High-strength, high-toughness, wear-resistant steel for excavator bucket teeth and manufacturing method thereof

A technology for excavator bucket teeth and toughness, which is applied in the field of alloy structural steel, can solve problems such as not being able to meet the needs of environmental excavator bucket teeth, and achieve the effect of excellent microstructure and internal steel quality, high toughness, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The low-carbon silicon-manganese-molybdenum-vanadium alloy steel of the present invention is smelted by UHP (ultra-high-power electric furnace), LF (external furnace refining), VD vacuum degassing treatment process, through full-protection casting and continuous casting, and hot-rolled into material. The embodiment specifically illustrates how the present invention is implemented with the production of Φ80mm specification round steel.

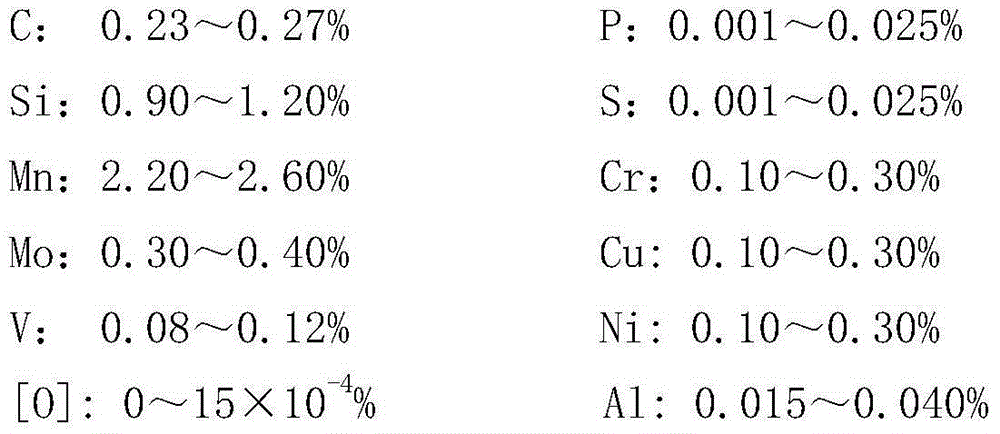

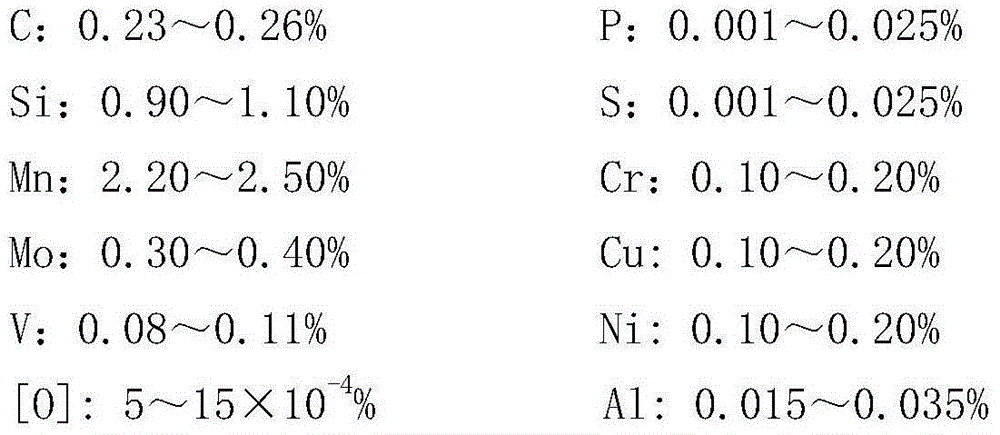

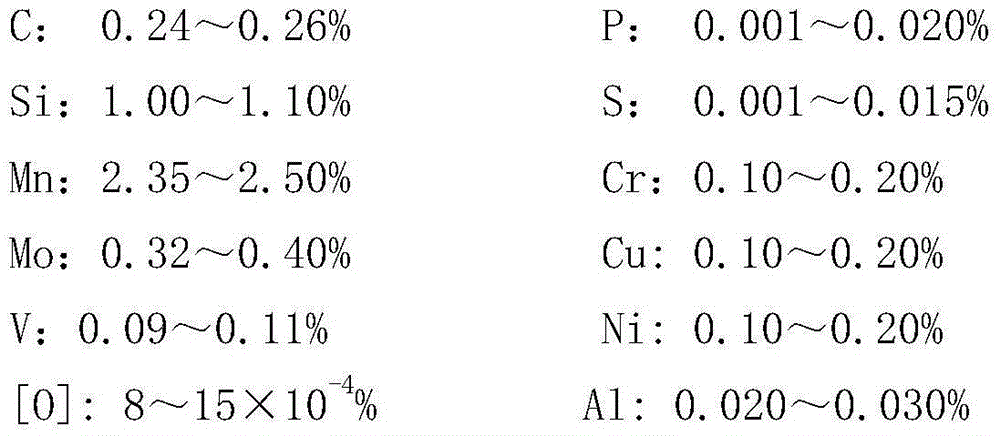

[0043] The preparation method of low-carbon silicon-manganese-molybdenum-vanadium alloy steel for excavator bucket teeth, the composition of the steel is as described in Table 1, and the steps are as follows:

[0044] (1) Smelting and alloying, using electric furnace smelting, the end point [C]≥0.10%, P≤0.012%, the content of residual elements meets the design requirements, and the temperature of molten steel reaches 1630~1660℃ for tapping; LF refining outside the furnace, refining slag Alkalinity is controlled at 3.0-3.4; white slag ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Charpy impact | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com