600 MPa level automobile axle housing steel and production method thereof

A production method and technology of axle housing steel, applied in the field of steel rolling, can solve the problems of low strength level, unfavorable vehicles, thick thickness, etc., and achieve good yield strength and tensile strength, elongation and impact toughness, good strength and toughness, To achieve the effect of material thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention provides a 600MPa grade automobile axle housing steel, which is composed of (percentage by weight): C: 0.21%-0.26%; Si: 0.51%-0.6%; Mn: 1.1%-1.5%; Al: 0.01%- 0.06%; P: ≤0.02%; S: ≤0.01%; V: 0.05%-0.06%; N: 0.012%-0.016%; the rest is Fe and unavoidable impurities, among which, V:N≤5:1.

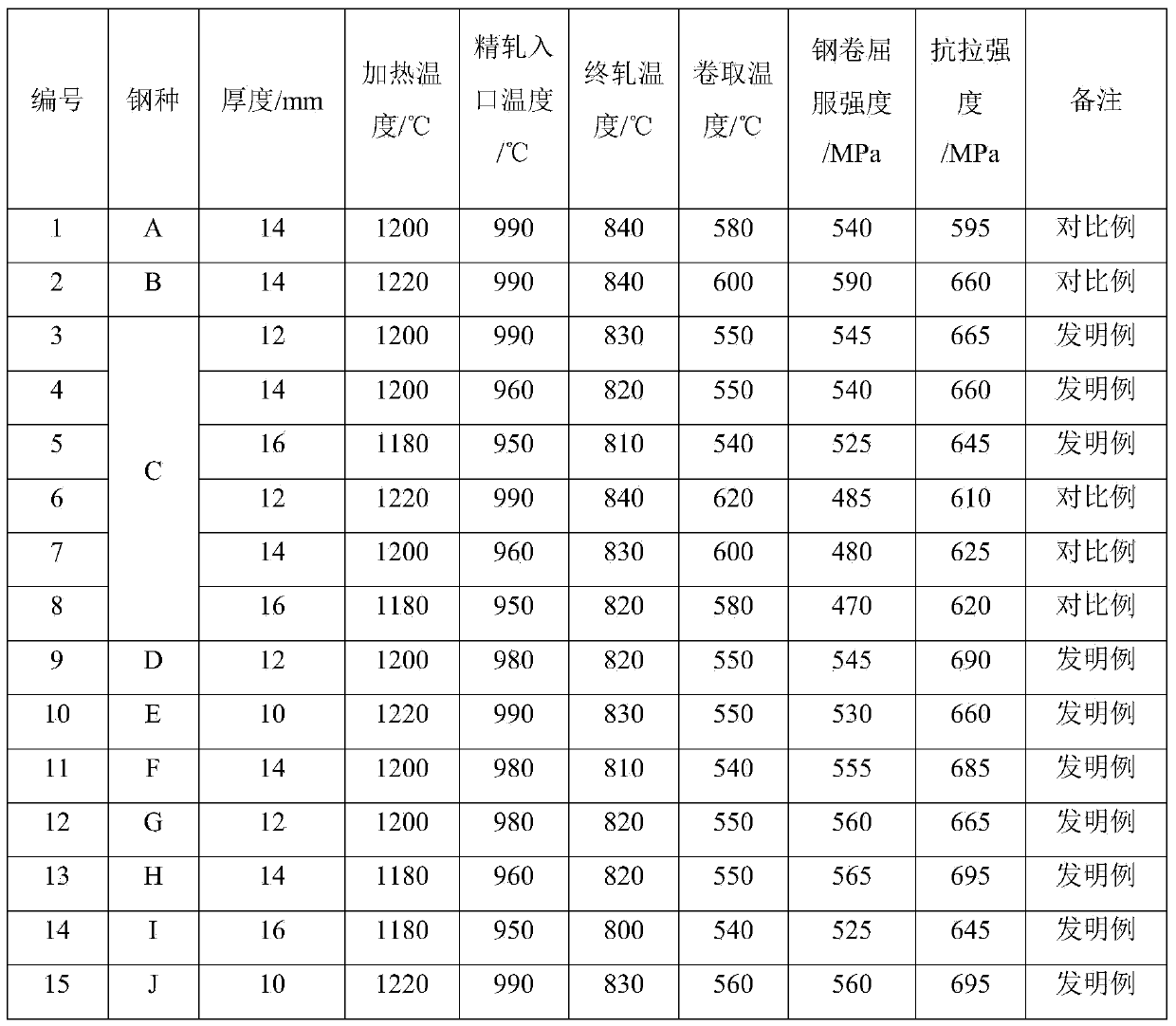

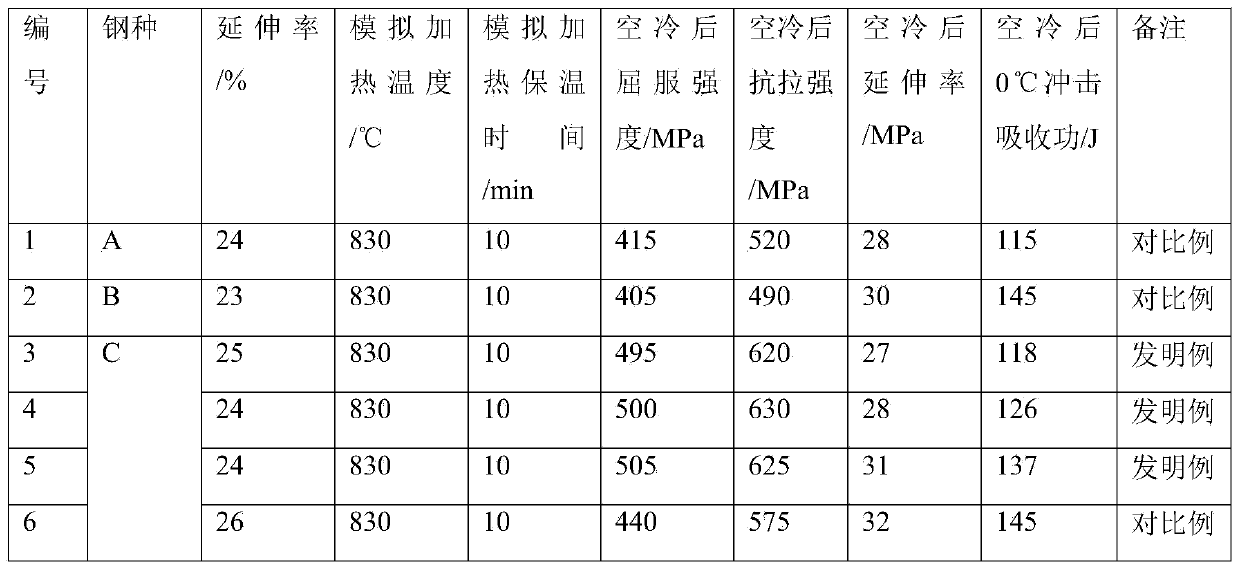

[0030] In practical application, depending on the type of steel, it has different composition content. Please refer to Table 1 below, which is the composition list of different steel types.

[0031]In order to better illustrate and explain the present invention, the composition of the comparative example (the existing steel type) and the composition of the invention example (the steel type involved in the present invention) are listed in Table 1 for comparison.

[0032] Table 1

[0033] Steel No.

Embodiment 2

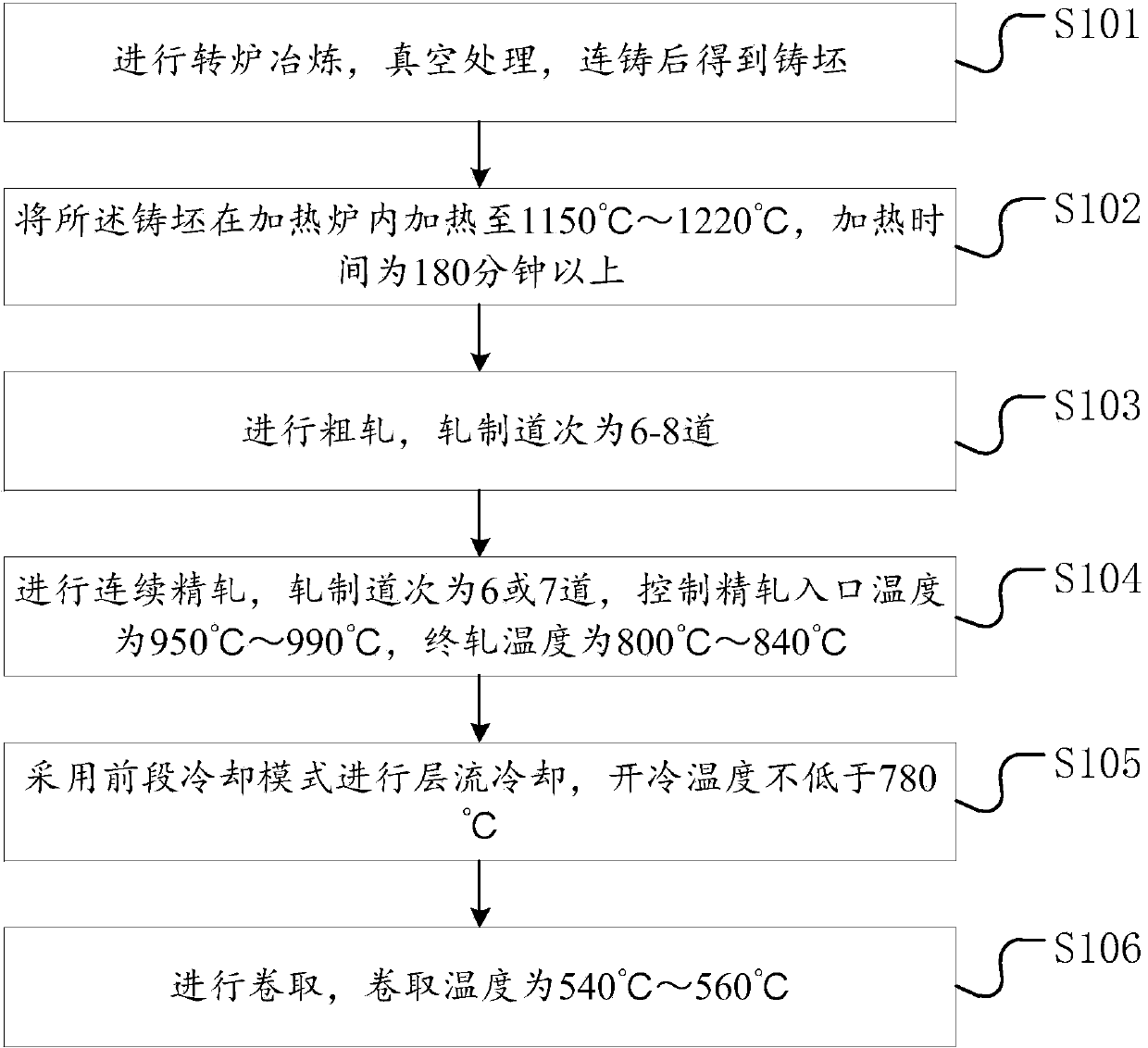

[0035] A kind of production method of 600MPa grade automobile axle housing steel provided by the invention, please refer to below figure 1 , is a flow chart of a specific production method in the embodiment of the present application, specifically as follows.

[0036] S101, performing converter smelting, vacuum treatment, and continuous casting to obtain a billet.

[0037] The composition of the slab is (weight percent): C: 0.21%-0.26%; Si: 0.51%-0.6%; Mn: 1.1%-1.5%; Al: 0.01%-0.06%; P: ≤0.02% ; S: ≤0.01%; V: 0.05%-0.06%; N: 0.012%-0.016%;

[0038] S102, heating the cast slab to 1150° C. to 1220° C. in a heating furnace, and the heating time is more than 180 minutes.

[0039] S103, rough rolling is carried out, and the rolling pass is 6-8 passes.

[0040] S104, performing continuous finish rolling with 6 or 7 rolling passes, controlling the finish rolling entrance temperature to be 950°C-990°C, and the finish rolling temperature to be 800°C-840°C.

[0041] S105, use the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com