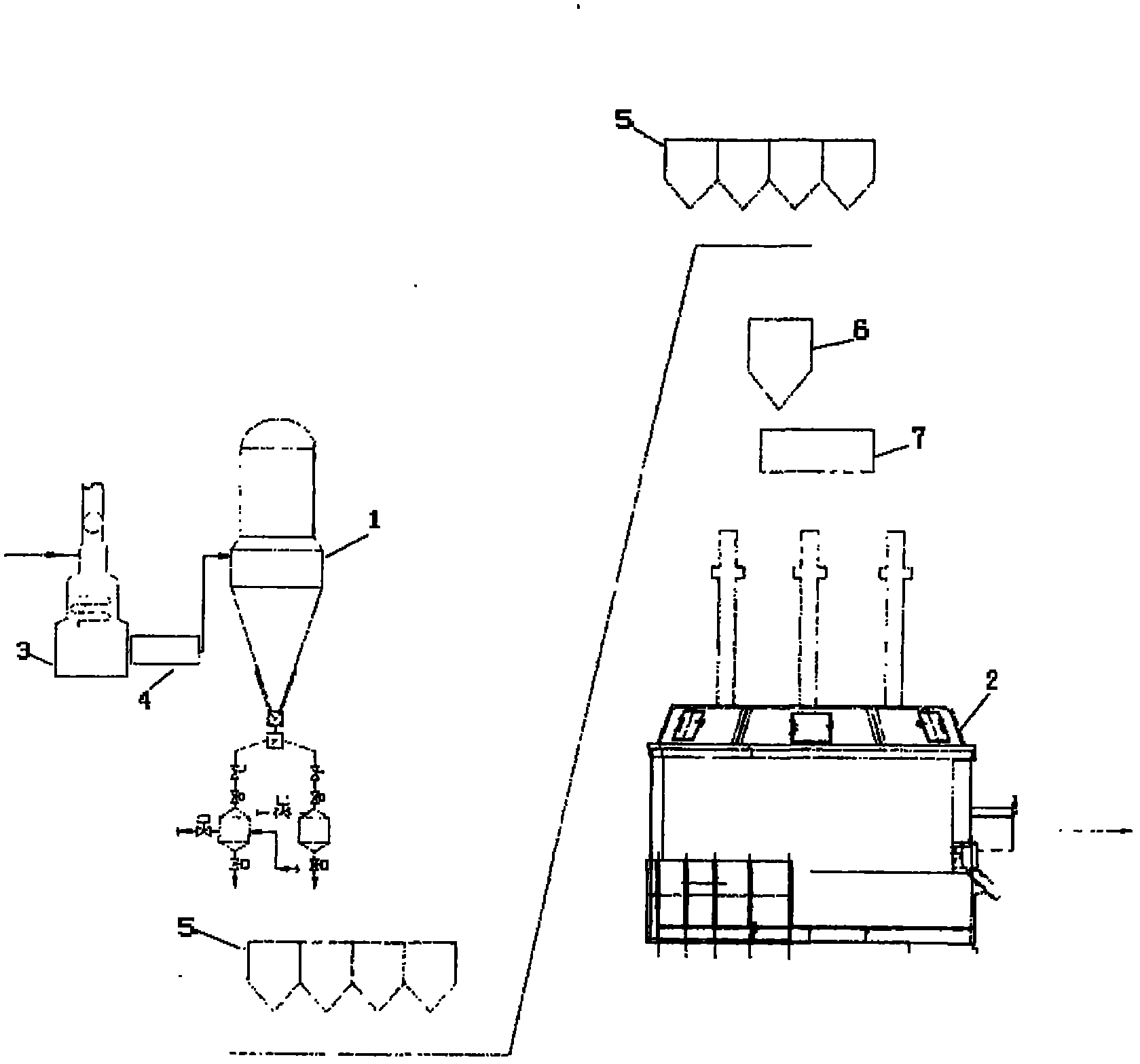

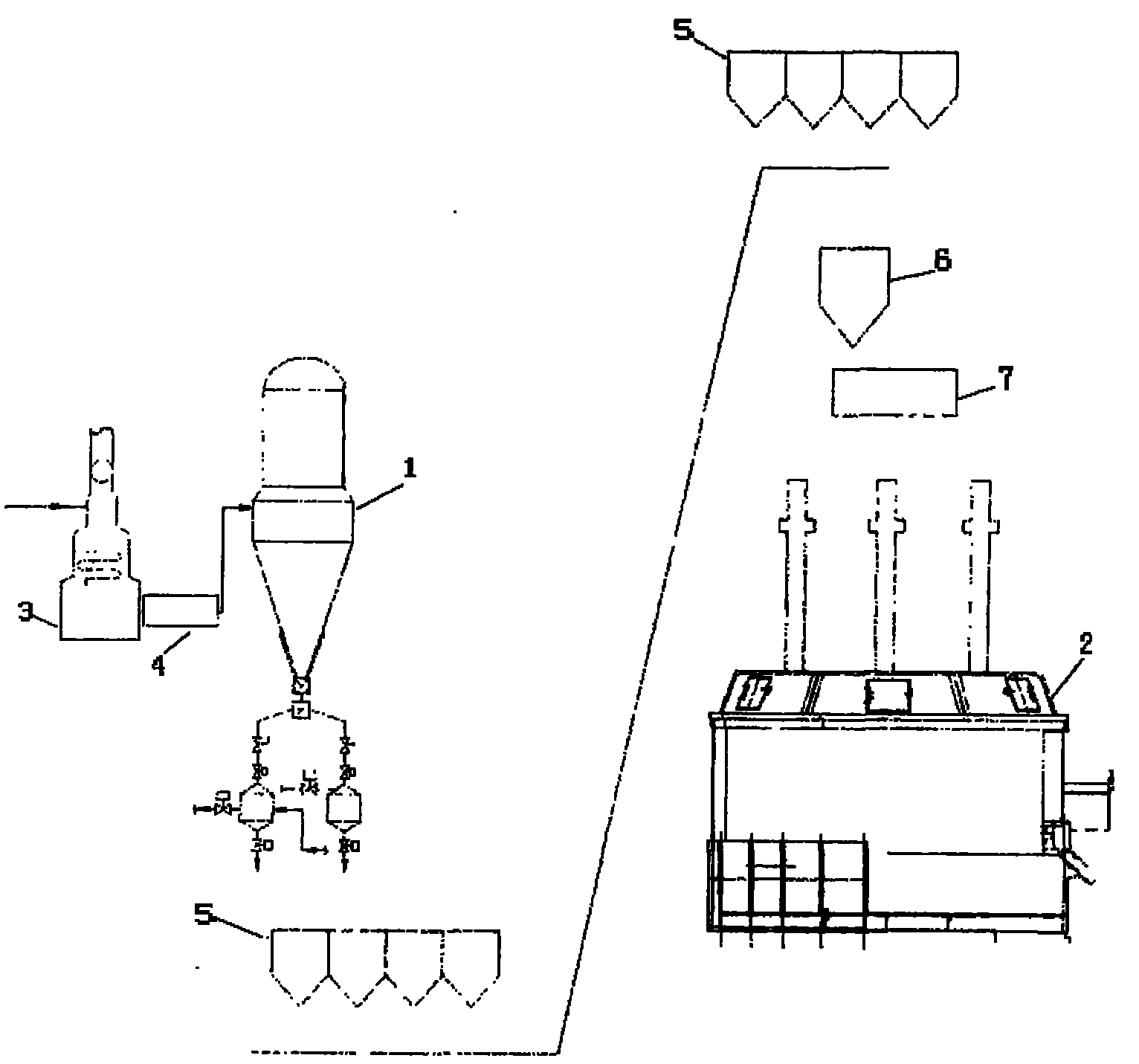

Iron making method and device by virtue of gas-based smelting reduction

A gas-based, gas-based technology, applied in the direction of reducing gas emissions, can solve the problems of difficult raw material sources, difficult reduction process, and high requirements for reduction equipment, and achieve the effects of improving equipment utilization, low cost, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The raw material used in this embodiment is pellets, and its chemical composition is as shown in Table 1

[0058] Table 1: pellet chemical composition: (the unit of numerical value in the table is weight percent)

[0059] TF

FeO

S

P

SiO 2

63.00

0.10

0.006

0.023

7.21

[0060] TFe represents the total iron content, that is, the total amount of iron in the ore.

[0061] The reducing gas used in this example is the by-product gas produced by semi-coke, and its chemical composition is shown in Table 2.

[0062] Table 2 (the units of the values in the table are volume percentages)

[0063] name

H 2

CO

CO 2

CH 4

C n h m

h 2 o

content

47.12

34.84

2.1

11.18

1.65

3.1

[0064] Gas calorific value is about: 15900KJ / Nm 3

[0065] Process conditions for gas-based shaft furnace reduction:

[0066] Ore gas ratio (p...

Embodiment 2

[0072] The raw materials used in this embodiment are the same as in Example 1, and the specific process is as follows.

[0073] The above-mentioned by-product gas (reducing gas) is passed into the inner side of the tubes in the tube-and-tube heat exchanger 3, and the high-calorie tail gas produced by the reduction tail gas of the combustion shaft furnace is passed into the outer side of the tubes, and the high-calorie tail gas exchanges heat with the by-product gas , the reducing gas is heated to 800°C-850°C. Then, the reducing gas is passed into the burner 4, and oxygen is injected from the combustion nozzle, and the oxygen partially burns the reducing gas, and supplementarily increases the temperature of the reducing gas to 950-970°C. The feed rate of oxygen is 3%-4% (volume ratio) of the reducing gas.

[0074] Preheat the pellets to 650°C-700°C. Then, the above-mentioned pellets and reducing gas are mixed according to the ore gas ratio (pellets (kg): coal gas (Nm 3 )) = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com