Method for preparing glass ceramics by using waste incineration ash synergistic pickling sludge

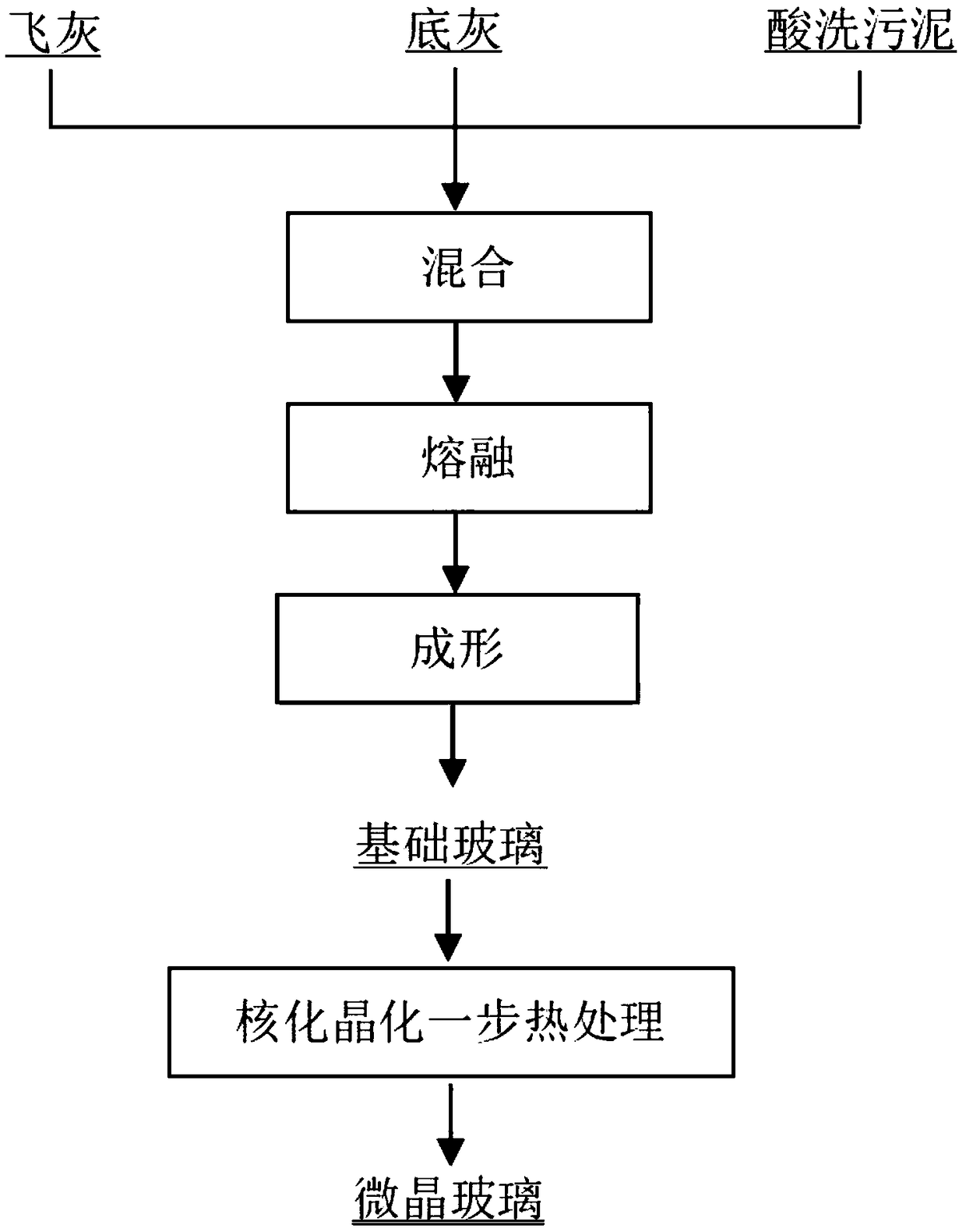

A technology for waste incineration ash and waste incineration fly ash, which is applied in the field of comprehensive utilization of solid waste resources, can solve the problems of high cost, high energy consumption and long process flow of glass-ceramic, and achieves narrowing temperature difference, lowering activation energy, shortening The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The embodiment of the present invention provides a method for preparing glass-ceramic from waste incineration ash and pickling sludge, specifically: mixing 10 wt% of waste incineration fly ash, 80 wt% of bottom ash and 10 wt% of pickling sludge Mixture, where CaO is 4wt%, SiO 2 35wt%, Al 2 o 3 9wt%, K 2 O is 5wt%, Na 2 O is 4wt%, CaF 2 3.5wt%, Fe 2 o 3 6wt%, Cr 2 o 3 0.6wt%. The mixture was heated to 1300°C and then kept for 0.5h to obtain a glass melt. The glass melt is rolled and formed to obtain the basic glass, and after a one-step nucleation and crystallization heat treatment at 800°C for 2 hours, it is cooled to room temperature to obtain a glass-ceramic product.

Embodiment 2

[0032]The embodiment of the present invention provides a method for preparing glass-ceramic from refuse incineration ash and pickling sludge, specifically: mixing 0wt% of refuse incineration fly ash, 80wt% of bottom ash and 20wt% of pickling sludge mixture, where SiO 2 35wt%, Al 2 o 3 12wt%, K 2 O is 4wt%, Na 2 O is 3wt%, CaF 2 8wt%, Fe 2 o 3 4wt%, Cr 2 o 3 is 5wt%. The mixture was heated to 1600° C. and then kept for 1.0 h to obtain a glass melt. The glass melt is calendered to obtain the basic glass, and after a one-step nucleation and crystallization heat treatment at 832°C for 1.0 h, it is cooled to room temperature to obtain a glass-ceramic product.

Embodiment 3

[0034] The embodiment of the present invention provides a method for preparing glass-ceramics by combining refuse incineration ash and pickling sludge, specifically: mixing 11wt% of refuse incineration fly ash, 76wt% of bottom ash and 13wt% of pickling sludge Mixture, where CaO is 4.5wt%, SiO 2 32wt%, Al 2 o 3 15wt%, K 2 O is 4.2wt%, Na 2 O is 3.2wt%, CaF 2 4wt%, Fe 2 o 3 5wt%, Cr 2 o 3 is 4wt%. The mixture was heated to 1370°C and then kept for 2.0 hours to obtain a glass melt. The glass melt is formed by the float method to obtain the basic glass, and after a one-step nucleation and crystallization heat treatment at 864°C for 2.0 hours, it is cooled to room temperature to obtain a glass-ceramic product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com