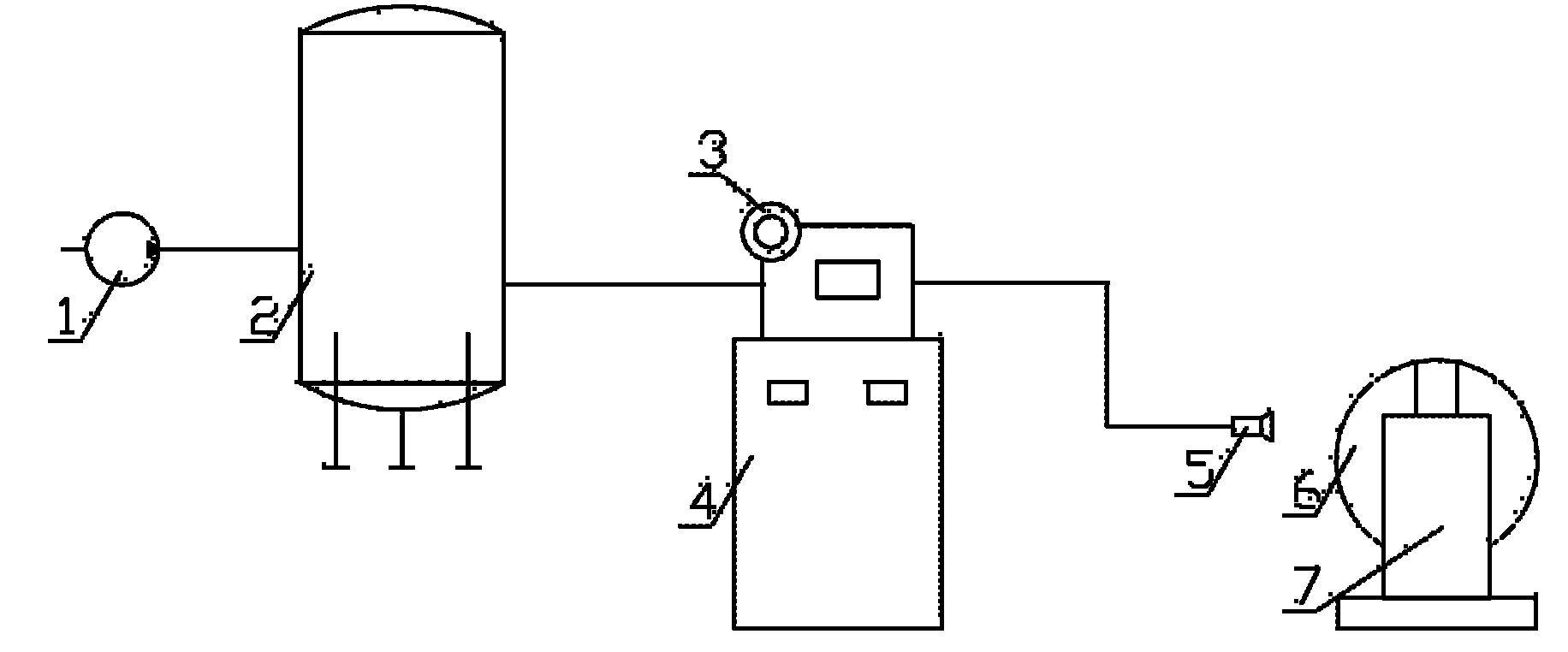

Method for spray-welding anisotropic material on cast iron valve plate

A technology of heterogeneous materials and sealing surfaces, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as cracks easily, achieve the effects of increasing adhesion, reducing production costs, and simple spray welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

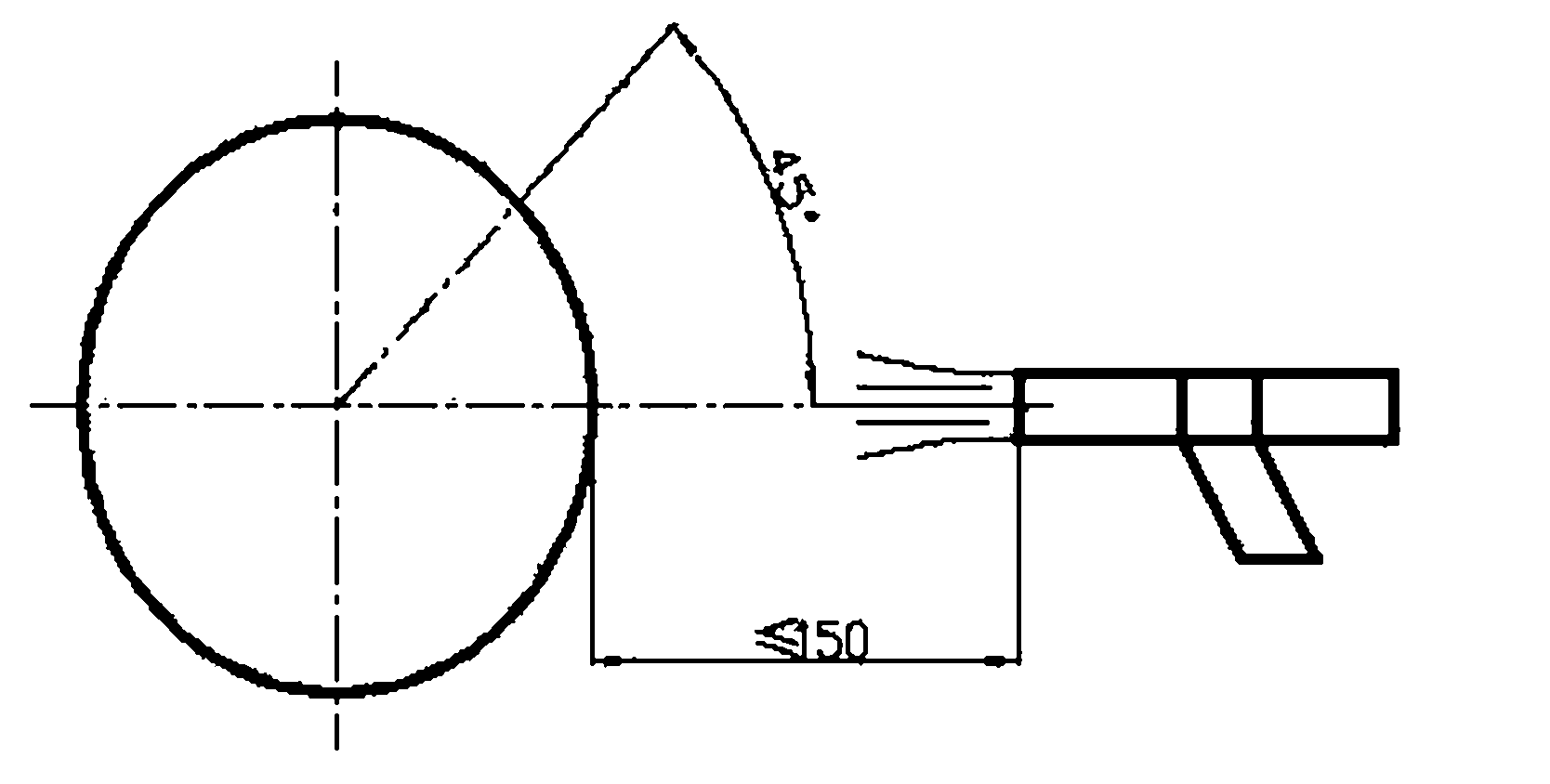

[0008] Below in conjunction with the preferred embodiments, the specific implementation methods provided according to the present invention are described in detail as follows: see the accompanying drawings for details, a method for spray-welding heterogeneous materials on the sealing surface of a cast iron valve plate, the specific process steps are as follows: 1. Valve plate Sorting and checking whether there is oil stain on the spray welding position and the valve plate within 20mm of the adjacent two sides, and place the valve plate with oil stain and the valve plate without oil stain respectively; 2. The sealing surface of the valve plate is polished. The grinding machine grinds off the sharp edges on both sides of the valve plate sealing surface and the sharp edges at the shaft hole orifice to make the sealing plate surface arc transition; 2. Soak the valve plate with synthetic water-based anti-rust cleaning agent After 30 minutes, wash it with clean water and dry it in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com