Online continuous caster outer arc segment row arc measurement method

A measuring method and technology of external arc rolls, applied in the direction of measuring devices, instruments, etc., can solve the problems of radian value variation, inability to measure the radian of continuous casting rolls, and large changes in the working conditions of continuous casting rolls, so as to ensure normal operation. , The effect of ensuring the quality of the casting billet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

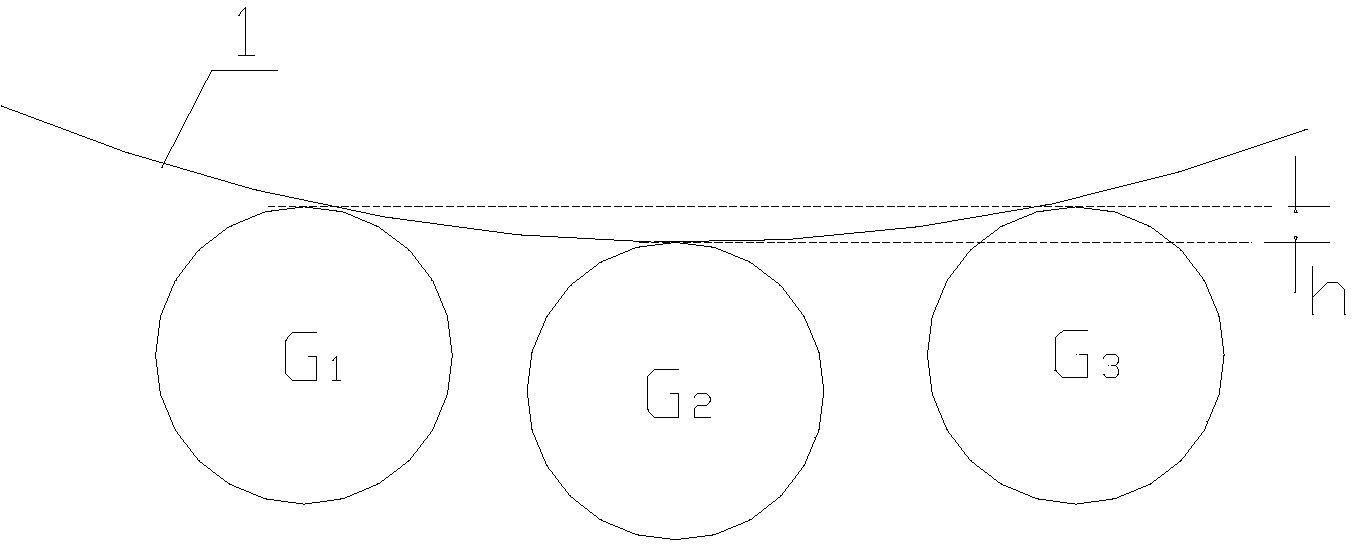

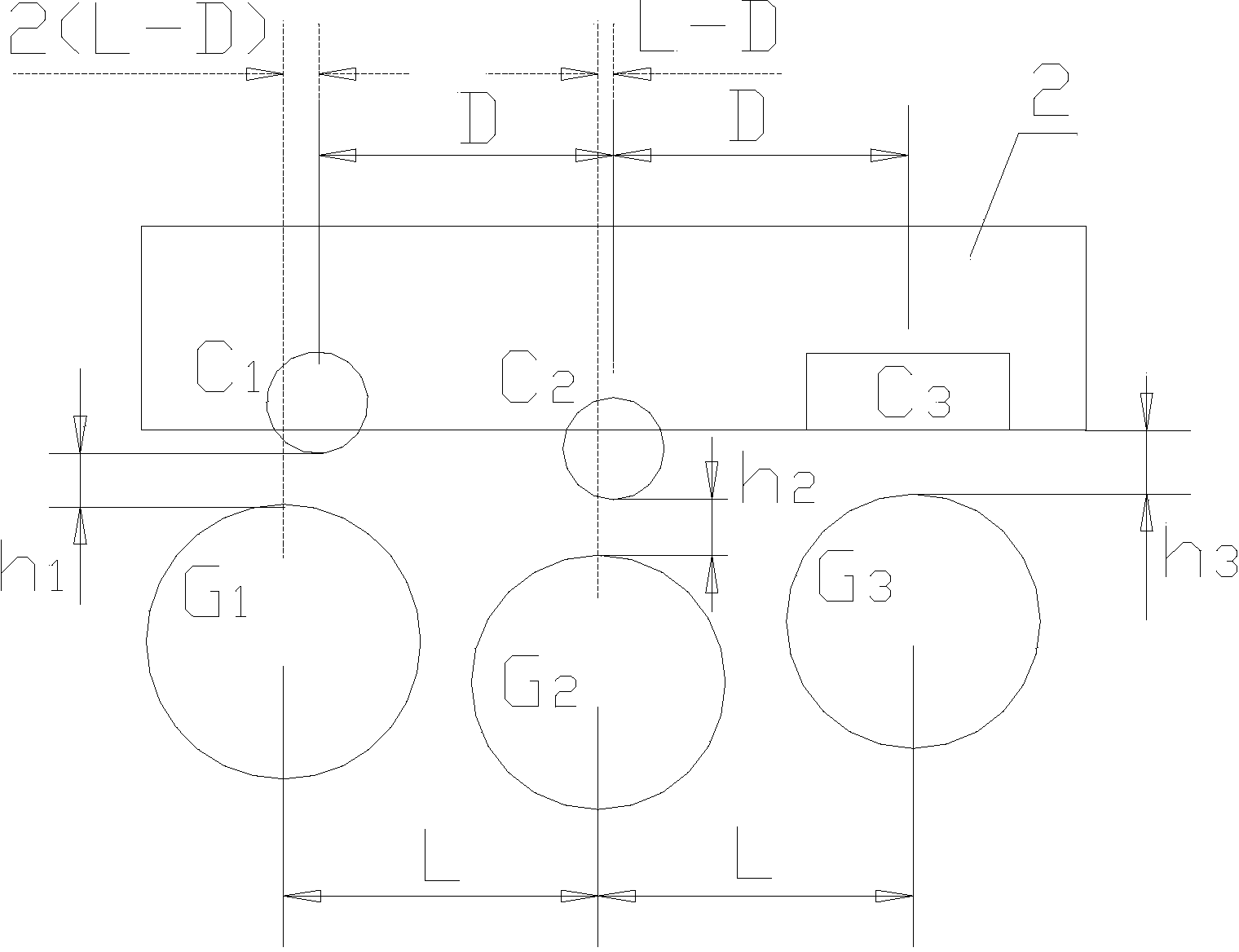

[0021] like figure 2 As shown, the online measurement method of the outer arc roll radian of the continuous casting machine of the present invention comprises the following steps:

[0022] Step 1. The roll gap meter 2 of the continuous casting machine advances in a straight line along the outer arc roll row, and the three probes C under the roll gap meter 2 1 、C 2 、C 3 Real-time detection of the distance from three adjacent outer arc rollers G 1 , G 2 , G 3 The distance from the roller surface to obtain the distance measurement value h 1 、h 2 、h 3 , respectively represent the distance between the gap meter 2 at the corresponding probe position and the outer arc roller;

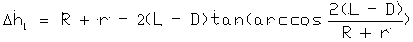

[0023] Step 2. It is known that the radius of the outer arc roller is R, the distance between the rollers is L, the radius of the spherical probe of the roll gap meter 2 is r, and the distance between the probes is D. Since the distance between the probes and the distance between the rollers is not eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com