Copper-nickel-iron pipeline connection pipe fitting and preparation thereof

A technology for connecting pipe fittings and pipes, which is applied in the field of copper-nickel-iron pipe connecting pipe fittings and its preparation, and can solve problems such as safety accidents, difficulty in ensuring the normal use of rubber gasket seals, gas or liquid leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

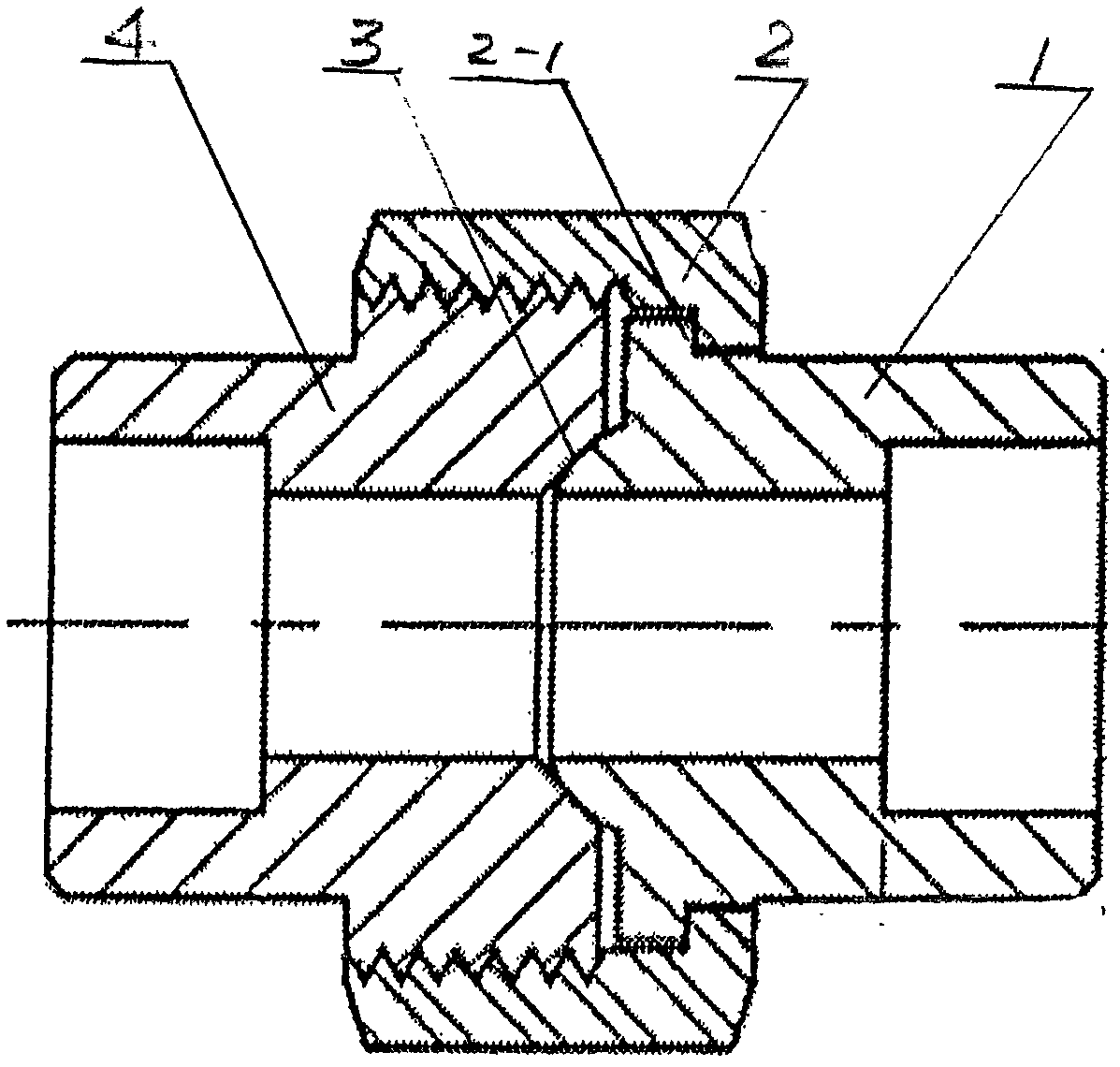

[0006] Below in conjunction with accompanying drawing, take the connecting pipe fitting of copper-nickel-iron alloy as example, the present invention will be further described:

[0007] See attached figure 1 , the mating arc surface 3 of the outer convex joint 1 and the inner concave joint 4 is offset, and the set nut 2 is buckled outside the step 2-1 of the outer convex joint 1 and connected with the thread of the inner concave joint 4 .

[0008] See attached figure 1 , use copper-nickel-iron alloy to add refractory nickel to the bottom, add copper, and then add old materials and covering agent to melt, take samples and analyze, adjust the content of metal elements to meet the composition requirements of copper-nickel-iron alloy, carry out deoxidation refining, when the furnace The temperature rises to the range of 1350-1450°C, remove the slag, add Cu-Mg alloy for deoxidation, and remove the oxygen in the copper liquid; the molten liquid is poured into the mold respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com