Engine body for hot air engine

A technology of hot air engine and fuselage, which is applied in the direction of hot air variable displacement engine devices, machines/engines, mechanical equipment, etc., and can solve problems such as uneven temperature of working medium, uneven cooling effect, and complicated layout of cooling water pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

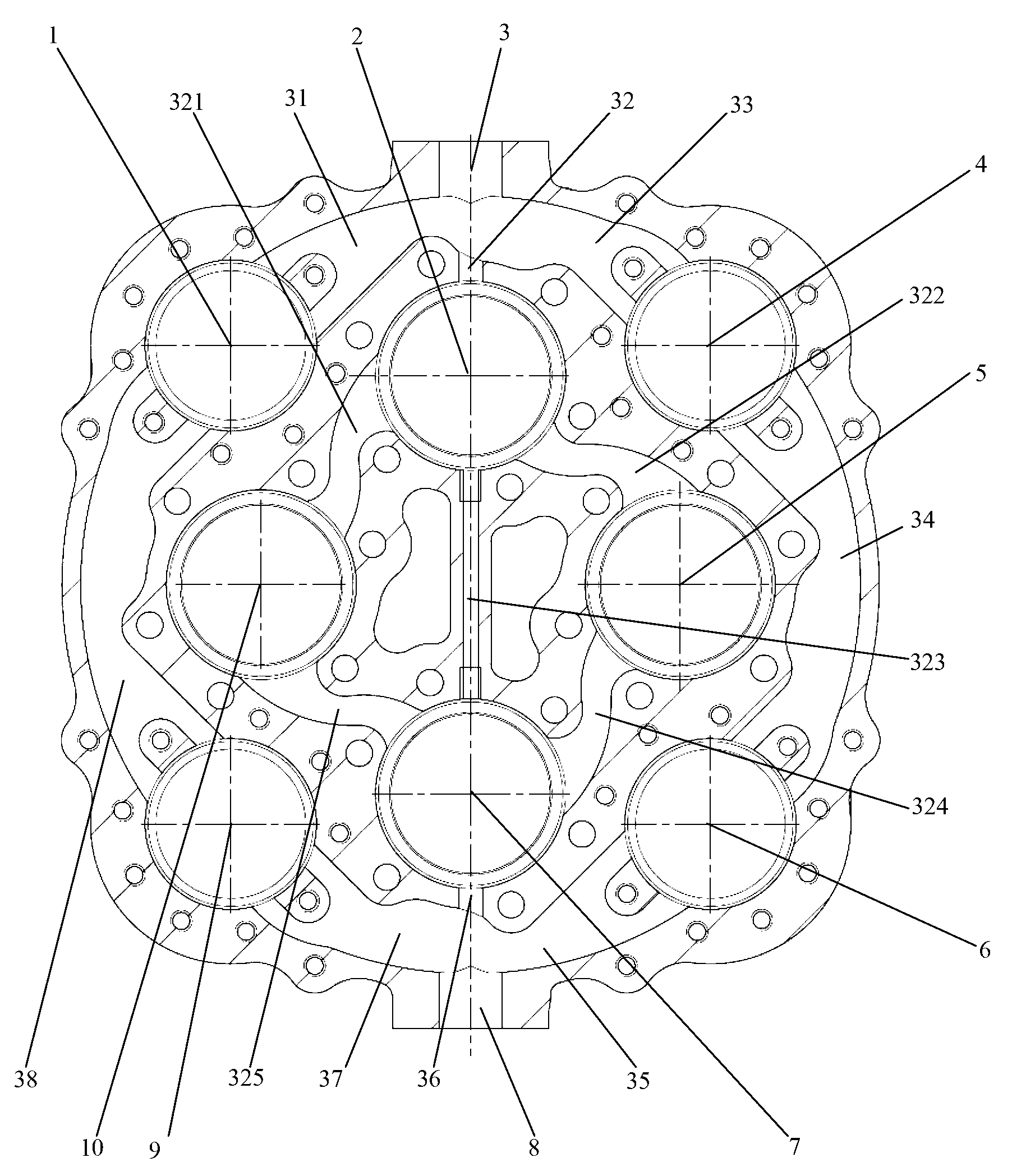

[0019] figure 1 Shown is an embodiment of the present invention. The fuselage is integrated. In order to improve production efficiency and reduce costs, the fuselage is integrally cast from cast aluminum and then machined. The fuselage is provided with a cylinder liner installation hole for installing the cylinder liner of the heat engine and a cooler installation hole for installing the cooler, and the body is suitable for the heat engine in which the cylinder liner and the cooler are arranged separately. The cylinder liner installation holes on the fuselage are arranged in a square shape, and a cooler installation hole is arranged near each cylinder liner installation hole.

[0020] A cooling water flow channel and a working medium flow channel are also arranged on the fuselage. For the convenience of peripheral piping layout, the fuselage is only provided with a cooling water inlet 3 and a cooling water outlet 8 . In order to improve the cooling effect, the cooling water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com