Method for producing nickel-iron alloy by smelting red earth nickel mineral at low temperature

A technology of laterite nickel ore and nickel-iron alloy, which is applied in the field of low-temperature smelting of laterite nickel ore to produce nickel-iron alloy, which can solve the problems of corroded furnace lining, difficult separation of slag and iron, and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

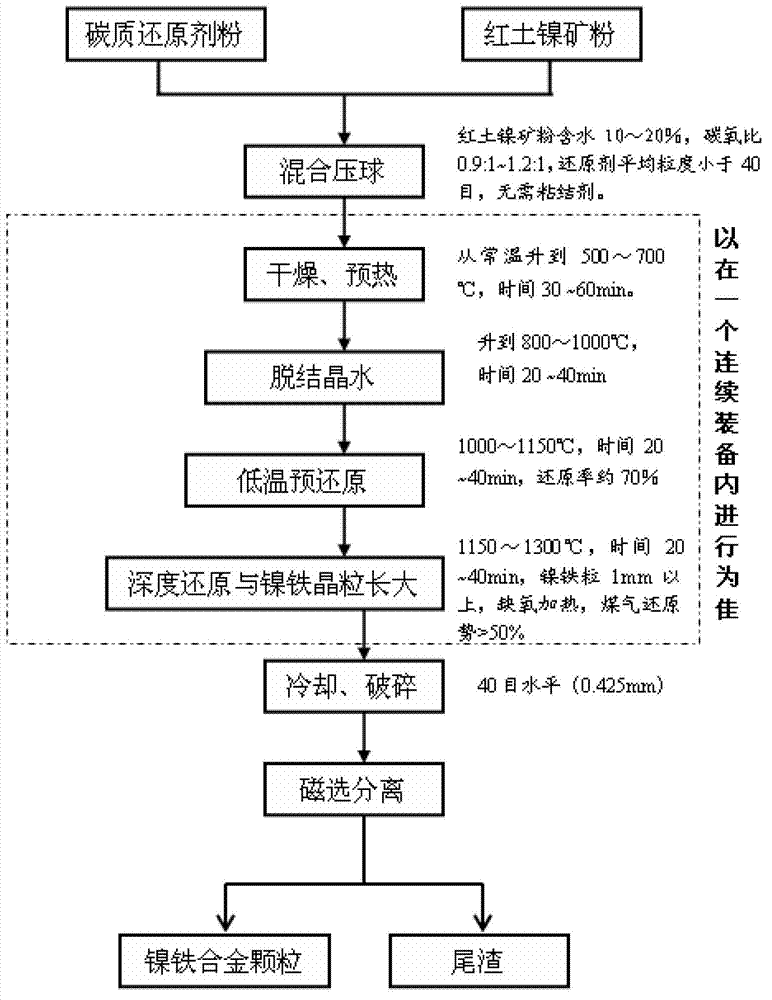

Image

Examples

Embodiment 1

[0046] The composition of the laterite nickel ore used in Example 1 is shown in Table 1, and the reducing agent is coke powder, and the composition is shown in Table 2.

[0047] Table 1 The main chemical components of laterite nickel ore / wt%

[0048] TF

[0049] Table 2 Main components of coke powder / wt%

[0050] fixed carbon

[0051] The equipment used is a hammer crusher with a production capacity of 1.5t / h and a power of 2.2kw, a mixing and pressing ball machine with a power of 15kw, and the smelting device is an integrated device, which is divided into drying, preheating, decrystallization water, In the stages of low-temperature pre-reduction, deep reduction, nickel-iron grain growth, and cooling, the maximum smelting capacity is 1t / h, and 5000kJ / m is used in the low-temperature pre-reduction section 3 Natural gas heating is used, and natural gas anoxic heating is used for deep reduction and ferronickel grain growth. After cooling, the crushing equipm...

Embodiment 2

[0062] The composition of the laterite nickel ore used in Example 2 is shown in Table 5, which is a typical low-grade laterite nickel ore. The reducing agent is anthracite, and its composition is shown in Table 6. First, the laterite nickel ore powder containing 10-20wt% of physical water and the anthracite coal powder with an average particle size of 40 mesh are mixed according to the carbon-to-oxygen ratio of 1.1:1 and pressed into balls to obtain an elliptical ball with a length of about 50mm and a width of about 20mm.

[0063] Table 5 Chemical composition of laterite nickel ore powder / wt%

[0064] TF

[0065] Table 6 Chemical composition of anthracite / wt%

[0066] fixed carbon

[0067] The equipment used is the same as in Example 1, and what is slightly adjusted is that electric heating is used in the stage of deep reduction and ferronickel grain growth, so that it can be ensured that in the atmosphere of this stage (CO+H 2 ) / (CO+H 2 +H 2 O+CO 2 )>...

Embodiment 3

[0075] Similar to Example 1, but adding 10% CaO to the laterite nickel ore powder to remove part of the physical water, adding coke powder at a carbon-to-oxygen ratio of 0.95:1, and adding a total of 2% of the mixed binder. Other smelting parameters are the same as in Example 1. A qualified nickel-iron alloy can also be obtained, the composition of which is similar to that of the nickel-iron alloy in Example 1, and the CaO content in the slag is significantly higher than that in Example 1 (see Table 9).

[0076] Table 9 The main components of slag / wt%

[0077] Cr

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com