengthen the iron-based composite material. There is a transition layer between the coating and the substrate, indicating that they are atomically bonded and have a high bonding strength.

Owner:WENZHOU UNIVERSITY

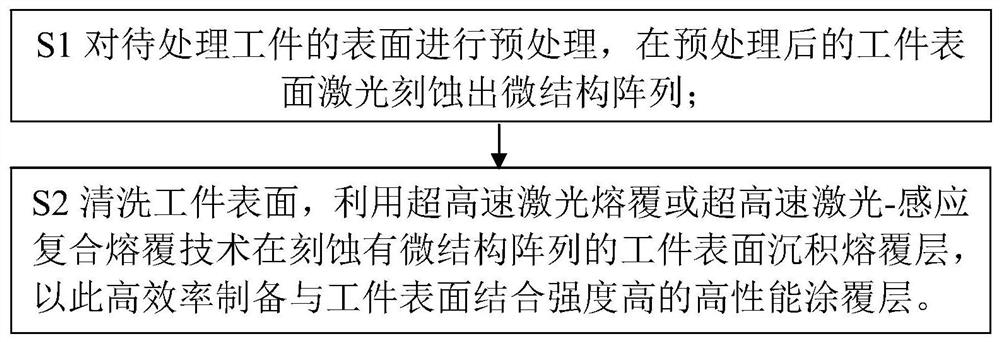

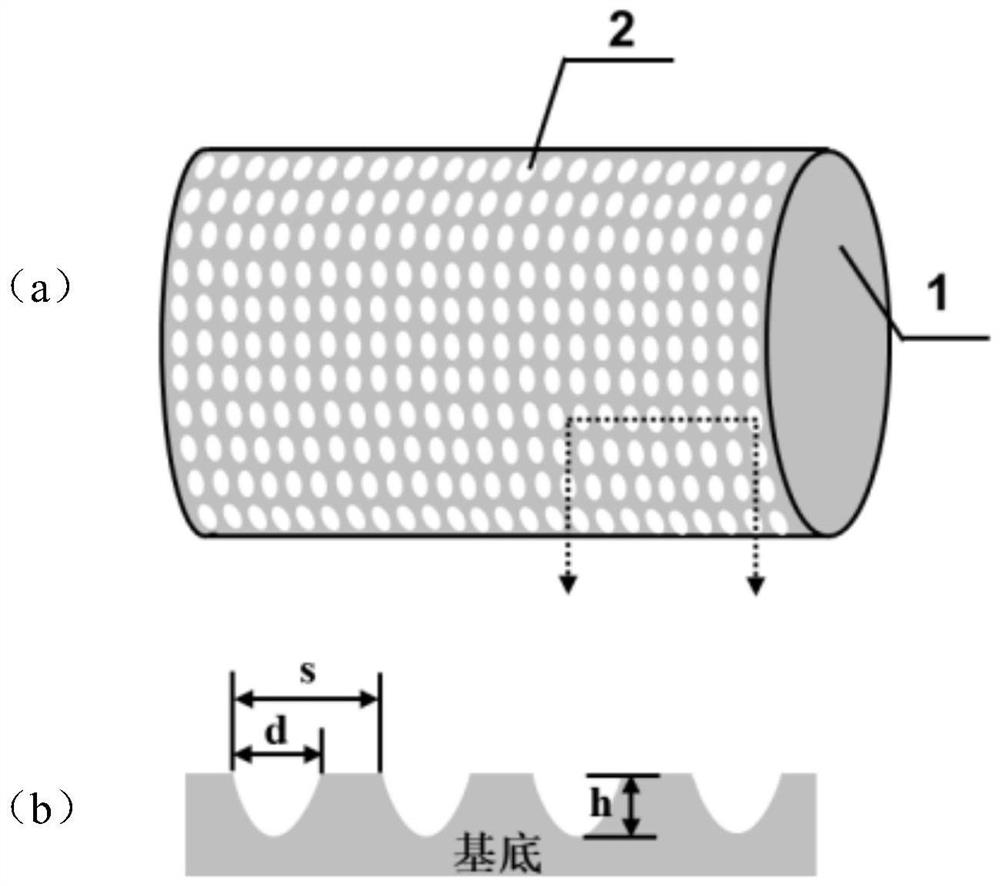

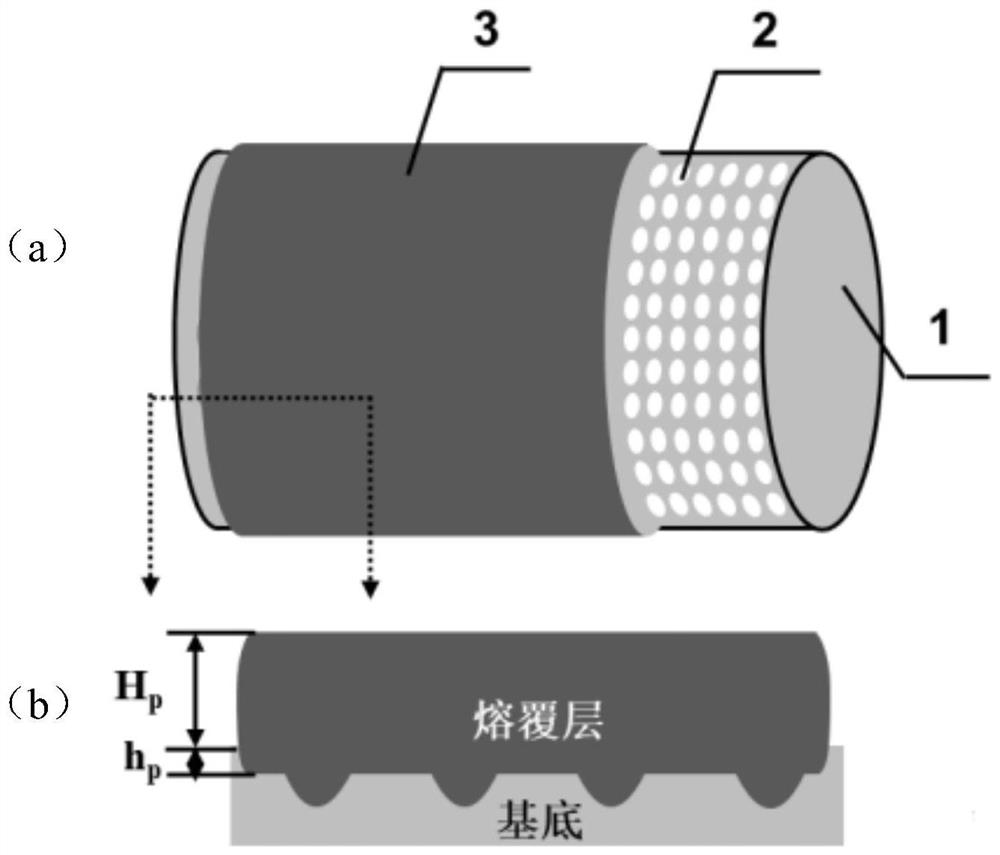

Method and device for efficiently preparing high-performance coating layer

PendingCN112323061AEfficient preparationImprove production efficiencyMetallic material coating processesLaser etchingUltra high speed

The invention belongs to the field of surface coating processing, and particularly discloses a method and a device for efficiently preparing a high-performance coating layer. According to the method,firstly, laser etching is carried out on the surface of a workpiece to be treated to form a microstructure array; and then a cladding layer is deposited on the surface of the workpiece etched with themicrostructure array by utilizing an ultra-high-speed laser cladding technology or an ultra-high-speed laser induction composite cladding technology so as to realize high-efficiency preparation of the high-performance coating layer. According to the method and the device, while the high-performance cladding layer is prepared on the surface of a metal component, the interface bonding area and bonding strength of the cladding layer and a substrate can be improved, the interface stress of the cladding layer and the substrate is reduced, the cladding layer is prevented from being broken and peeled off in the service process, and then the fatigue performance and friction and wear properties of the cladding layer are improved.

Owner:武汉飞能达激光技术有限公司

Pretreatment method for breeder duck egg hatching

InactiveCN107258688AImprove hatchabilityImprove permeabilityAnimal husbandryPretreatment methodDisinfectant

The invention discloses a pretreatment method for breeder duck egg hatching. The method includes the steps that 1, breeder duck eggs laid by breeder ducks are washed clean with warm water and then disinfected with disinfectant; 2, the breeder duck eggs are placed in mixed straw, and the environment temperature is controlled to be 22-26 DEG C; 3, a hatching solution is sprayed to the duck eggs every day, and 5-7 days later, the duck eggs are taken out to be hatched. The pretreatment method for breeder duck egg hatching is easy to implement, safe and environmentally friendly, and can effectively increase the hatching rate of the breeder duck eggs and improve the quality of ducklings obtained after hatching.

Owner:合肥市明航养殖有限公司

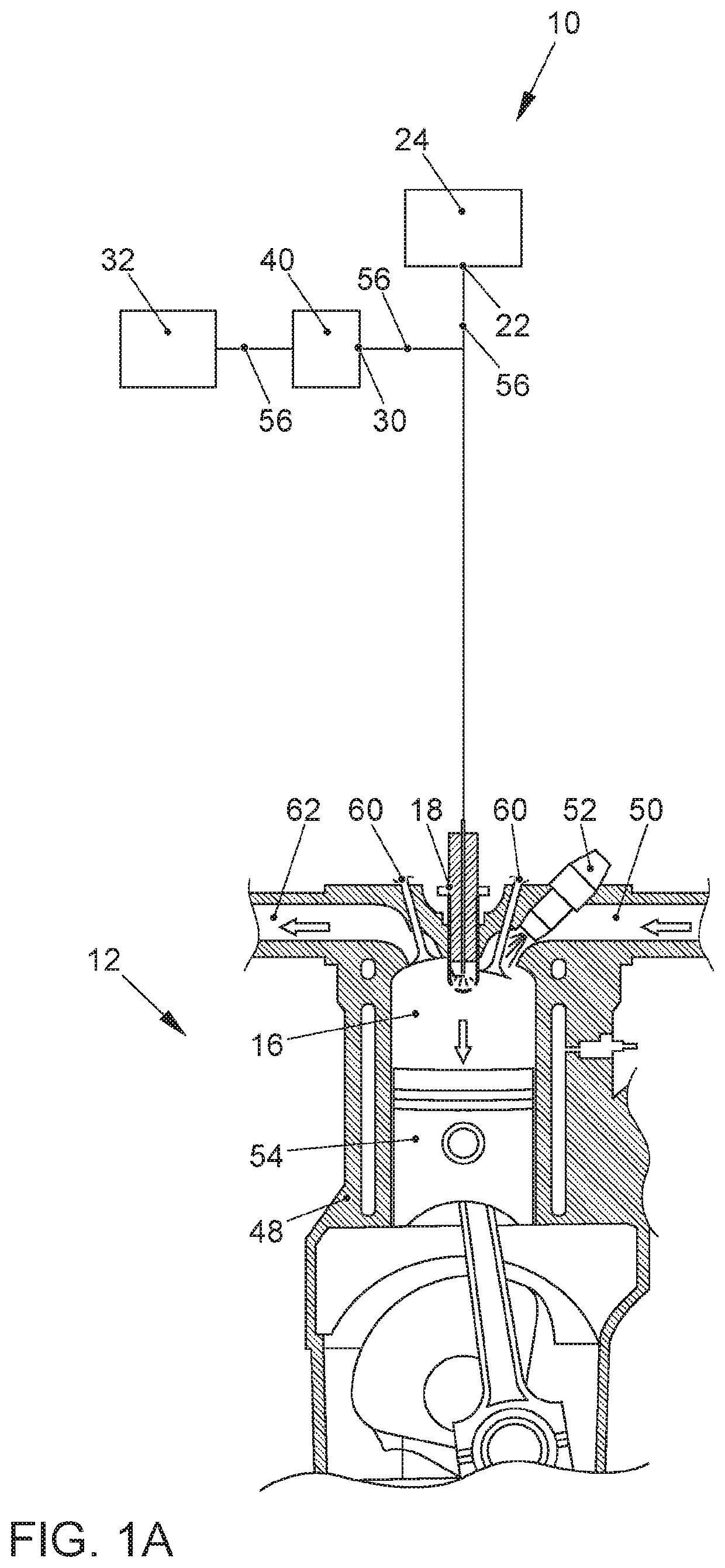

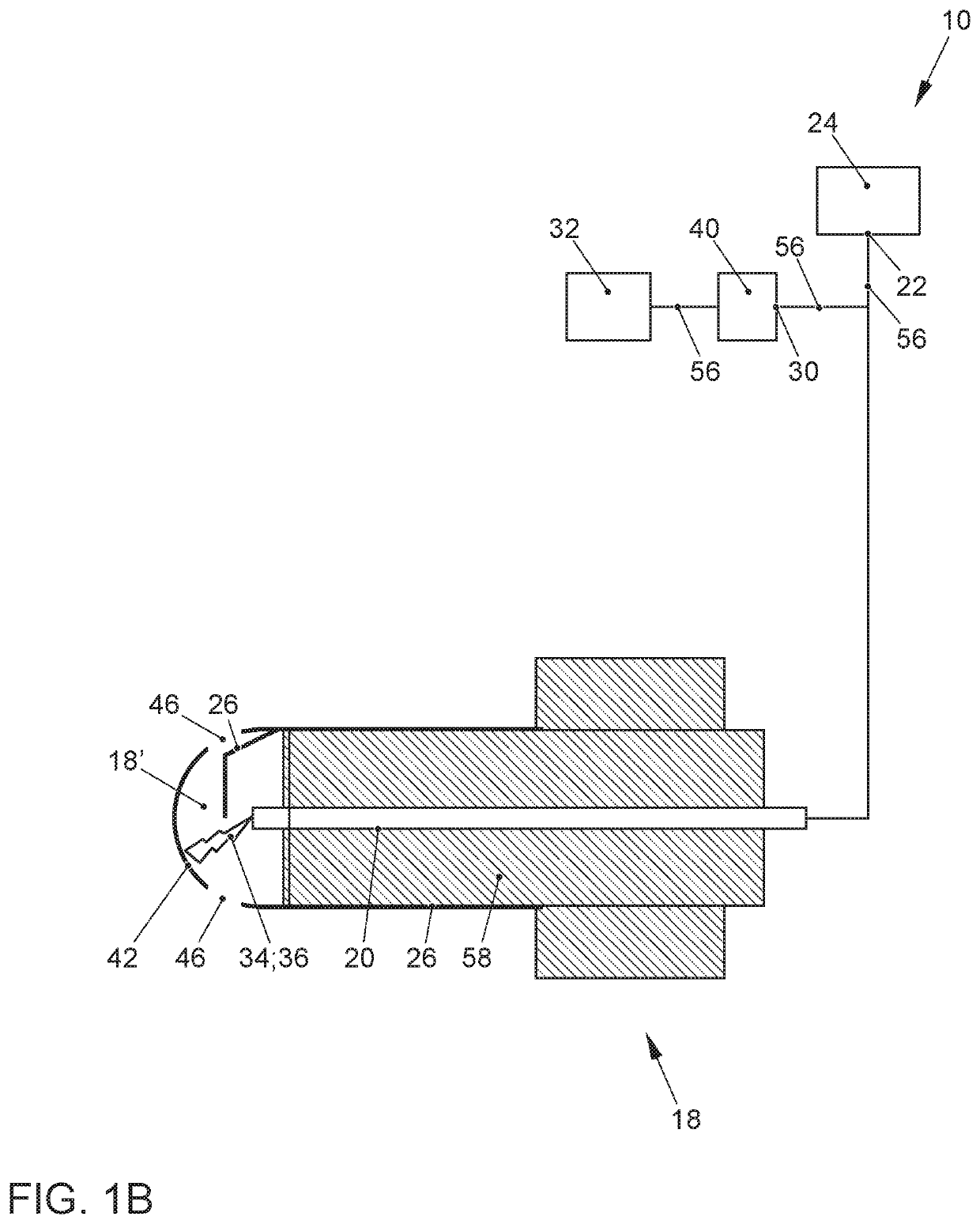

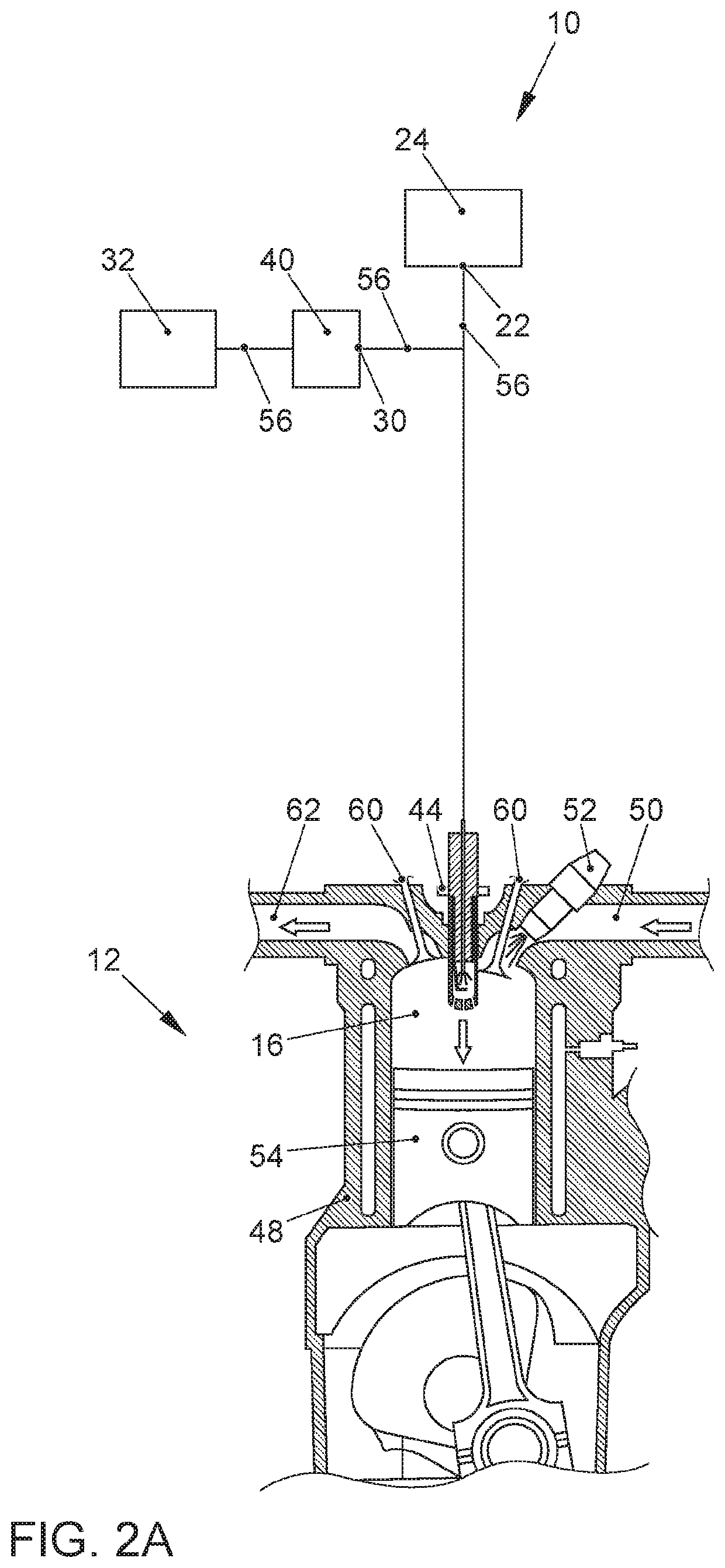

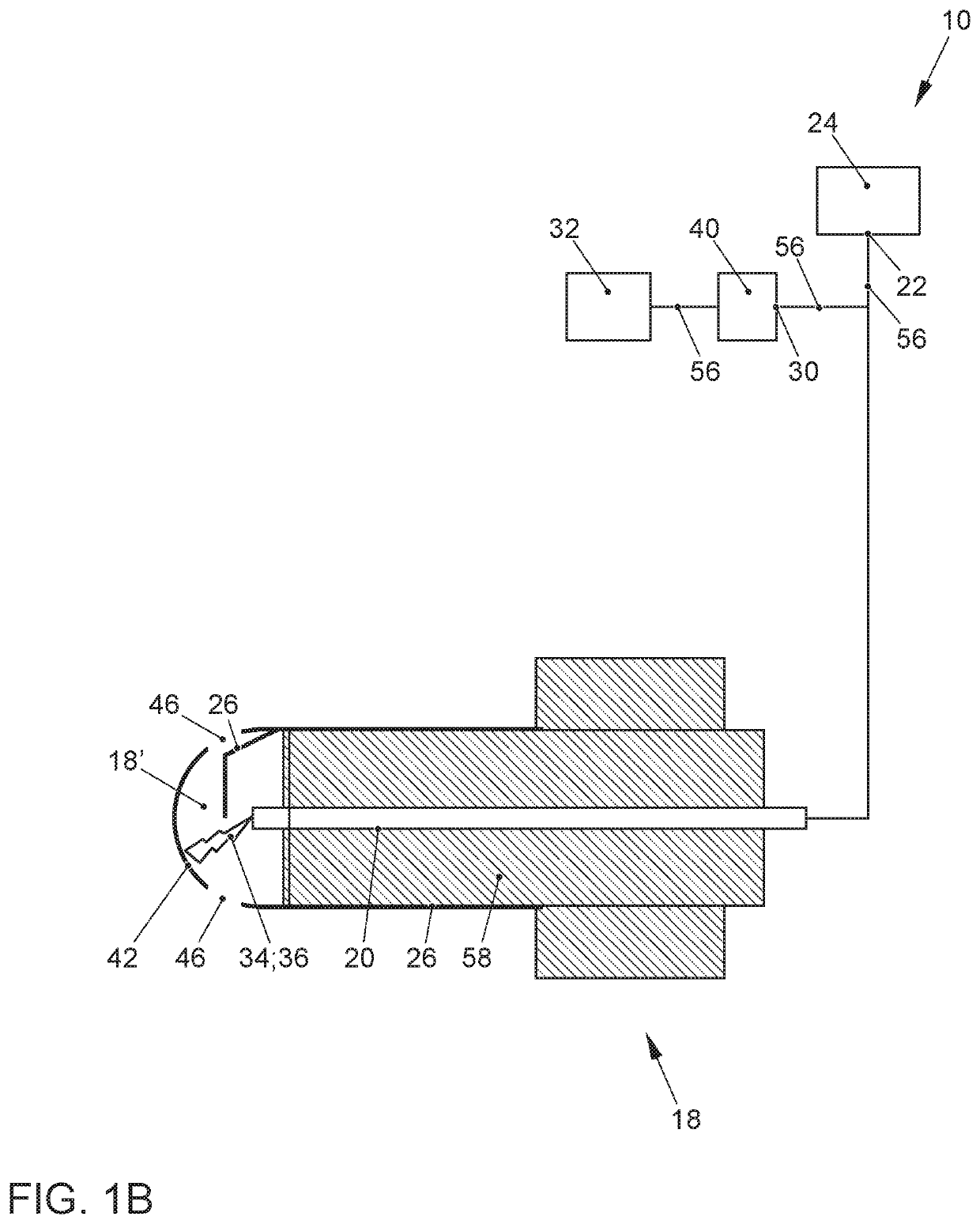

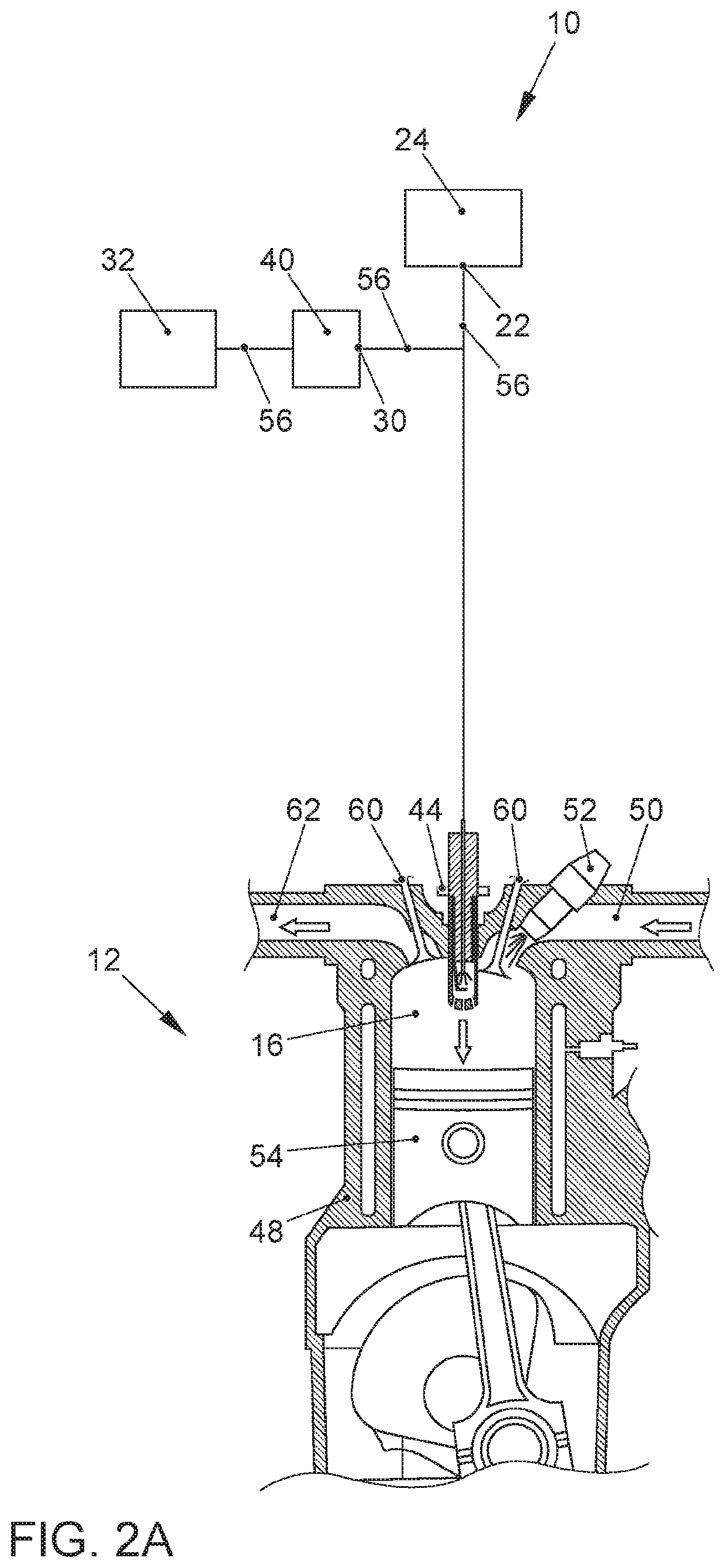

Ignition system having a high-frequency plasma-enhanced ignition spark of a spark plug, including an antechamber, and a method associated therewith

ActiveUS10830201B2Improve ignition reliabilityEnsure complete combustionSparking plugsCombustion enginesCombustion chamberInternal combustion engine

Owner:VOLKSWAGEN AG +1

Nickel base alloy and rustless steel valve possessing nickel base alloy layer seal surface and its preparation method

ActiveCN100575519CHigh dilution rateHigh hardnessMetallic material coating processesCarbideMetal silicide

Owner:有研金属复材技术有限公司

High-temperature gradient wear-resistant coating as well as preparation and application thereof

ActiveCN114574852AGood high temperature wear resistanceExcellent high temperature wear resistanceTransportation and packagingMetal-working apparatusVulcanizationCarbide

The invention belongs to the field of wear-resistant materials, and particularly discloses a high-temperature gradient wear-resistant coating which comprises a bottom layer, a transition layer, a wear-resistant layer and a vulcanization layer formed by vulcanization on the surface of the wear-resistant layer. The bottom layer comprises a martensite matrix and an intermetallic compound dispersed in the martensite matrix; each of the transition layer and the wear-resistant layer comprises a martensite matrix as well as an intermetallic compound and a carbide which are dispersed and distributed in the martensite matrix; wherein the content of intermetallic compounds in the transition layer and the wear-resistant layer is greater than the content of intermetallic compounds in the bottom layer; and the content of carbide in the wear-resistant layer is greater than that in the transition layer. The invention further comprises preparation and application of the coating, a wear-resistant material with the coating and preparation of the wear-resistant material. The research finds that the intermetallic compound and carbide double-gradient controlled hierarchical coating has excellent synergism, and the high-temperature (such as 700 DEG C) wear resistance of the coating can be remarkably improved.

Owner:长沙市萨普新材料有限公司

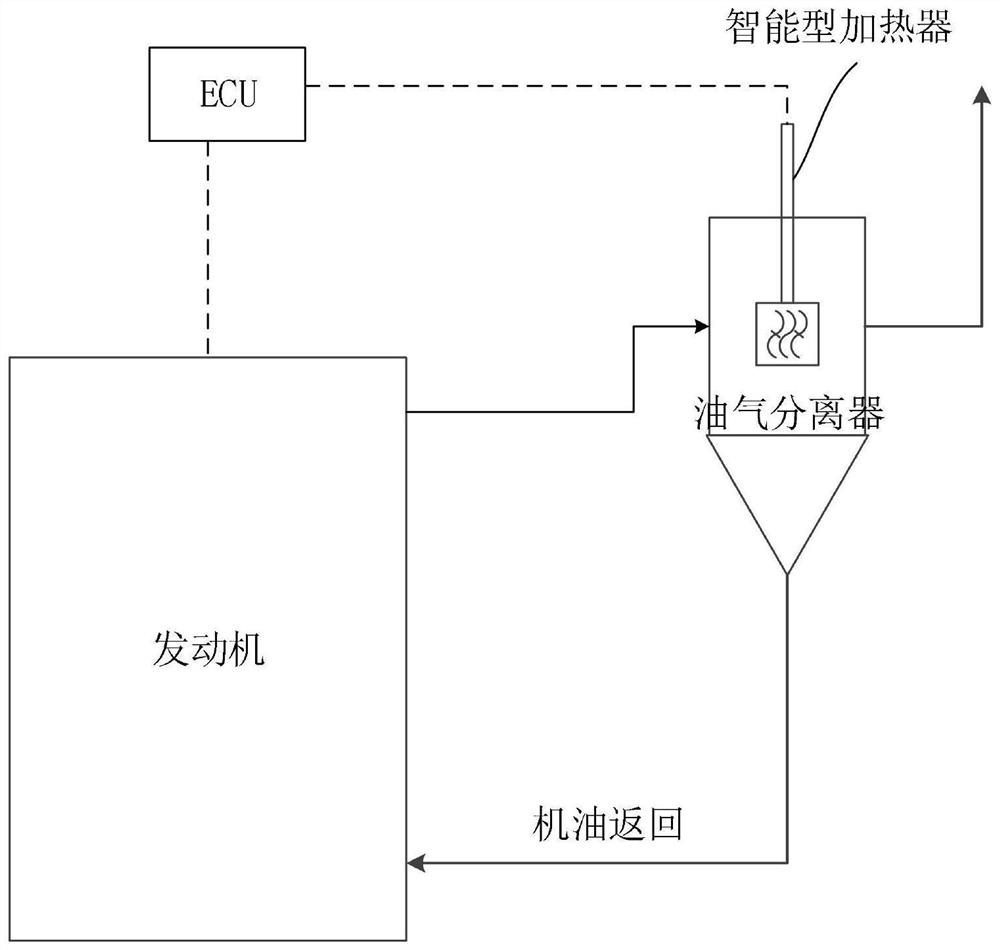

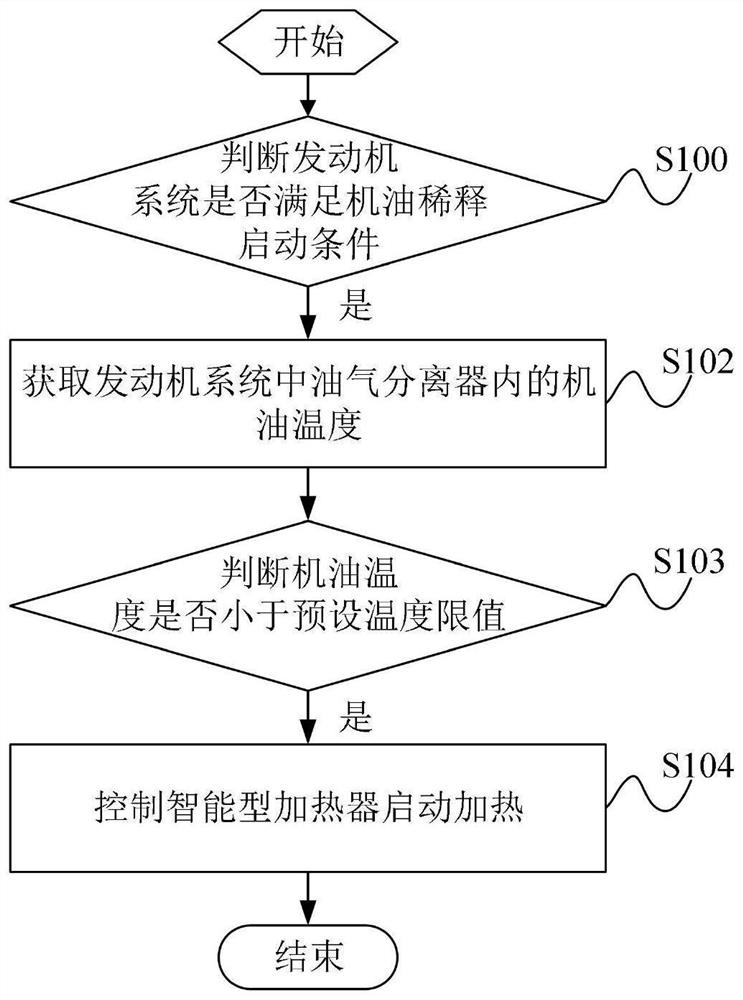

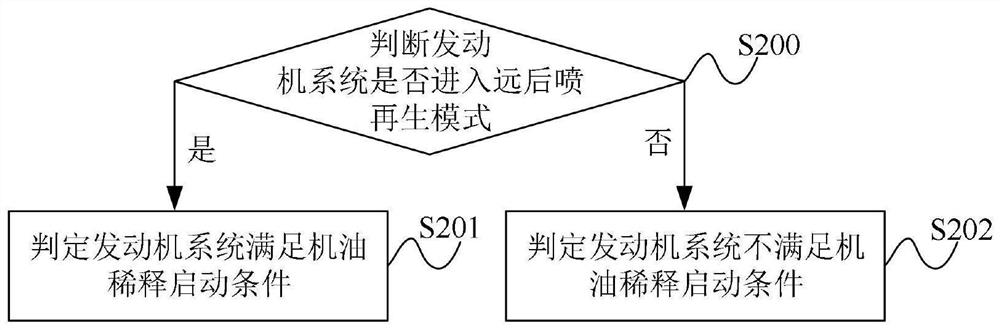

Control system and method for reducing engine oil dilution rate of engine system

PendingCN114352377ALow dilution rateHigh dilution rateMachines/enginesLubrication indication devicesControl systemDieseling

The invention provides a control system and method for reducing the engine oil dilution rate of an engine system. The system comprises an electronic control unit and an intelligent heater arranged in an oil-gas separator in the engine system. The intelligent heater is in communication connection with the electronic control unit; the intelligent heater is used for detecting the temperature of engine oil in the oil-gas separator and heating the engine oil in the oil-gas separator according to a control instruction issued by the electronic control unit; the electronic control unit is used for issuing a control instruction to the intelligent heater according to the operation condition of an engine system and engine oil temperature data, diesel oil mixed into engine oil in the oil-gas separator can be volatilized, the engine oil dilution rate is reduced, and the situation that the engine oil dilution rate is too high is avoided. The oil change period is short; the risk of long-term use is high; and the performance of the diesel engine is reduced.

Owner:WEICHAI POWER CO LTD

Intermittent control water inlet valve

ActiveCN111139903BRealize function conversionImprove performanceFlushing devicesTap waterInlet valve

The invention discloses an intermittent control water inlet valve, which comprises a water inlet pressure difference valve, an intermittent lever, a water inlet pressure relief hole, a water inlet block, a water outlet pipe of the water inlet valve, a textured water outlet, a switching valve plate, an inlet Water valve full-pressure spout, auxiliary flushing outlet, auxiliary flushing differential valve, time-controlled water bucket, time-delayed water bucket, constant force float, tap water inlet pipe, etc. When the water level in the toilet tank drops to a certain depth, the auxiliary flushing valve The constant force bucket controlled by the time-delay adjustment hole falls to make the piston go up, and the tap water inlet pipe has only one outlet for flushing, and the full pressure realizes the replacement of toilet dirt; when the timing is controlled, the outlet for flushing is controlled by the auxiliary flushing outlet to complete the replacement After the task, add water to the water tank of the toilet through the textured water outlet; when the water tank of the toilet is filled with water, plug the force point to press down the intermittent lever, block the water inlet and pressure relief hole, and realize the tap water well. The full pressure of the water inlet pipe controls the washing and replacement of the toilet respectively, which improves the use function of the toilet as much as possible.

Owner:GUANGDONG HEGII SANITARY WARES CO LTD

A kind of preparation method of low turbidity bisphenol A type cyanate ester prepolymer

The invention discloses a preparation method of a low-turbidity bisphenol A type cyanate ester prepolymer. The preparation method of the low-turbidity bisphenol A type cyanate ester prepolymer comprises the steps that diphenol propane, cyan chloride and triethylamine are dissolved in a solvent for participating in a reaction, and recrystallization is carried out to obtain the low-turbidity bisphenol A type cyanate ester prepolymer; reaction liquid by vaporific injection is in fully contact with a catalyst in an internal atomization chamber through an atomization reaction device, the conversionrate of the bisphenol A type cyanate ester prepolymer is increased by 85-95%, and product turbidity and purification difficulty are effectively reduced; and a phase transfer catalyst is mixed with ethyl alcohol to form a catalyst for participating in a reaction, local polymerism taking the catalyst as the center cannot occur at an initiating stage, gels and solid particles cannot be formed, so that reactants are sufficiently in contact with each other, the reaction is more thorough, the turbidity of a reaction system is greatly reduced, the purification difficulty is further reduced, and theturbidity of the obtained bisphenol A type cyanate ester prepolymer is less than or equal to 5 FTU after detection, and is greatly superior to the standard of being less than or equal to 10 FTU in theprior art.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

Ignition system having a high-frequency plasma-enhanced ignition spark of a spark plug, including an antechamber, and a method associated therewith

ActiveUS20200116119A1Easy to igniteImprove ignition reliabilitySparking plugsCombustion enginesCombustion chamberInternal combustion engine

An ignition system and a method for a spark-ignition combustion engine having a high-frequency plasma-augmented ignition spark, the spark ignition of the fuel being realized by at least one spark plug associated with a combustion chamber of the combustion engine. The spark plug has a prechamber having at least one opening via which the prechamber communicates with the combustion chamber on the fuel side, so that the ignition spark in the prechamber, into which the high-frequency plasma can be injected, induces the plasma-augmented spark ignition of the fuel in the prechamber.

Owner:VOLKSWAGEN AG +1

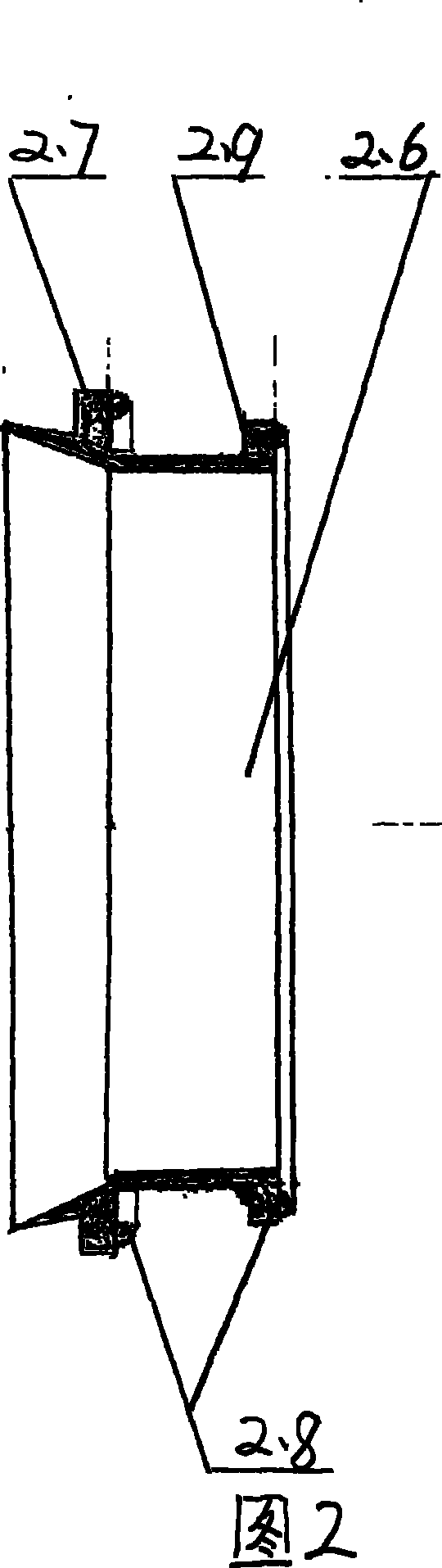

Consumable electrode surfacing method of electromagnetic complex field, and the device and extended application thereof

InactiveCN100551603CSteady Droplet Rotating JetWell formed weldWelding/cutting auxillary devicesArc welding apparatusComposite fieldAlloy

The present invention relates to one kind of composite electromagnetic field build-up welding method, apparatus and expanded application, and is composite electromagnetic field controlled gas protected build-up welding method. The welding apparatus is provided with exciting power source, exciting device, auxiliary electric field device and water cooling system. The exciting device has electromagnetic stirring exciting coil and electromagnetic heat treatment exciting coil; and the auxiliary electric field device includes one pair of movable electrodes. Through electromagnetic stirring, electromagnetic heat treatment and the compound effect of auxiliary electric field and the welding torch, the present invention realizes the build-up welding of alloy material in high efficiency, high quality and low cost.

Owner:CHONGQING UNIV

Hollow tungsten electrode arc coaxial laser composite wire filling welding method

PendingCN112809185ASpeed up meltingImprove deposition efficiencyArc welding apparatusLaser beam welding apparatusElectric arcPlasma flow

The invention provides a hollow tungsten electrode arc coaxial laser composite wire filling welding method. The problems that in the hollow tungsten electrode arc wire filling welding process, the current density, temperature and plasma flow speed on the hollow tungsten electrode arc center axis are obviously reduced, consequently, the welding wire melting capacity is poor, and the deposition efficiency in the welding process is not high are solved. The method comprises the following steps: grinding or cleaning a to-be-welded workpiece, and fixing the ground or cleaned to-be-welded workpiece; and adjusting the relative position of laser and the hollow tungsten electrode axis, and enabling the laser to penetrate through the center of a hollow tungsten electrode. Paraxial wire feeding is adopted, the welding wire feeding angle and position are adjusted, and the laser directly irradiates the surface of a welding wire after penetrating through the hollow tungsten electrode; hollow tungsten electrode arc parameters and laser parameters are set; and a control switch is turned on, a hollow tungsten electrode arc is generated, and the laser is emitted from the center of the hollow tungsten electrode to an arc area and directly acts on the surface of the welding wire. The hollow tungsten electrode arc coaxial laser composite wire filling welding method is used.

Owner:HARBIN WELDING INST LTD

Poly-isocyanurate polyurethane coating curing agent and preparation method thereof

ActiveCN102115525BGood compatibilitySimple production processPolyurea/polyurethane coatingsChemical structureWeather resistance

The invention relates to a poly-isocyanurate polyurethane coating curing agent and a preparation method thereof. The curing agent is isozyanurat ring-containing structure and polyurethane prepolymer solution of which end is sealed by NCO group by the means that isozyanurat-based polyether glycol is reacted with polyisocyanate in acetate dissolvants, and polymerization inhibitor is further added into the solution. The curing agent has the chemical structure which is similar to isocyanate tripolymer curing agent; the curing agent is low in viscosity, good in storing stability, and low in cost; and the hydroxy acrylic resin and the alkyd resin are good in consistency. The prepared film has the characteristics of being good in adhesive force, flexibility, thermostability, weather resistance and corrosion resistance, high in hardness and the like, thereby being applicable to the high-grade field of vehicle painting.

Owner:SHANDONG INOV POLYURETHANE

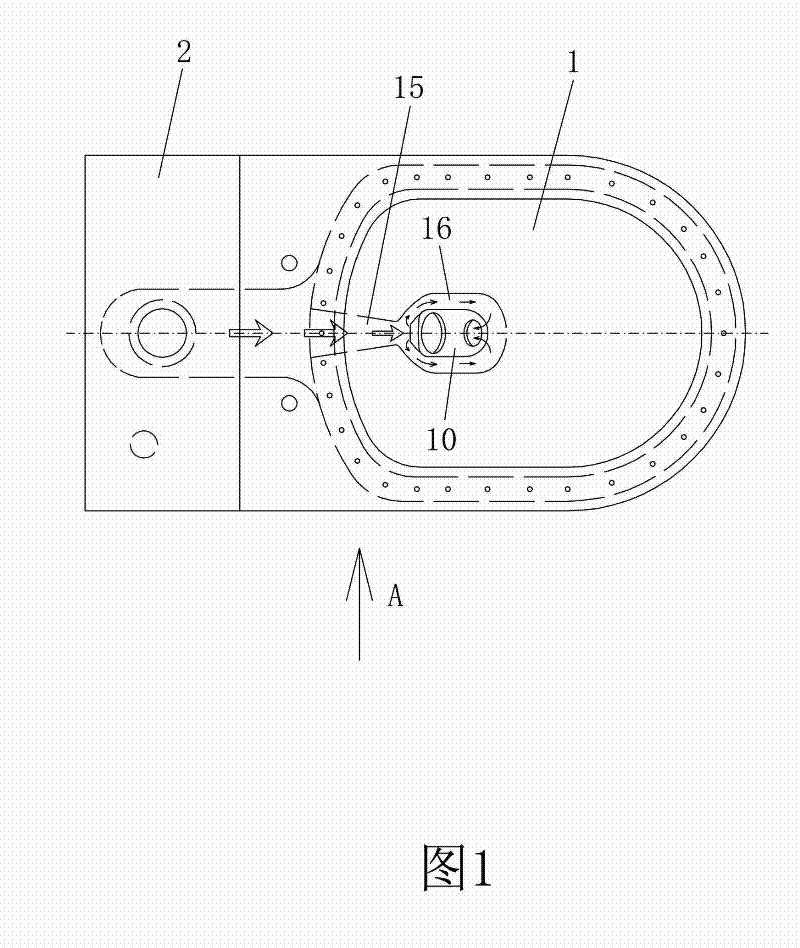

Moderate and high strength large-thickness component narrow gap or ultra-narrow gap magnetic control jet molten welding method

InactiveCN101143401BWell formed weldLow costTransformers/inductances coolingWelding/cutting media/materialsExcitation currentEngineering

The invention relates to a gas shielded welding method and device of a narrow gap or a super-narrow gap impulse jet current consumable electrode controlled by electromagnetic of the heavy section part with middle and high strength. The invention uses a magnetic coil (3) to provide excitation current processed by an excitation source, which can generate an extra magnetic field. Under the conditions of narrow gap or super-narrow gap, high feed rate, fused drop spray transfer and impulse welding current, the process of the gas shielded welding of the rotating jet current consumable electrode with high-melting frequency pulse that is controlled by the electromagnetic for the heavy section part with middle and high strength can be realized. The device of the invention comprises the excitation source, excitation equipment, auxiliary equipment and a water cooling system. The excitation equipment is the magnetic coil (3) with or without a conducting core (5). The excitation equipment is fixedon a welding burner (6), which is positioned above a work piece (9). The excitation current provided by the excitation source (10) produces stationary or time-varying electromagnetic mixing magnetic field that has the combination control over the processes of arc welding, wire burn-off, drop transfer, melting bath flow and welding line coagulation, which finally forms the welding line of good quality.

Owner:CHONGQING UNIV

washing machine

ActiveCN109563674BHigh dilution rateOther washing machinesControl devices for washing apparatusLaundry washing machineWater flow

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

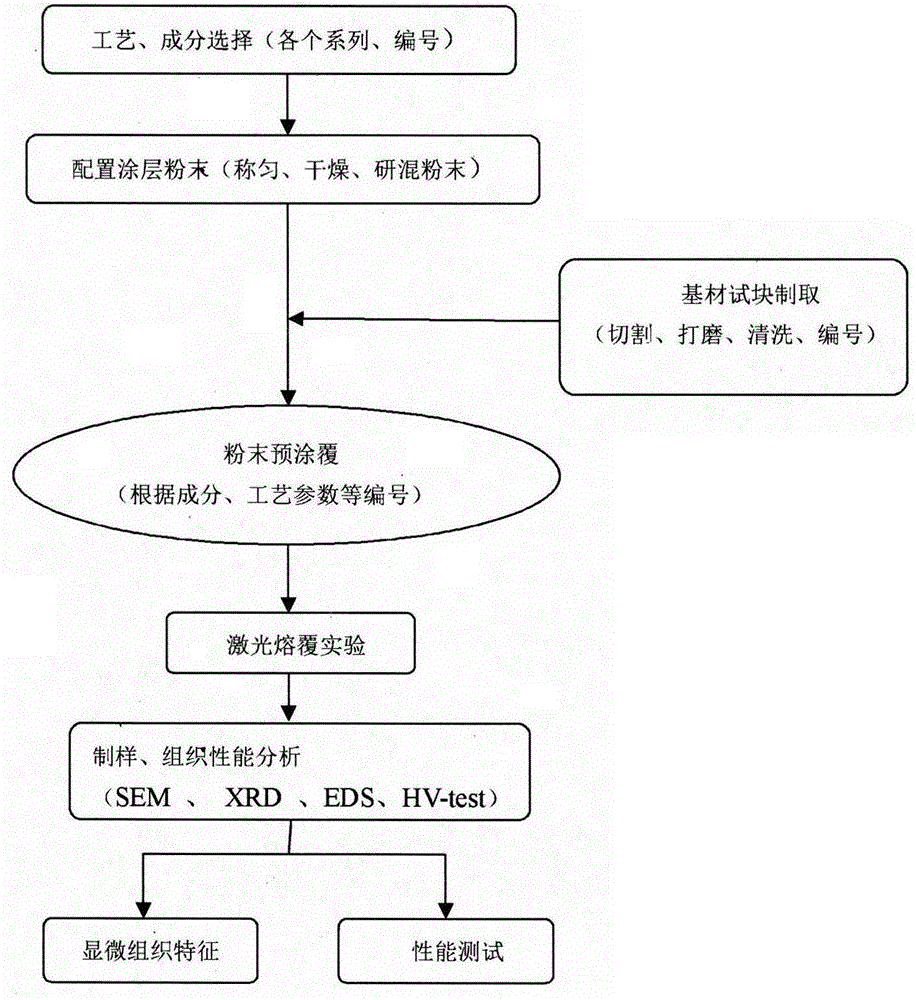

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com