Two-dimensional titanium carbide supported stable biphase molybdenum diselenide composite material and preparation method and application thereof

A two-dimensional titanium carbide and molybdenum diselenide technology, applied in electrolytic components, electrodes, nanotechnology, etc., can solve the problems of high cost and poor stability of electrocatalytic hydrogen evolution catalysts, achieve good charge conductivity, improve electrical conductivity, Prevent stacking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

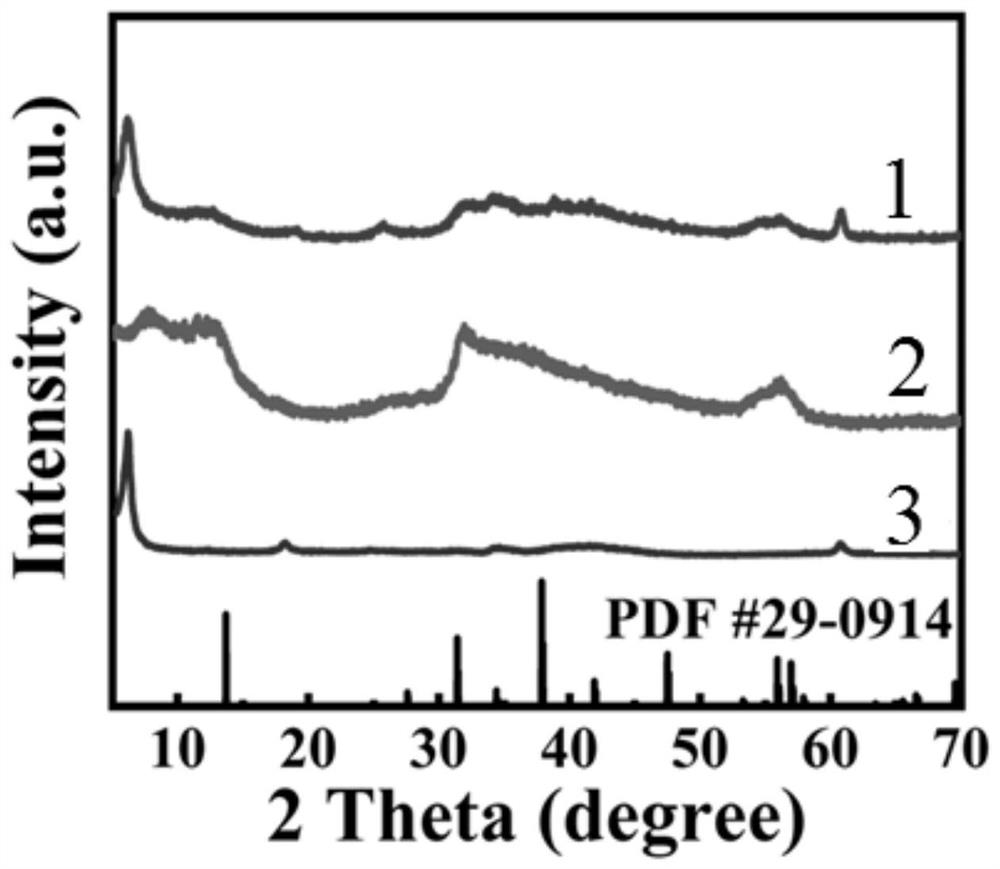

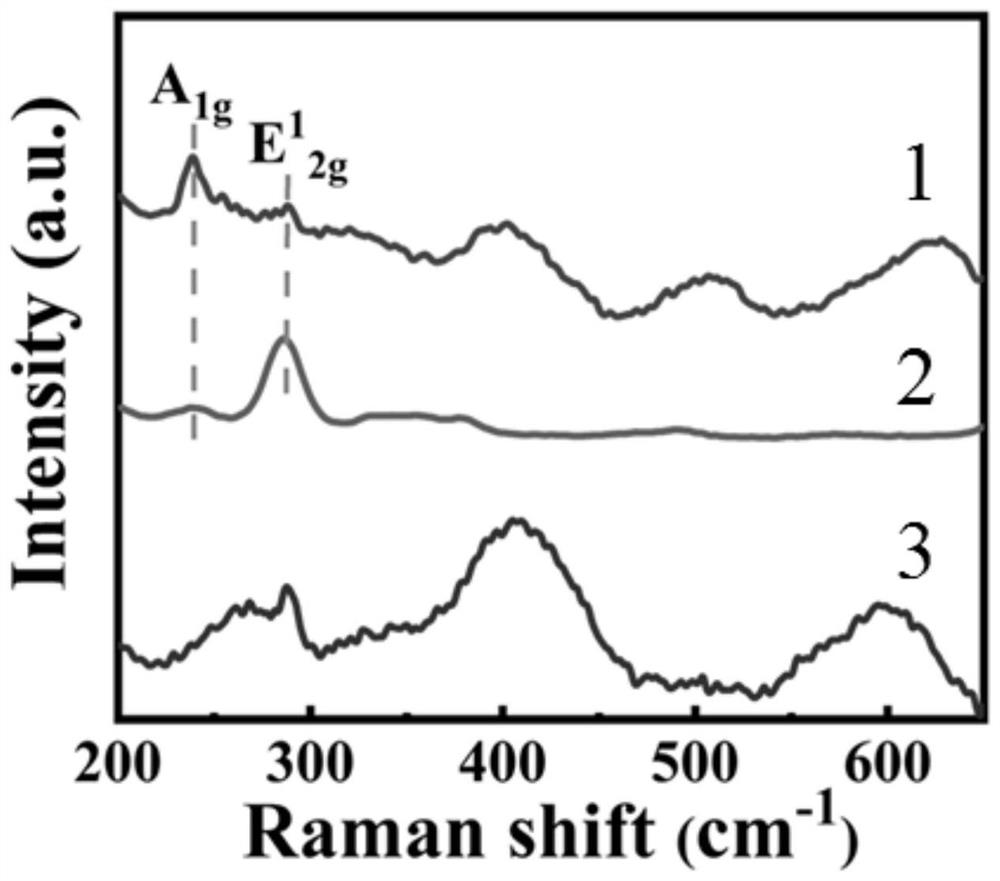

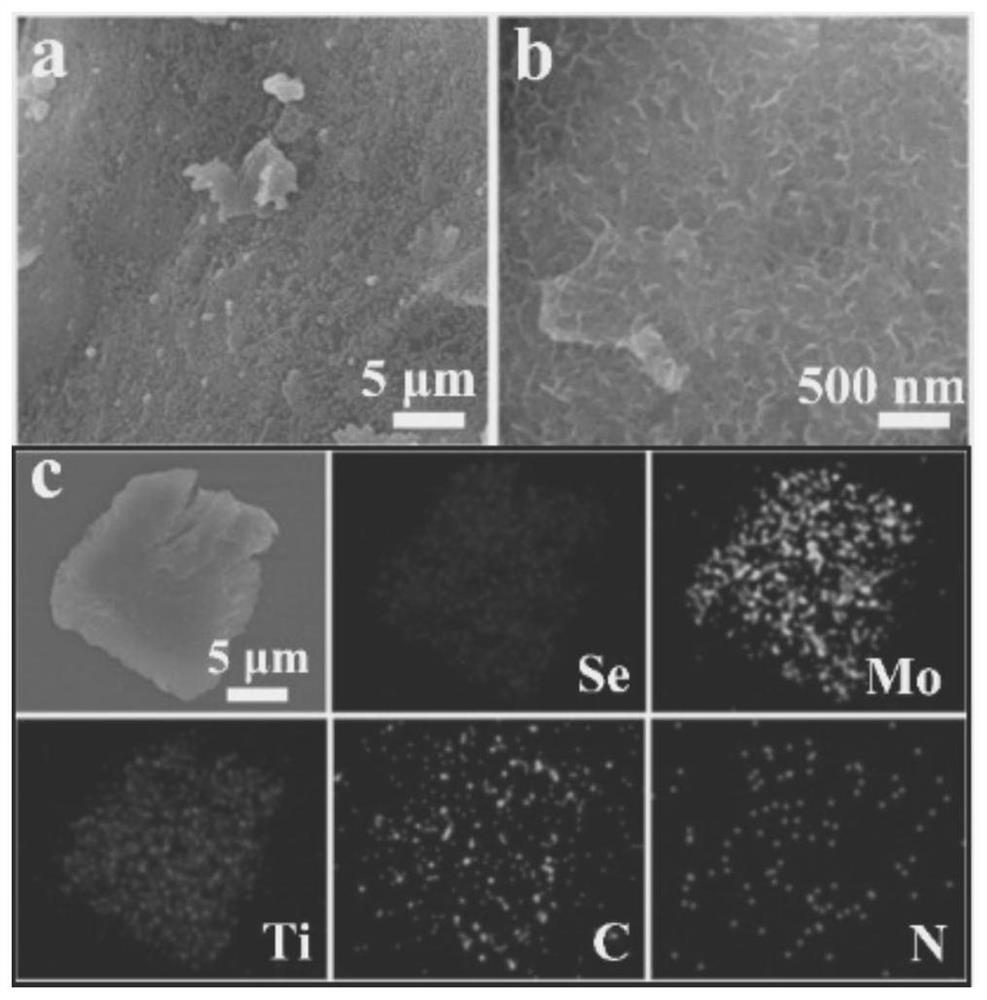

[0031] Specific Embodiment 1: In this embodiment, a two-dimensional titanium carbide-supported stable dual-phase molybdenum diselenide composite material contains 0.2% to 5% of N elements at an atomic percentage, and titanium carbide is used as MoSe 2 The conductive framework of nanosheets forms a three-dimensional interconnected network structure, MoSe 2 Nanosheets are uniformly grown in situ on the TiC surface; the MoSe 2 The nanosheet is only 1-10 Mo atomic layers thick, and its 002 crystal plane spacing is 0.65-1.00nm, which is a dual-phase coexistence structure of 2H and 1T.

specific Embodiment approach 2

[0032] Specific embodiment two: This embodiment is a preparation method of a stable two-phase molybdenum diselenide composite material supported by two-dimensional titanium carbide, which is completed according to the following steps:

[0033] 1. Na 2 MoO 4 2H 2 O was dissolved in a mixed solution of absolute ethanol and deionized water, stirred until the solution was clear, and then a thin layer of Ti was added 3 C 2 , sonicated to get Na 2 MoO 4 -Ti 3 C 2 solution;

[0034] 2. Add Se powder to N 2 h 4 ·H 2 O solution, and then stirred at a temperature of 20°C to 80°C until the solution turned dark red to obtain Se-N 2 h 4 solution;

[0035] 3. Na 2 MoO 4 -Ti 3 C 2 The solution was added dropwise to Se-N 2 h 4 solution, to obtain a mixed solution; transfer the mixed solution to a polytetrafluoroethylene kettle, and then perform a hydrothermal reaction to obtain a reaction product; wash the reaction product, and then dry it to obtain a two-dimensional titani...

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the Na described in step one 2 MoO 4 2H 2 The mass ratio of O to the mixed solution of absolute ethanol and deionized water is (0.1g-0.2g): 100mL. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com