Method for efficiently smelting Galfan alloy

An alloy and high-efficiency technology, applied in the field of Galfan alloy, can solve the problems of high melting point of rare earth metals, different aluminum content, large difference in the proportion of zinc and aluminum, etc., to achieve accurate and uniform chemical composition, high absorption rate of alloy elements, prevention of burning loss and The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

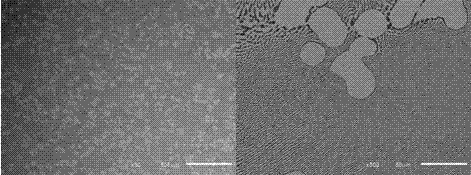

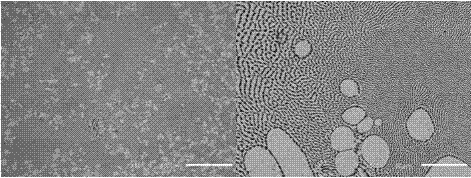

Image

Examples

Embodiment example 1

[0026] Experimentally prepare 300g Zn-5%Al-0.1%Ce alloy, the steps are as follows:

[0027] 1. Melting master alloy

[0028] The composition weight of zinc-rare earth master alloy is as follows:

[0029] Zinc 5.70g

[0030] Rare earth 0.30g

[0031] (1) First accurately weigh the zinc and the rare earth that has been polished off the scale and cleaned with acetone, and vacuum-pack it in a quartz tube to ensure that the rare earth is not oxidized. Put the temperature in the furnace to 500 ° C, and then keep it warm for 2 hours.

[0032] (2) Raise the temperature to 820°C, and then keep the temperature for 5 hours.

[0033] (3) Shake well when sampling to make the composition uniform, and quench.

[0034] 2. Ingredients

[0035] Configure the master alloy, analyze the data, calculate the mass loss, and then calculate the required zinc and aluminum content according to the metal element composition of the target Galfan alloy to ensure accuracy. The composition weight is as f...

Embodiment example 2

[0046] Experimental preparation of 300g Zn-5%Al-0.2%Ce alloy, the steps are as follows:

[0047] 1. Melting master alloy

[0048] Its composition weight percent of zinc-rare earth master alloy is as follows:

[0049] Zinc 11.40g

[0050] Rare earth 0.60g

[0051] (1) First accurately weigh the zinc and the rare earth that has been polished off the scale and cleaned with acetone, and vacuum-pack it in a quartz tube to ensure that the rare earth is not oxidized. Put the temperature in the furnace to 500 ° C, and then keep it warm for 2 hours.

[0052] (2) Raise the temperature to 850°C, and then keep the temperature for 8 hours.

[0053] (3) Shake well when sampling to make the composition uniform, and quench.

[0054] 2. Ingredients

[0055] The master alloy will be configured, the data will be analyzed, and the mass loss will be calculated. Then, according to the metal element composition of the target Galfan alloy, the required zinc and aluminum content will be calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com