Solid phase microextraction method of unsaturated fatty acid

An unsaturated fatty acid and extraction technology, applied in the field of analytical chemistry, can solve problems such as indistinguishability, qualitative and quantitative analysis effects, etc., and achieve the effect of simple method, improved separation degree and ingenious process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

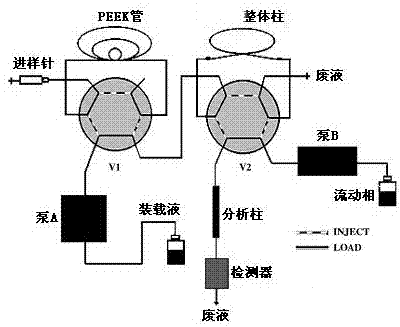

Method used

Image

Examples

preparation example Construction

[0032] 1. Preparation of mucopolysaccharide functionalized monolithic column:

[0033] 1) Cleaning of PTFE tube empty column: Connect a PTFE tube with an inner diameter of 750 μm to a liquid phase pump, wash it with chromatographically pure methanol at a flow rate of 0.5 mL / min for 10 min to remove residual organic impurities on the inner wall of the tube, and then pass nitrogen gas. and dried in an oven at 60 °C for 10 min.

[0034]2) Rapid polycondensation in the tube: Mix 8 mg sodium hyaluronate, 550 mg 1 g / mL urea solution, 450 mg formaldehyde solution, and 100 mg 0.2 mol / L hydrochloric acid solution evenly, and oscillate rapidly for 1 to 2 min, and then dissolve the mixture Quickly fill the cleaned and dried PTFE tube (or PEEK tube), seal both ends and immerse in a water bath at 70 °C for 10 min at a constant temperature; after the reaction is completed, use water as the mobile phase and rinse the PTFE tube on the liquid chromatography pump Keep the monolithic column for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com