Zirconium alloy powder and preparing method thereof

A zirconium alloy and powder technology, which is applied in the field of nuclear power plant pressurized water reactor fuel assembly manufacturing, can solve the problem of failure to consider the hydrogen content, cladding and related parts quality not up to the requirements, zirconium alloy powder particles cannot meet the requirements of nuclear purity grade, etc. problem, achieve the effect of improving fluidity and reducing hydrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

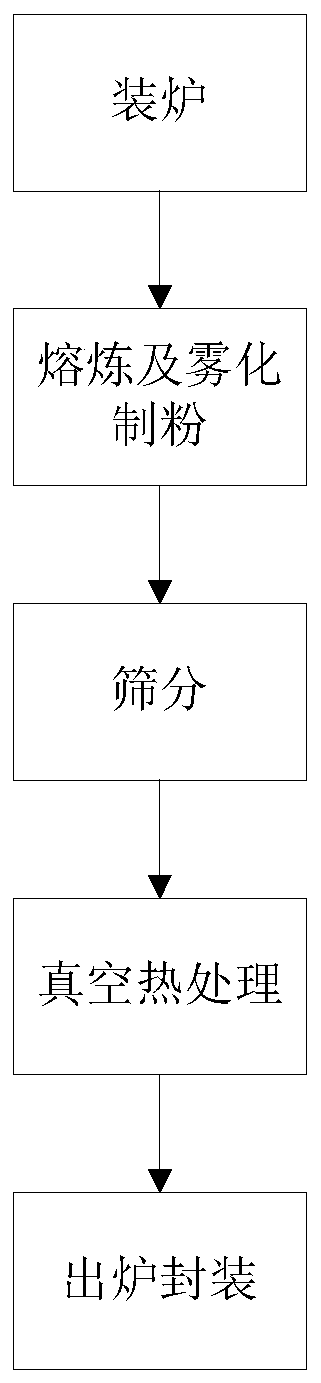

[0042] Such as figure 1 Shown a kind of zirconium alloy powder and preparation method thereof, comprises the following steps:

[0043] (A) Furnace loading, sending the zirconium alloy rod into the atomization furnace, vacuumizing and replacing the inert gas in the atomization furnace;

[0044] (B) smelting and atomizing powder making, heating the zirconium alloy rod until the bottom end of the zirconium alloy rod is melted to form molten droplets, and using inert atomizing gas to crush the molten droplets to form zirconium alloy powder;

[0045] (C) sieving, sieving under a protective atmosphere to obtain zirconium alloy powder with particle size meeting the requirements;

[0046] (D) vacuum heat treatment, sieving the zirconium alloy powder obtained in the heat treatment step (E) in a vacuum heat treatment furnace to obtain a zirconium alloy powder with a hydrogen content lower than 25 μg / g;

[0047] (E) out of the oven packaging;

[0048] In the step (C), the protective a...

Embodiment 2

[0053] On the basis of Example 1, in the step (B), the inert atomizing gas is argon, and the atomization process parameters are: the atomization nozzle pressure is 1.1-1.6 MPa, and the bar feed rate is 12-1.6 MPa. 15cm / min;

[0054] The step (B) includes a preheating stage and a smelting stage. After the preheating stage is completed, adjust the atomizing nozzle pressure to 1.1-1.6 MPa, continue to heat up to the smelting stage, and adjust the atomizing nozzle pressure to 1.4-1.6 MPa after entering the smelting stage , control the bar feeding rate to 12-15cm / min, when the atomizing gas pressure is lower than 1.4MPa, stop atomizing;

[0055] In the preheating stage, the preheating current of the induction coil is 50-60A, and in the melting stage, the melting current of the induction coil is 85-100A.

[0056] The two-stage heating can effectively ensure the continuous and stable zirconium alloy liquid flow. At the same time, according to the different heating temperature sectio...

Embodiment 3

[0058] On the basis of the above examples, in the step (A), after the atomization furnace is evacuated, flush the furnace body with an inert gas for 2 to 3 times, and then fill the furnace body with argon to 80-90kPa; the step ( In A), the surface of the zirconium alloy rod is treated before loading into the furnace; the diameter of the zirconium alloy rod is 10-60 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com