Method and device for disposing waste incineration fly ash in low-energy-consumption, recycling and environment-friendly manner

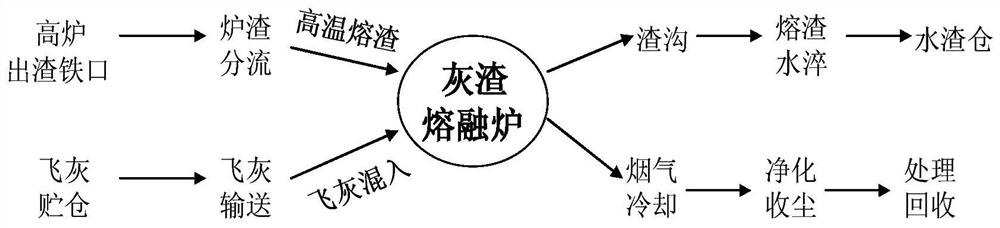

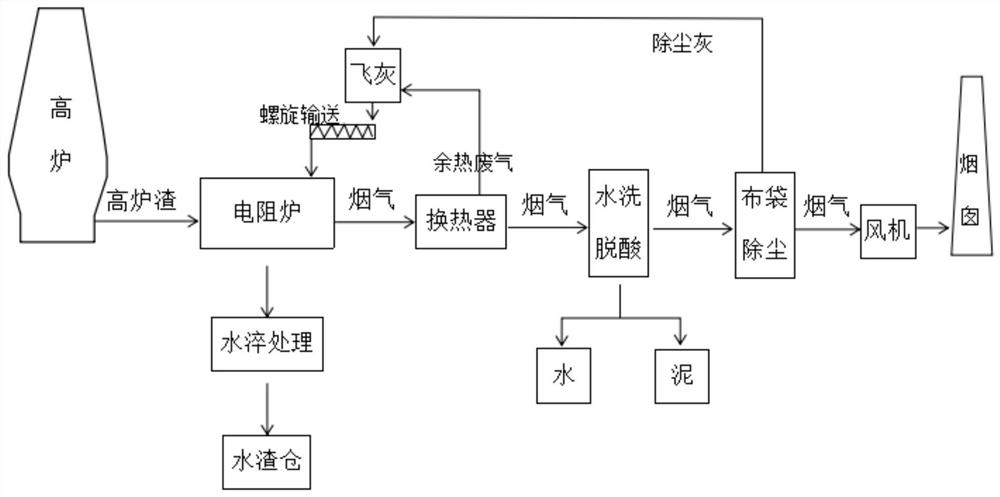

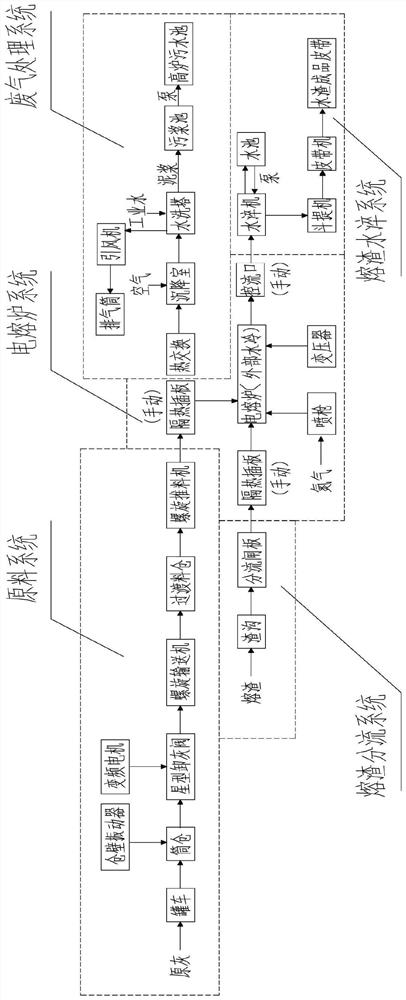

A waste incineration fly ash and recycling technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of secondary volatilization pollution of heavy metals, poor resource utilization effect, high energy consumption of melting treatment, etc., to reduce disposal costs , Reduce the cost of fly ash disposal, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Turn on the dust removal system fan and run the dust removal system equipment. The molten slag discharged from the blast furnace is divided into a melting furnace that has been heated to above 1400°C and filled with blast furnace slag and the liquid level is above the specified lower limit. The temperature of the blast furnace slag is 1500°C. Fly ash is discharged into the melting furnace later, and as the liquid level of blast furnace slag in the melting furnace rises, the flow rate of fly ash can be gradually increased. The negative pressure of the control system makes the pressure of the flue gas outlet on the top of the melting furnace a slight negative pressure. When the weight or liquid level of blast furnace slag in the melting furnace reaches a certain set value, the discharge of blast furnace slag is stopped. Stop adding fly ash when the amount of fly ash discharged reaches 15% of the total mass of blast furnace slag and fly ash. The melting furnace is contin...

Embodiment 2

[0064] Turn on the dust removal system fan and run the dust removal system equipment. The molten slag discharged from the blast furnace is divided into the melting furnace whose temperature has been raised above 1400°C, and the temperature of the blast furnace slag is 1505°C. Later, the fly ash is discharged into the melting furnace. As the liquid level of the blast furnace slag in the melting furnace rises, the flow rate of the fly ash is gradually increased. The negative pressure of the control system makes the pressure of the flue gas outlet on the top of the melting furnace a slight negative pressure. When the weight or liquid level of blast furnace slag in the melting furnace reaches a certain set value, the discharge of blast furnace slag is stopped. Stop adding fly ash when the amount of fly ash discharged reaches 20% of the total mass of blast furnace slag and fly ash. The melting furnace is continuously heated while the fly ash is discharged into the melting furnace...

Embodiment 3

[0067] Turn on the dust removal system fan and run the dust removal system equipment. The slag in the molten state discharged from the blast furnace is divided into the melting furnace that has been heated to above 1400°C, and the temperature of the blast furnace slag is 1510°C. Later, the fly ash is discharged into the melting furnace, and as the liquid level of the blast furnace slag in the melting furnace rises, the flow rate of the fly ash can be gradually increased. The negative pressure of the control system makes the pressure of the flue gas outlet on the top of the melting furnace a slight negative pressure. When the weight or liquid level of blast furnace slag in the melting furnace reaches a certain set value, the discharge of blast furnace slag is stopped. Stop adding fly ash when the amount of fly ash discharged reaches 25% of the total mass of blast furnace slag and fly ash. The melting furnace is continuously heated while the fly ash is discharged into the melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com