Regeneration preparation method for copper-containing aluminium alloy through aviation industry aluminium alloy waste materials

A technology of aviation industry and aluminum alloy, which is applied in the field of circular economy technology and environmental protection, to achieve the effect of saving recycling cost, high use value, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

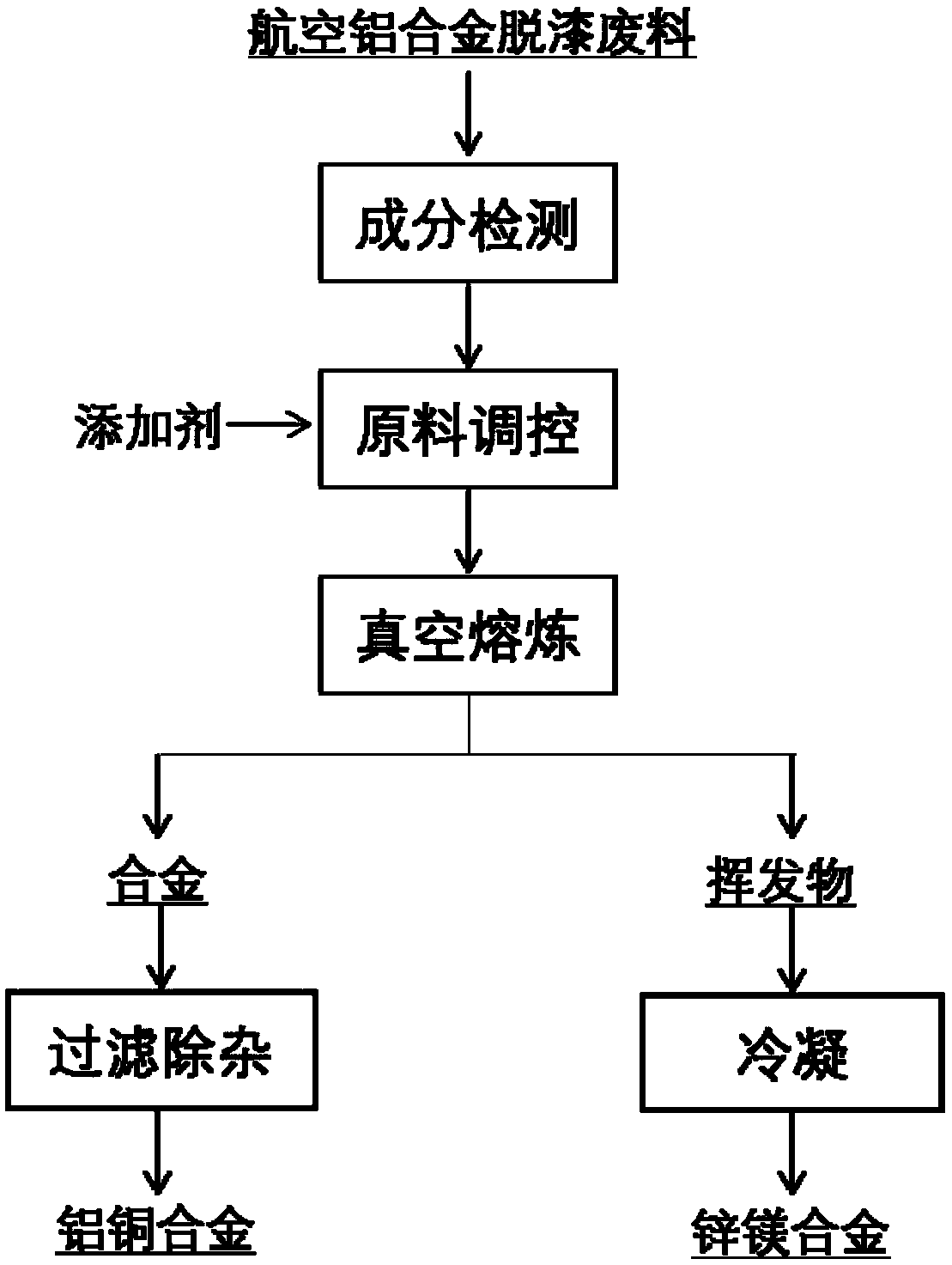

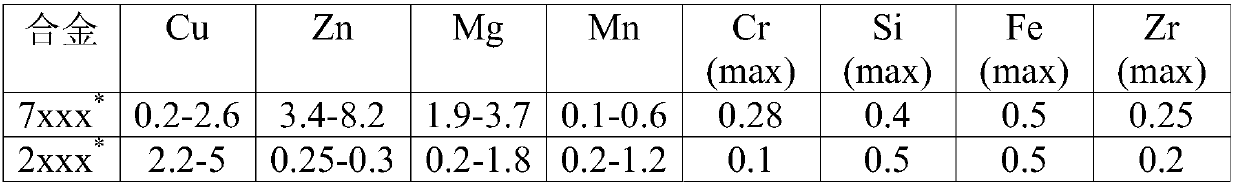

Method used

Image

Examples

Embodiment 1

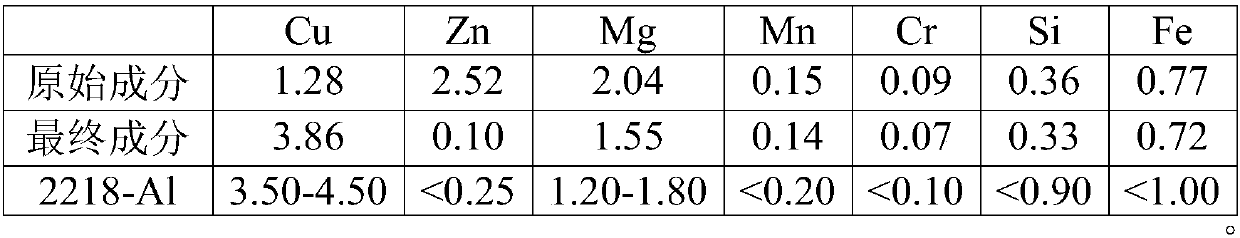

[0039] Take a proper amount of paint stripping treatment and simply melt the aviation aluminum alloy waste. After ICP-OES detection, the main alloy components of the original aluminum alloy are shown in Table 2.

[0040] According to the composition requirements of the target alloy 2024 aluminum alloy, pure copper with a mass fraction of 0.8% was weighed and added to the mixed alloy.

[0041] Put the material into a high-purity graphite crucible, vacuumize the induction furnace until the internal pressure is lower than 30Pa, heat and melt in the induction furnace with a built-in graphite condensation plate, and the temperature is 780 °C. Control the frequency of the induction furnace to realize the stirring of the melt. During this process, zinc and magnesium leave the aluminum alloy melt in the form of steam, and volatilize and condense on the condensation plate placed on the upper part of the melt.

[0042] After 60 minutes, the aluminum alloy solution is filtered with a cera...

Embodiment 2

[0047] Take a proper amount of paint stripping treatment and simply melt the aviation aluminum alloy waste. After ICP-OES detection, the main alloy components of the original aluminum alloy are shown in Table 3.

[0048] According to the composition requirements of the target alloy 2014 aluminum alloy, the copper-magnesium alloy with a mass fraction of 2.5% was weighed and added to the mixed alloy.

[0049] Put the material into a high-purity graphite crucible, evacuate the induction furnace until the internal pressure is lower than 25Pa, heat and melt in the induction furnace with a built-in graphite condensation plate, and the temperature is 900 °C. Control the frequency of the induction furnace to realize the stirring of the melt. During this process, zinc and magnesium leave the aluminum alloy melt in the form of steam, and volatilize and condense on the condensation plate placed on the upper part of the melt.

[0050] After 120 minutes, the aluminum alloy solution was fi...

Embodiment 3

[0055] Take a proper amount of paint stripping treatment and simply melt the aviation aluminum alloy waste. After ICP-OES detection, the main alloy components of the original aluminum alloy are shown in Table 4.

[0056] According to the composition requirements of the target alloy 2219 aluminum alloy, the copper-chromium alloy with a mass fraction of 3.0% was weighed and added to the mixed alloy.

[0057] Put the material into a high-purity graphite crucible, evacuate the induction furnace until the internal pressure is lower than 10Pa, heat and melt in the induction furnace with a built-in graphite condensation plate, and the temperature is 1030°C. Control the frequency of the induction furnace to realize the stirring of the melt. During this process, zinc and magnesium leave the aluminum alloy melt in the form of steam, and volatilize and condense on the condensation plate placed on the upper part of the melt.

[0058] After 180 minutes, the aluminum alloy solution was fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com