Preparation method of aluminum alloy for semiconductor

An aluminum alloy and semiconductor technology, applied in the field of alloys, can solve the problem that the content of impurity elements in the aluminum alloy cannot meet the design requirements, and achieve the effects of improving composition segregation, improving quality and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

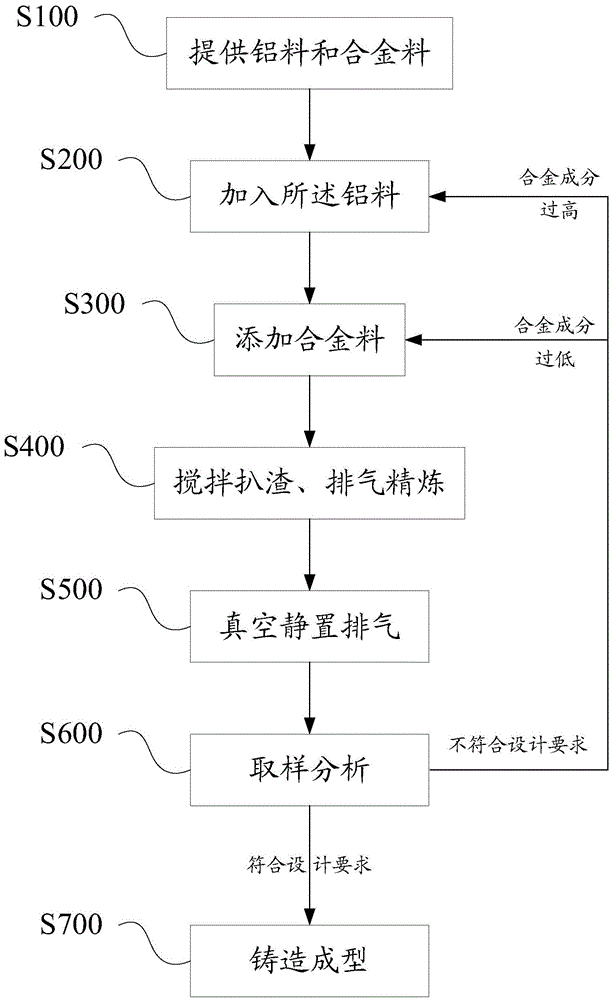

[0039] In order to solve the technical problem, the present invention provides a method for preparing an aluminum alloy for semiconductors, comprising:

[0040] Provide aluminum material and alloy material; melt the aluminum material; add alloy material to the molten aluminum material to form aluminum alloy material, and sequentially carry out stirring and slag removal, exhaust refining; vacuum static exhaust for the aluminum alloy material Processing; sampling and analyzing the aluminum alloy material to determine whether the composition ratio of the aluminum alloy material meets the design requirements; when the composition ratio does not meet the design requirements, add alloy material or aluminum material again according to the analysis results to Make the composition ratio of the aluminum alloy material meet the design requirements, and re-execute the above steps of stirring slag removal, exhaust refining, vacuum static exhaust treatment, and sampling analysis; when the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com