Cogged ingot continuous casting crystallizer protecting slag and preparation method thereof

A technology of continuous casting mold and mold slag, applied in the field of iron and steel smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of mold powder for bloom continuous casting mold of the present invention comprises the following steps:

[0032] (1) Prepare the basic slag required for the preparation of mold flux premelt by weight percentage SiO 2 30-35%, CaO 25-30%, MgO 2.5-3.5%, Fe 2 o 3 1.5-2.5%, Al 2 o3 3.5-4.5%, carry out batching, stirring, pelletizing, drying in the air, so that the moisture content of pellets is ≤4%.

[0033] (2) After melting the ball forming material, water quenching is carried out, and the particle size is controlled at ≤5cm.

[0034] (3) drying the water-quenched material obtained in the above step (2) until the water content is ≤1%, ball milling, and the grinding particle size is less than 150 mesh to obtain mold slag premelt.

[0035] (4) Mix mold slag premelt, auxiliary materials, and carbonaceous materials in proportion, add binder, mix evenly in a conical agitator, and water mill to make slurry; when slurry is transported, the working p...

Embodiment 1

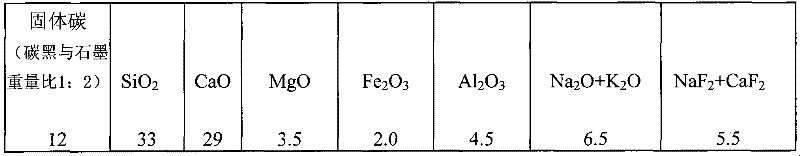

[0062] Example 1: Bloom 27SiMn Continuous Casting Slab Mold Mold Flux

[0063] The main chemical composition of the pre-melted hollow particle mold powder is in weight percentage, and the balance is binder and water.

[0064]

[0065] The preparation method comprises the following steps:

[0066] (1) Prepare the basic slag required for the preparation of mold flux premelt by weight percentage SiO 2 33%, CaO 29%, MgO3.5%, Fe 2 o 3 2.0%, Al 2 o 3 4.5%, batching, stirring, pelletizing, and drying to make the moisture content of pellets ≤ 4%.

[0067] (2) After melting the pelletized material, water quenching is carried out, and the particle size is controlled at ≤5cm. Red material or powder ash is not allowed to be mixed in it, so that the composition of the water quenching material is uniform.

[0068] (3) The water-quenched material is dried until the water content is ≤1%, ball milled, and the grinding particle size is less than 150 mesh to obtain mold slag premelt. ...

Embodiment 2-4

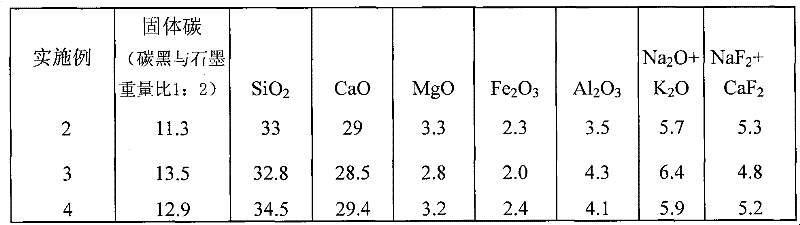

[0072] Examples 2-4, the preparation method is the same as that of Example 1, the difference is that the weight percentages of the main chemical components of the mold flux ingredients are as follows:

[0073]

[0074] The balance is granulation binder and moisture etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com