High-power laser diode array throttling micro-evaporative refrigeration heat sink

A laser diode, evaporative refrigeration technology, applied in the directions of lasers, phonon exciters, laser parts, etc., can solve the problems of high-power laser diode arrays that work efficiently, uneven cooling of high-power laser diode arrays, and high-precision heat sink fabrication. Difficulties and other problems to achieve the effect of ensuring normal and efficient work, ensuring cooling uniformity, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

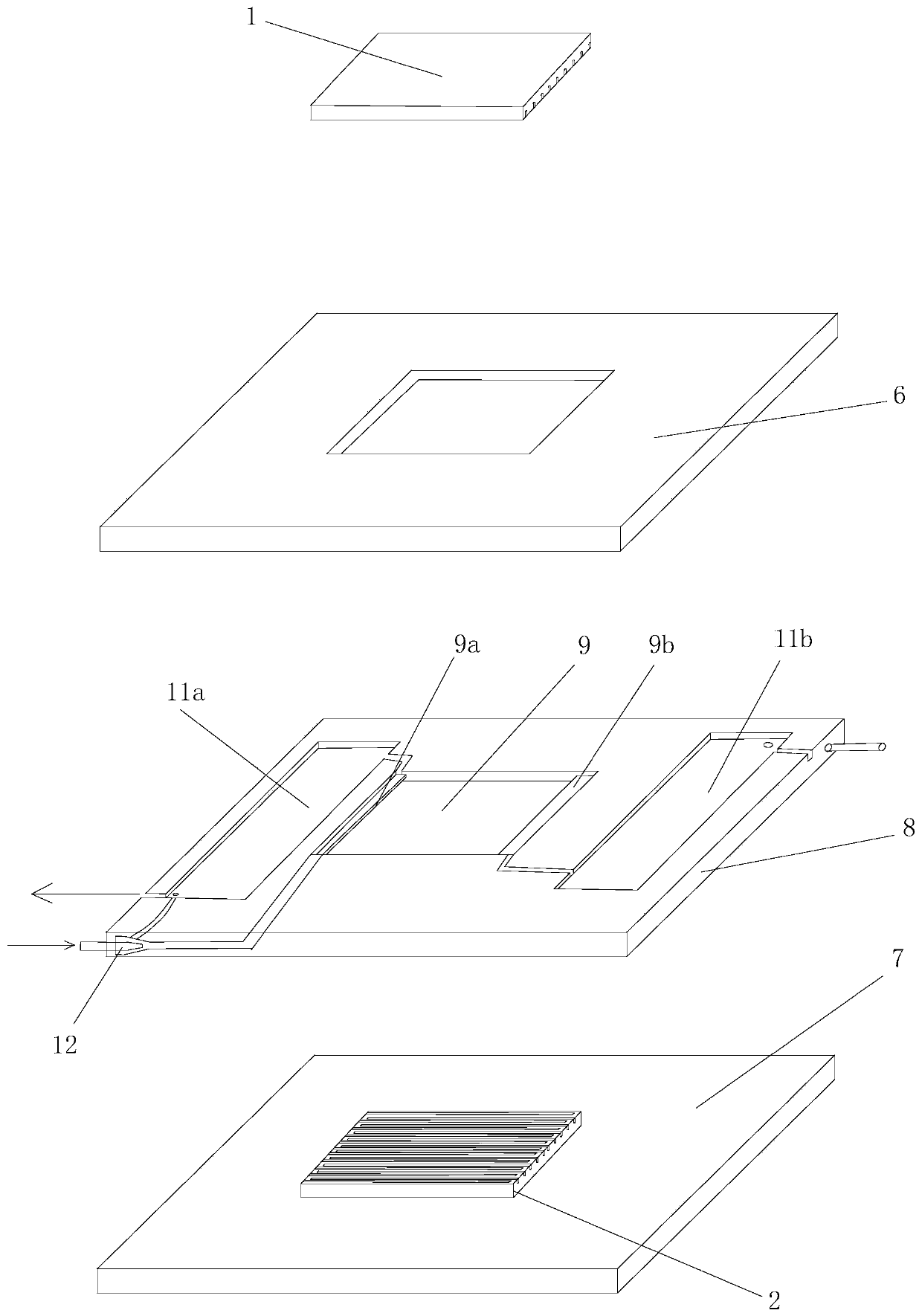

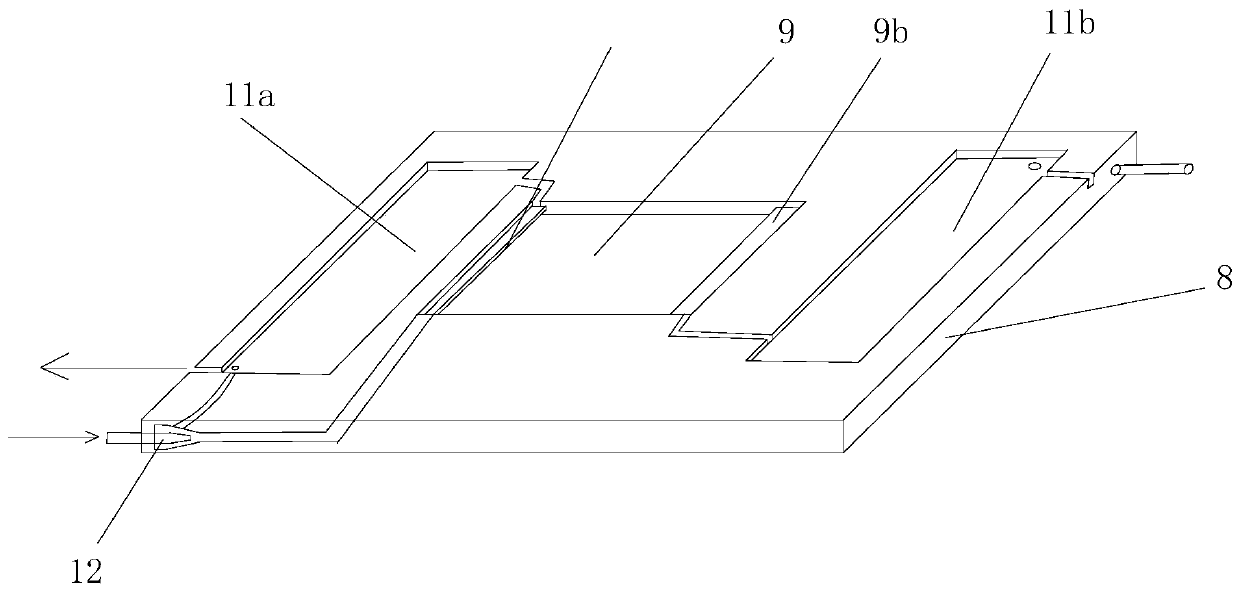

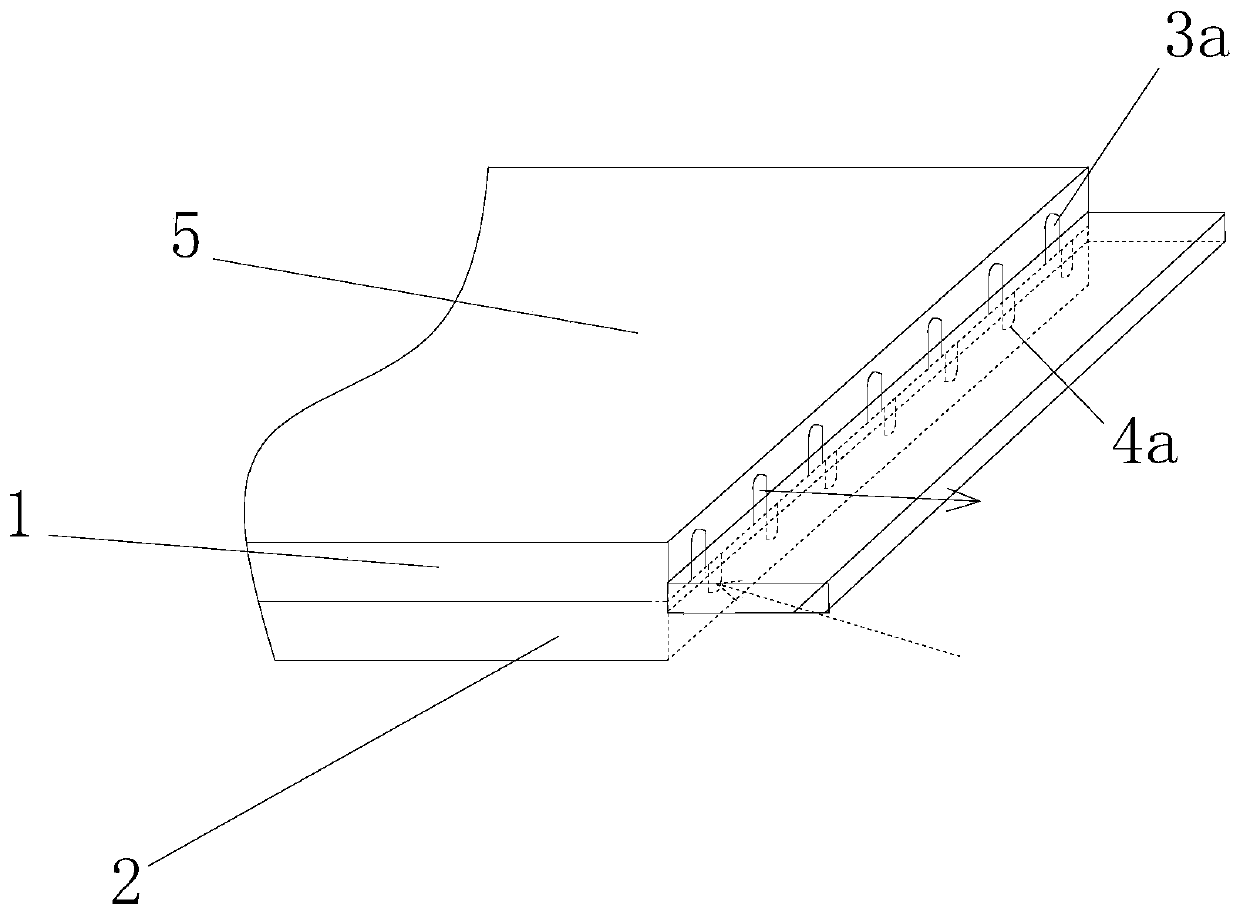

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the enclosure in the present invention, image 3 It is a structural schematic diagram of the partition board installation in the present invention, Figure 4 It is a structural schematic diagram of the flow direction of each flow channel of the present invention. As shown in the figure, the high-power laser diode array throttling micro-evaporation refrigeration heat sink in this embodiment; at least includes an upper heat sink plate 1 and a lower heat sink plate 2 arranged overlappingly The bottom surface of the heat sink upper plate 1 is provided with a plurality of upper bar-shaped grooves 3, and the top surface of the heat sink lower plate 2 is provided with a plurality of lower bar-shaped grooves 3 corresponding to each other. Groove 4, the single upper bar-shaped groove 3 and the corresponding lower bar-shaped groove 4 are dislocated and conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com