Method for smelting rail steel with vanadium-bearing hot metal as raw materials

A technology for rail steel and molten iron, which is applied in the field of rail steel smelting, can solve the problems of wasting heat sources, undiscovered technologies, and increasing costs, and achieves the effects of saving energy, simple operation methods, and reducing smelting costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

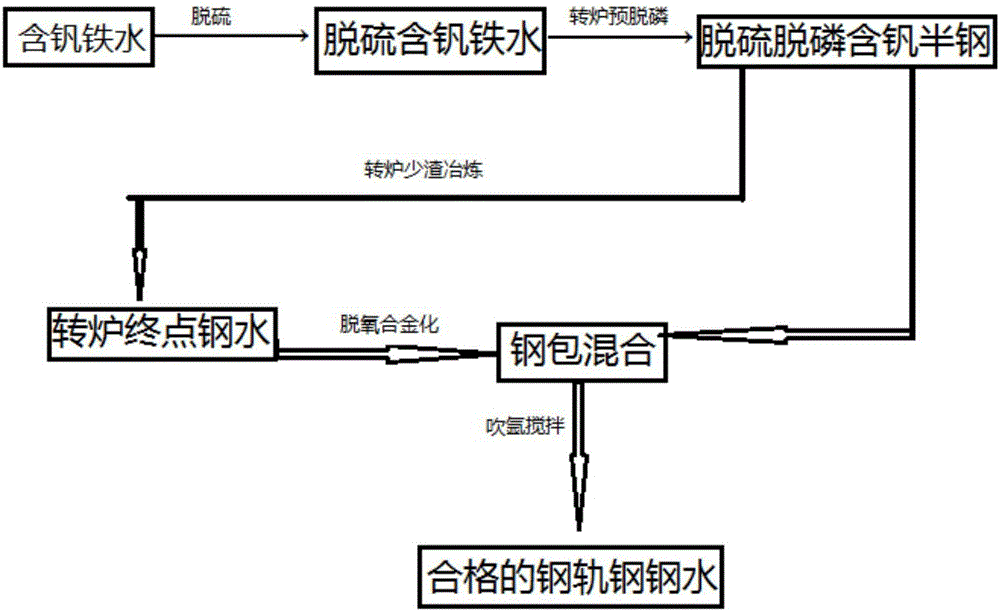

Method used

Image

Examples

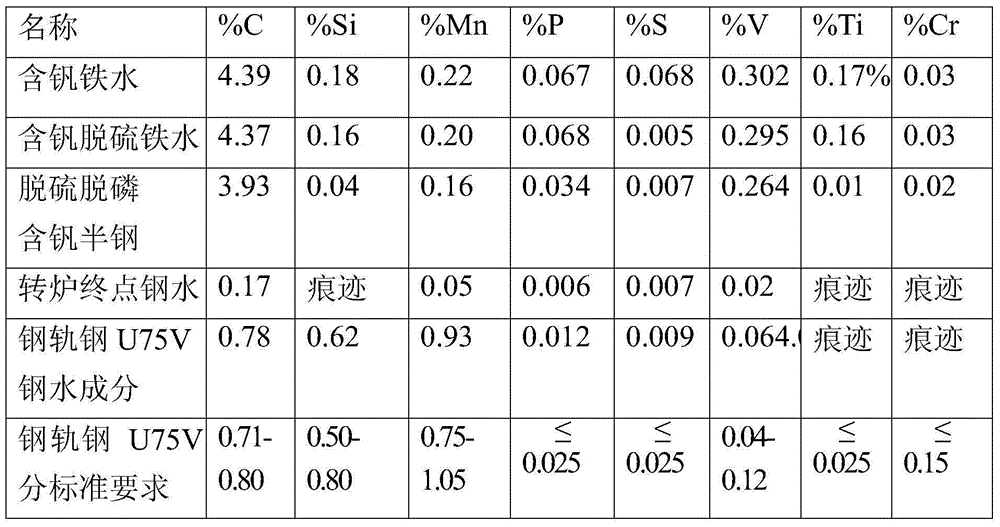

Embodiment 1

[0032] The vanadium-containing hot metal of Panzhihua Iron and Steel Co., Ltd. is used as the raw material. The main components are shown in Table 1. First, deep desulfurization is carried out by combined injection. The injection time is 18.33 minutes. The unit consumption of magnesium powder is 0.91kg per ton of molten iron. After desulfurization, low-sulfur vanadium-containing molten iron is obtained. The main components of low-sulfur vanadium-containing molten iron are shown in Table 1.

[0033] Mix the prepared low-sulfur vanadium-containing molten iron into Panzhihua Iron & Steel's 120t re-blowing steelmaking converter for blowing, the mixing amount is 140t, then add 3.08t of dephosphorization agent into the converter, and use 535 oxygen lance for oxygen dephosphorization , the oxygen pressure is 0.65Mpa, and the oxygen flow rate is 23000m 3 / h, the oxygen supply time was 210 seconds, and then the oxygen supply was stopped. The measured semi-steel temperature was 1423°C, ...

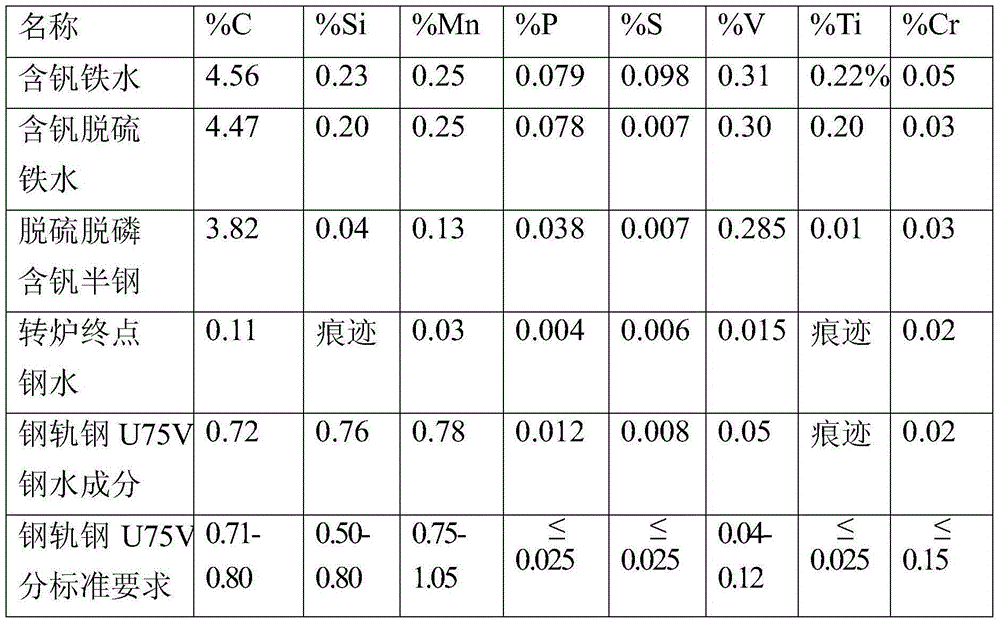

Embodiment 2

[0040]Using Panzhihua Iron and Steel Vanadium-containing molten iron as raw material, its main components are shown in Table 2. Through composite injection deep desulfurization, the injection time is 24.66min, and the unit consumption of desulfurizer lime is 4.2kg per ton of vanadium-containing molten iron. The unit consumption of magnesium powder is 1.0kg per ton of vanadium-containing hot metal. After desulfurization, low-sulfur vanadium-containing hot metal is obtained. The main components of low-sulfur vanadium-containing hot metal are shown in Table 2.

[0041] Mix the prepared low-sulfur vanadium-containing molten iron into Panzhihua Iron & Steel's 120t re-blowing steelmaking converter for blowing, the mixing amount is 140t, then add 3.5t of dephosphorization agent into the converter, and use 535 oxygen lance for oxygen dephosphorization , the oxygen pressure is 0.65Mpa, and the oxygen flow rate is 23000m 3 / h, the oxygen supply time was 240 seconds, and then the oxygen ...

Embodiment 3

[0048] Using Panzhihua Iron and Steel Vanadium-containing molten iron as raw material, its main components are shown in Table 3. Through combined injection deep desulfurization, the injection time is 17 minutes, the unit consumption of desulfurizer lime is 3.5kg per ton of vanadium-containing molten iron, and the desulfurizer passivates magnesium The unit powder consumption is 0.9kg per ton of vanadium-containing hot metal. After desulfurization, low-sulfur vanadium-containing hot metal is obtained. The main components of low-sulfur vanadium-containing hot metal are shown in Table 3.

[0049] Mix the prepared low-sulfur vanadium-containing desulfurized hot metal into Panzhihua Iron and Steel's 120t double blowing steelmaking converter for blowing. Phosphorus, oxygen pressure is 0.60Mpa, oxygen supply flow is 23000m 3 / h, the oxygen supply time was 210 seconds, and then the oxygen supply was stopped. The measured semi-steel temperature was 1425°C, and the desulfurized and depho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com