Horizontal conticaster and technique of billet withdrawal

A technology of horizontal continuous casting and slab casting, which is applied in the field of metal horizontal continuous casting machine and its casting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

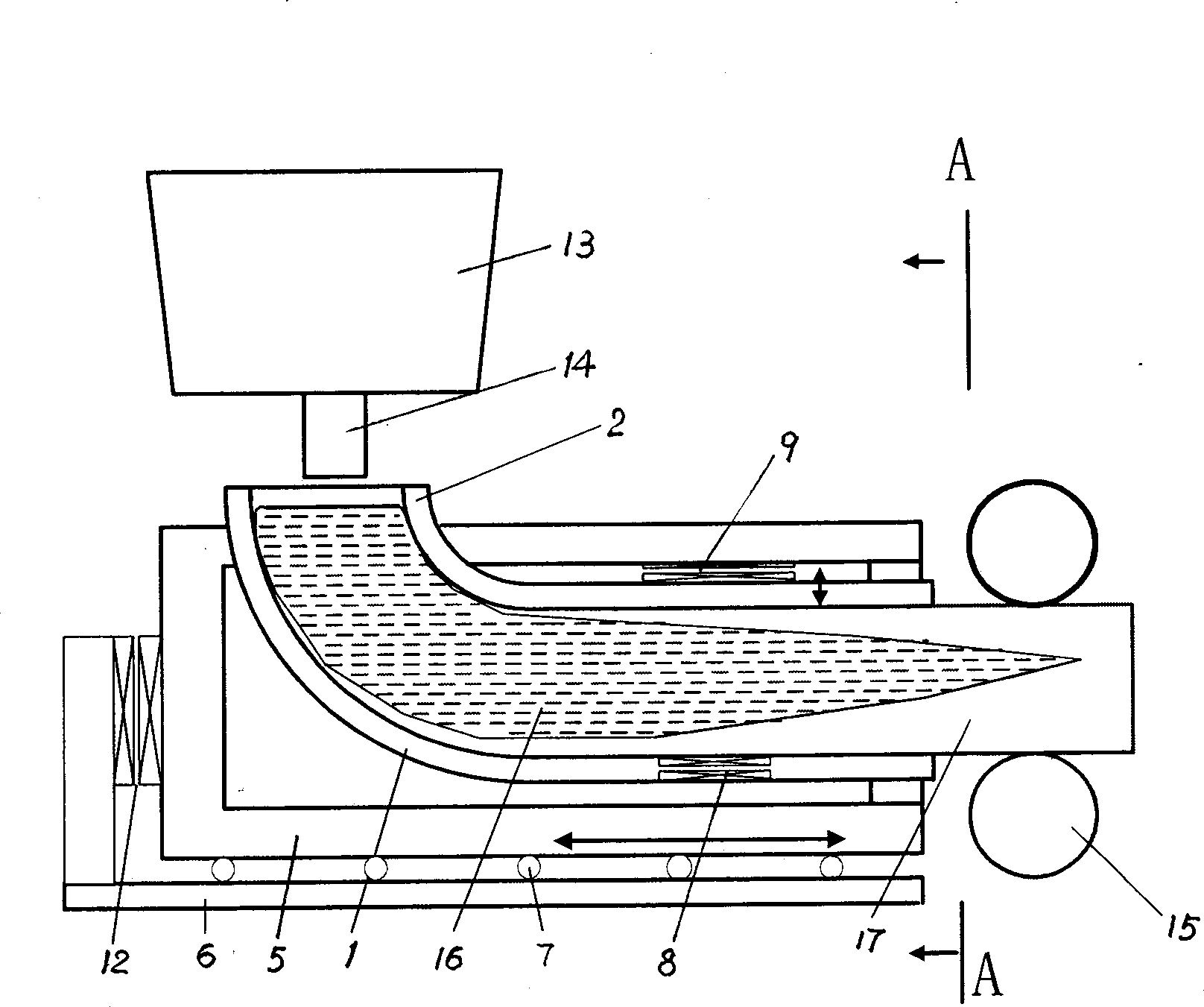

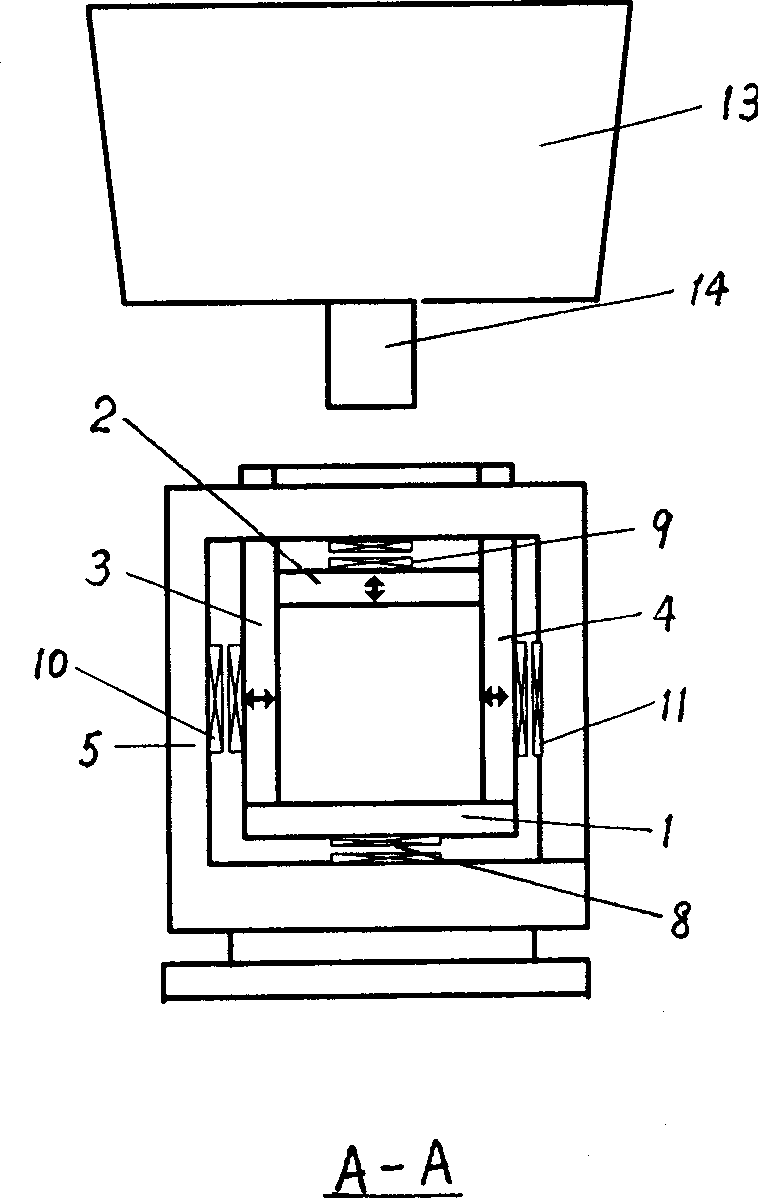

[0023] Embodiments of the present invention are described in further detail below in conjunction with accompanying drawings:

[0024] figure 1 and figure 2 Shown is the structure of an embodiment of the horizontal continuous casting machine of the present invention, which is used for continuous casting of billets. The crystallizer consists of a bottom (outer arc) copper plate 1, an upper (inner arc) copper plate 2, a left copper plate 3 and a right copper plate 4 to form a combined mold, forming a movable casting cavity; the combined mold is fixed on the frame 5 Among them, the frame 5 is supported on the plane bearing 7 of the frame 6; the head of the combined crystallizer is an arc-shaped section, and the horizontal section is below the arc-shaped section. The horizontal length of the horizontal section is 1200mm, and the horizontal section occupies a horizontal The casting cavity mold in the rear stage with a direction length of more than 3 / 4 (about 1000mm) is a straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com