Oil cooling system for double-chamber vacuum oil quenching furnace

An oil cooling system and cooling system technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of inability to adjust the speed of quenching oil cooling, inconvenient maintenance, and lack of direction in the flow of quenching oil, so as to ensure uniform cooling performance, easy maintenance and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

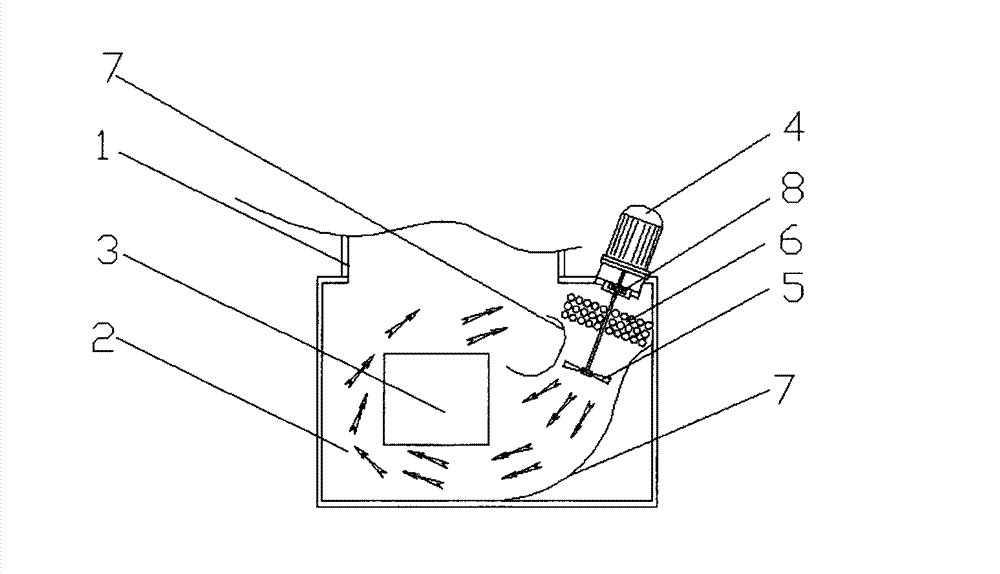

[0014] figure 1 The oil cooling system of a double-chamber vacuum oil quenching furnace shown includes a furnace body 1 and an oil tank 2. The oil tank 2 is arranged under the furnace body 1, and quenching oil is stored therein. The workpiece 3 to be quenched is placed in the oil tank 2. The oil tank 2 is provided with a quenching oil cooling device, including a stirring motor 4, an impeller 5 and a heat exchanger 6. The heat exchanger 6 is arranged on the transmission shaft of the stirring motor, and the impeller 5 is arranged at the end of the transmission shaft of the agitator motor. In order to improve the cooling effect of the workpiece, the convenience of use and maintenance, and the diversion of the quenching oil, the stirring motor is installed obliquely above the oil tank; both sides of the impeller in the oil tank 2 are provided with annular deflectors 7, and the two sides of the annular deflectors 7 are respectively connected to the The two sides of the oil tank 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com