High-temperature gradient wear-resistant coating as well as preparation and application thereof

A technology of wear-resistant coatings and wear-resistant layers, which is applied in the field of high-temperature gradient wear-resistant coatings for steel base parts and its preparation, can solve the problem of not being able to further improve the high-temperature wear resistance of materials, and easily generating thermal stress and interface stress , Insufficient wear resistance and other problems, achieve strong thermal stability and anti-aggregation ability, improve high temperature wear stability, reduce thermal stress and interface effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

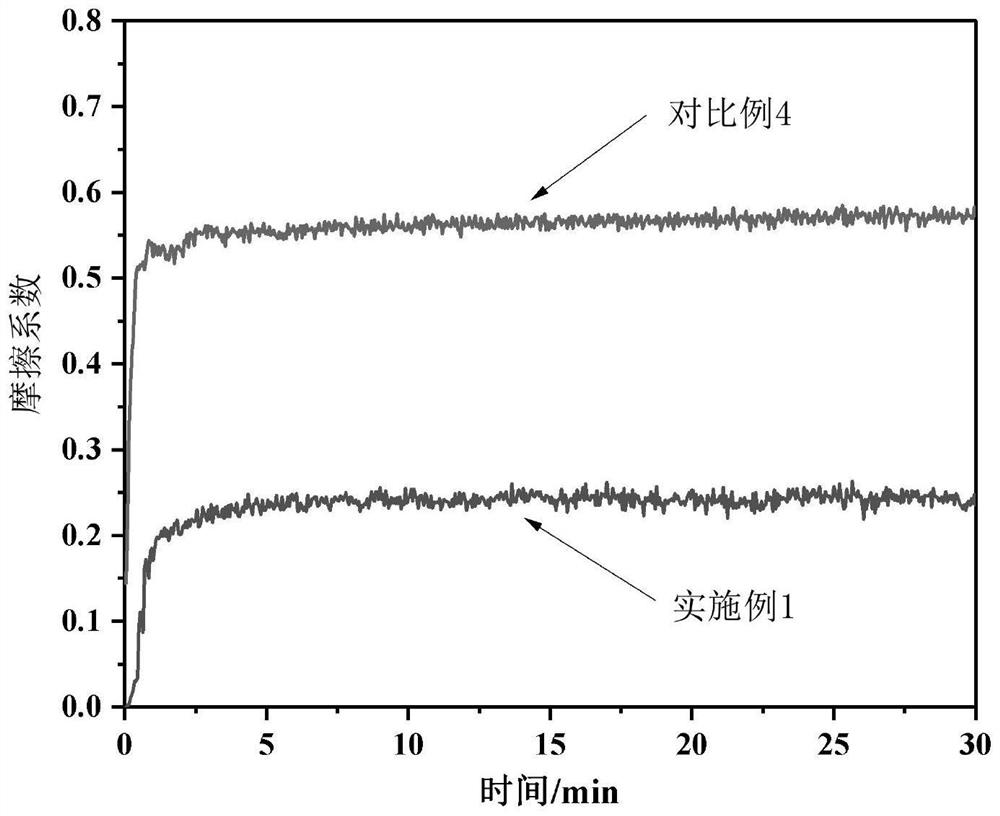

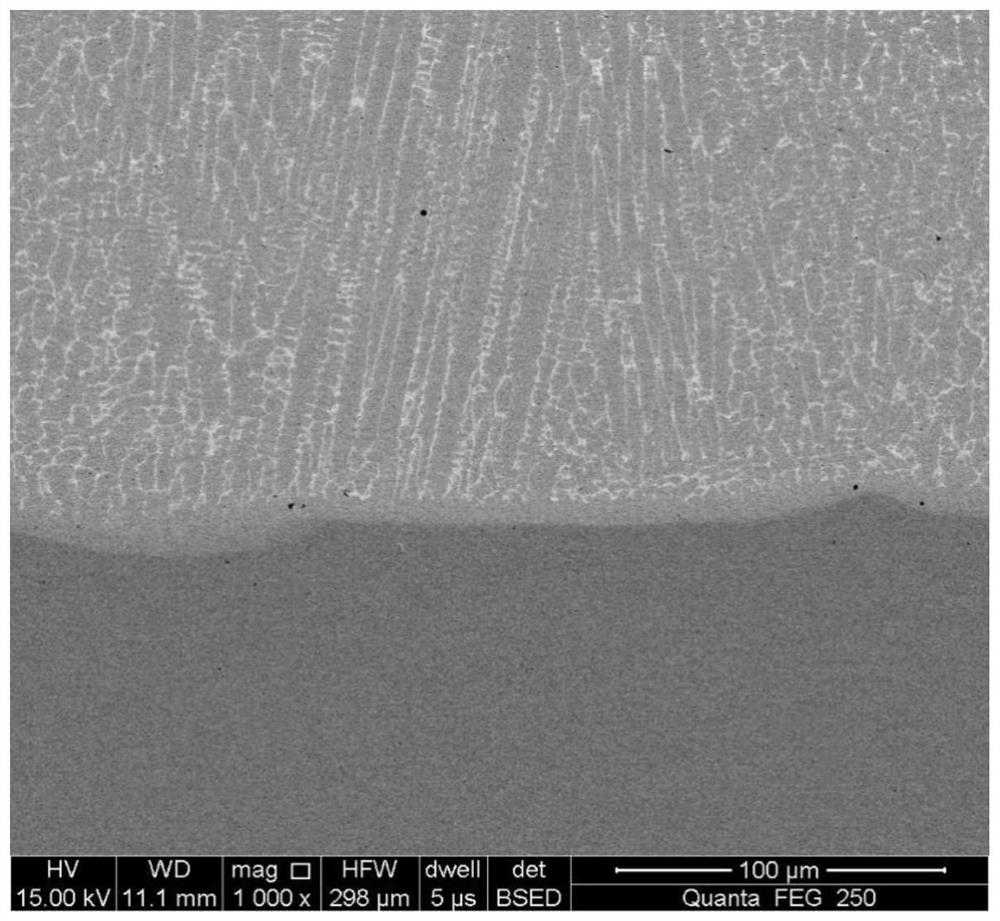

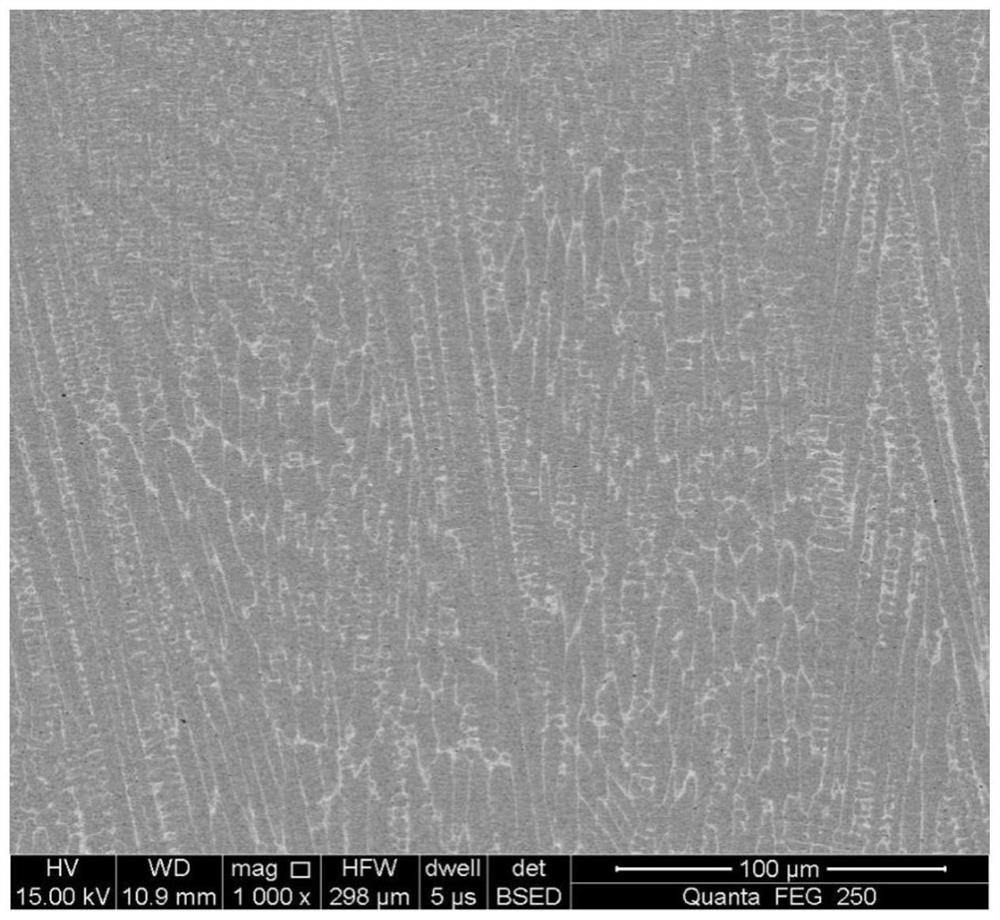

Embodiment 1

[0083] The raw materials are prepared according to the design plan: among them, the composition and proportion of the bottom layer are 12% Co, 6% Mo, 3% W, 0.5% Ni, 1% Ti, 1% Nb, 1% Cr, and the rest are Fe; the composition of the transition layer and The proportions are 20%Co, 12%Mo, 3%W, 2%WC, 1%TiC, 0.5%Ni, 1%Ti, 1%Nb, 0.5%Cr, and the rest are Fe; the composition and proportion of the wear-resistant layer are 22 %Co, 12%Mo, 4%W, 6%WC, 2%TiC, 0.5%Ni, 1%Ti, 1%Nb, 0.5%Cr, and the rest are Fe. The raw material powder, 0.5% B (based on the weight of the components of each layer), 0.5% Si (based on the weight of the components of each layer), and 3% paraffin (based on the weight of the components of each layer) were put into a roller ball mill for wetness. The ball milling medium is anhydrous ethanol, the ball-to-material ratio is 5:1, the ball milling time is 72h, and the ball milling speed is 150r / min. The ball-milled slurry is sprayed and granulated to obtain 80-150 μm powder,...

Embodiment 2

[0086] The raw materials are prepared according to the design plan: among them, the composition and proportion of the bottom layer are 10% Co, 4% Mo, 1% W, 0.5% Ni, 1% Ti, 1% Nb, 0.5% Cr, and the rest are Fe; the transition layer composition and The proportions are 15%Co, 9%Mo, 1%W, 1%WC, 1%TiC, 0.5%Ni, 1%Ti, 1%Nb, 0.5%Cr, and the rest are Fe; the composition and proportion of the wear-resistant layer are 15% %Co, 9%Mo, 1%W, 4%WC, 1%TiC, 0.5%Ni, 1%Ti, 1%Nb, 0.5%Cr, and the rest are Fe. The raw material powder, 0.5% B (based on the weight of the components of each layer), 0.5% Si (based on the weight of the components of each layer), and 3% paraffin (based on the weight of the components of each layer) were put into a roller ball mill for wetness. The ball milling medium is anhydrous ethanol, the ball-to-material ratio is 5:1, the ball milling time is 72h, and the ball milling speed is 150r / min. The ball-milled slurry is sprayed and granulated to obtain 80-150 μm powder, and t...

Embodiment 3

[0089] The raw materials are prepared according to the design plan: among them, the composition and proportion of the bottom layer are 15% Co, 8% Mo, 2% W, 2% Ni, 2% Ti, 2% Nb, 2% Cr, and the rest are Fe; the composition of the transition layer and The proportions are 25%Co, 15%Mo, 5%W, 4%WC, 1%TiC, 2%Ni, 2%Ti, 2%Nb, 2%Cr, and the rest are Fe; the composition and proportion of the wear-resistant layer are 25% %Co, 15%Mo, 5%W, 4%WC, 4%NbC, 2%TiC, 2%Ni, 2%Ti, 2%Nb, 2%Cr, and the rest are Fe. The raw material powder, 0.5% B (based on the weight of the components of each layer), 0.5% Si (based on the weight of the components of each layer), and 3% paraffin (based on the weight of the components of each layer) were put into a roller ball mill for wetness. The ball milling medium is anhydrous ethanol, the ball-to-material ratio is 5:1, the ball milling time is 72h, and the ball milling speed is 150r / min. The ball-milled slurry is sprayed and granulated to obtain 80-150 μm powder, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com