Sludge oxidation pellets and manufacturing method

A technology of sludge oxidation and manufacturing method, applied in blast furnace, furnace type, furnace and other directions, can solve the problems of complex comprehensive utilization process, increased burden, small sludge consumption, etc. The effect of moving forward and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

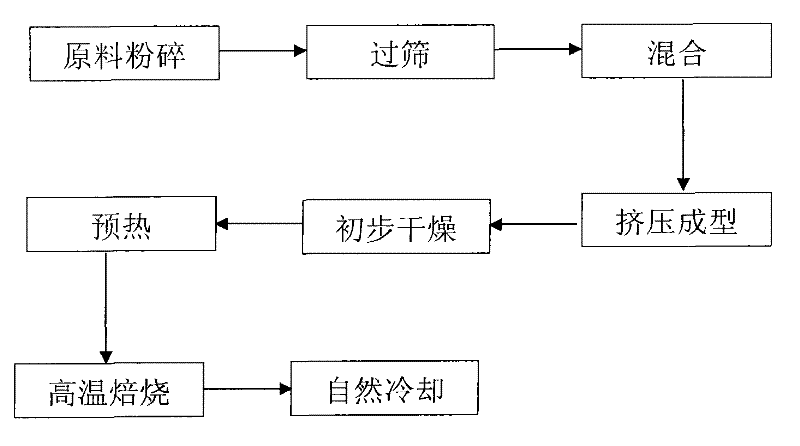

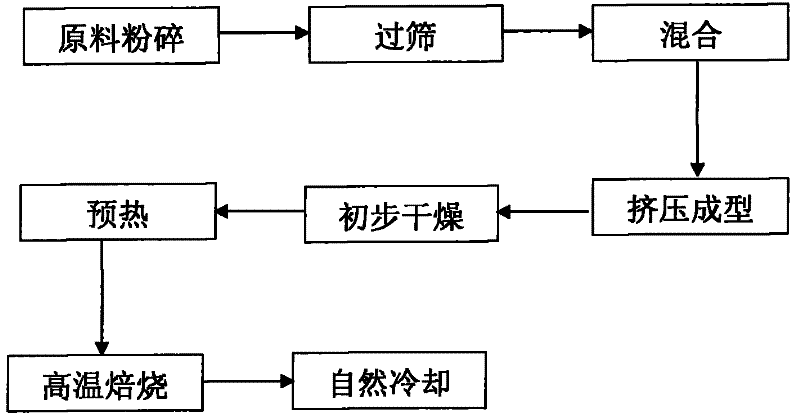

Method used

Image

Examples

Embodiment 1

[0057] After drying and pulverizing the stainless steel cold-rolled heavy metal sludge, 25% of heavy metal sludge (accounting for the weight percentage of the total weight of raw materials for making sludge oxidation pellets, the same below), 50% of iron fine powder, and 4% of carbon powder , 6% of composite binder, 15% of moisture, mix evenly to make green balls, the ball forming pressure is 3500N, and the pellet size is 15mm.

[0058] Among them, the stainless steel cold-rolled heavy metal sludge is the enriched heavy metal sludge produced in the two-step precipitation method of "chemical reduction + liquid soda + lime milk". The chemical composition and weight percentage of the dry base of the stainless steel cold-rolled heavy metal sludge are : T.Fe: 38.5%; Cr 2 o 3 : 3.5%; NiO: 0.5%; CaO: 35.5%; Al 2 o 3 : 3.8%; SiO 2 : 5.4%; CaF 2 : 5.9%; MgO: 0.2%; Na 2 O+K 2 O: 3.6%; S: 2.5%; P<0.1%; the balance is impurities. The detection basis of the aforementioned data: the...

Embodiment 2

[0064]After drying and pulverizing the stainless steel cold-rolled heavy metal sludge, 50% of the heavy metal sludge (accounting for the weight percentage of the total weight of the raw materials for making sludge oxidation pellets, the same below), 30% of iron fine powder, and 5% of carbon powder %, 2% of composite binder, and 13% of moisture, mix uniformly to make green balls, the ball forming pressure is 3000N, and the pellet size is 12.5mm.

[0065] Among them, the stainless steel cold-rolled heavy metal sludge is the enriched heavy metal sludge produced by the two-step precipitation method of "chemical reduction + liquid soda + lime milk". The chemical composition and weight percentage of the dry basis of the stainless steel cold-rolled heavy metal sludge are : T.Fe: 39.8%; Cr 2 o 3 : 4.9%; NiO: 1.0%; CaO: 29.5%; Al 2 o 3 : 2.4%; SiO 2 : 3.5%; CaF 2 : 11.9%; MgO: 0.1%; Na 2 O+K 2 O: 4.6%; S: 1.5%; P<0.1%; the balance is impurities.

[0066] The formula of composit...

Embodiment 3

[0072] After the stainless steel cold-rolled heavy metal sludge is dried and pulverized, according to the formula of 5% of heavy metal sludge (percentage by weight, the same below), 60% of iron fine powder, 15% of carbon powder, 8% of composite binder, and 12% of moisture Ratio, mix evenly to make green pellets, the ball forming pressure is 4000N, and the pellet size is 15mm.

[0073] Among them, the stainless steel cold-rolled heavy metal sludge is the mixed sludge produced by the milk of lime one-step precipitation method, and the chemical composition and weight percentage of the dry base of the stainless steel cold-rolled heavy metal sludge are: T.Fe: 12.5%; Cr 2 o 3 : 2.9%; NiO: 0.4%; CaO: 44.5%; Al 2 o 3 : 4.4%; SiO 2 : 5.2%; CaF 2 : 17.9%; MgO: 0.4%; Na 2 O+K 2 O: 4.5%; S: 4.8%; P: 0.1%; the balance is impurities.

[0074] The formula of the composite binder: 50% of bentonite (percentage by weight, the same below), 15% of slaked lime, 5% of sodium carbonate, 10% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com