A manufacturing method for quenching heat treatment of super-wide and extra-thick steel containment nuclear power steel

A manufacturing method and containment technology, which are applied in heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve the problems of super-wide and extra-thick plate quenching technology without relevant guidance, insufficient cooling capacity of quenching heat treatment technology, thickness and width directions Uneven performance and other problems, to achieve the effect of shortening the quenching vapor film stage, ensuring uniform heating, and ensuring homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

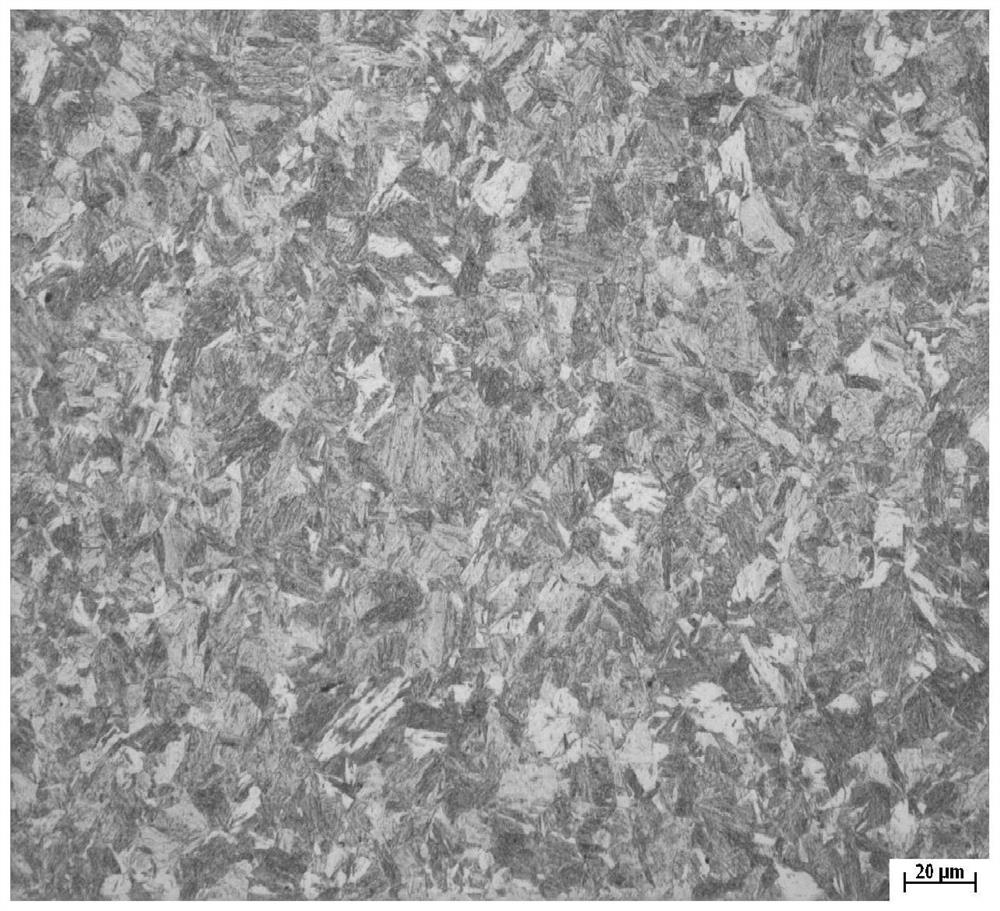

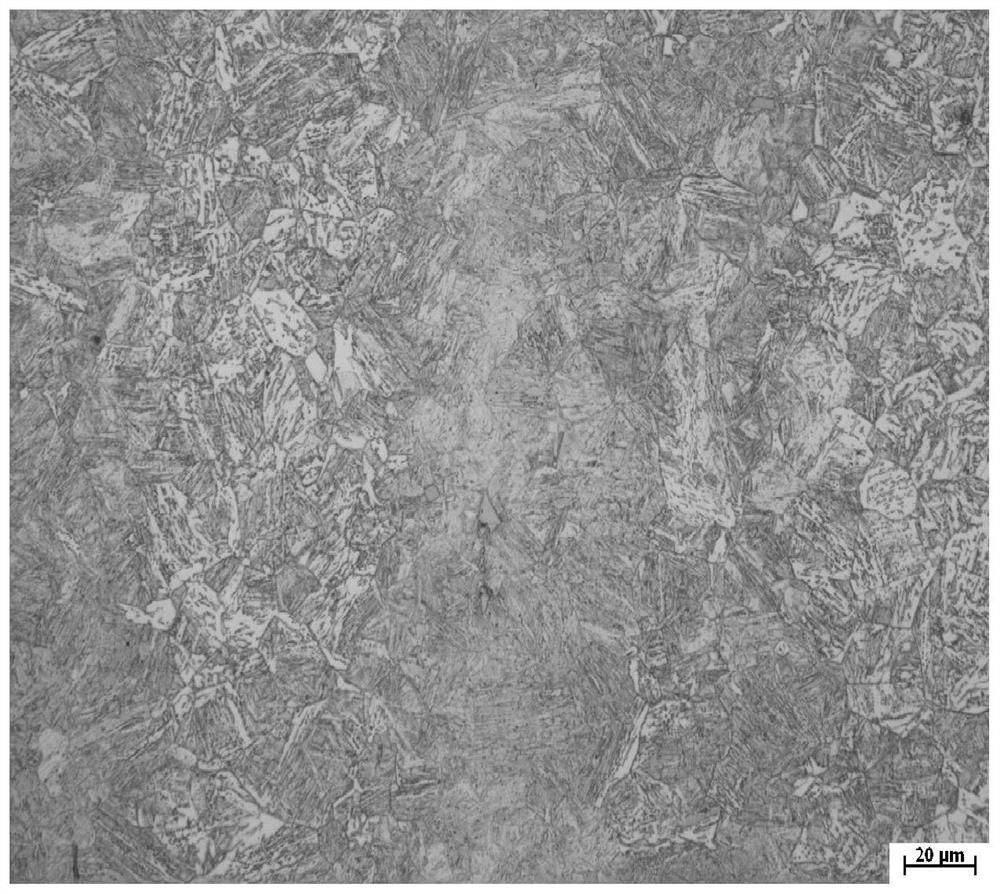

Image

Examples

Embodiment Construction

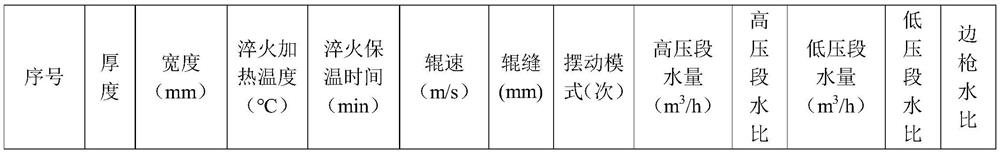

[0017] Hereinafter, the manufacturing method of the present invention will be further described in detail in combination with specific cases. The quenching heat treatment process parameters of each case are shown in Table 1.

[0018] Table 1 Quenching heat treatment process parameters

[0019]

[0020]

[0021] Embodiment 1-5 in the table 1 all adopts the manufacturing method of the present invention to carry out, and comparative example 1 does not carry out side gun nozzle cooling according to the requirements of the present invention, and comparative example 2 does not control the water quantity of high and low pressure sections according to the requirements of the present invention, and comparative example 3 Oscillation is not performed as required by the invention.

[0022] The tempering performance parameters of the steels in the above cases are shown in Table 2 and Table 3, where all cases were tempered at 650°C.

[0023] Table 2 Steel width direction properties ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com